Extruded and rolled polyphenylene sulfide copper-clad plate material and preparation method thereof

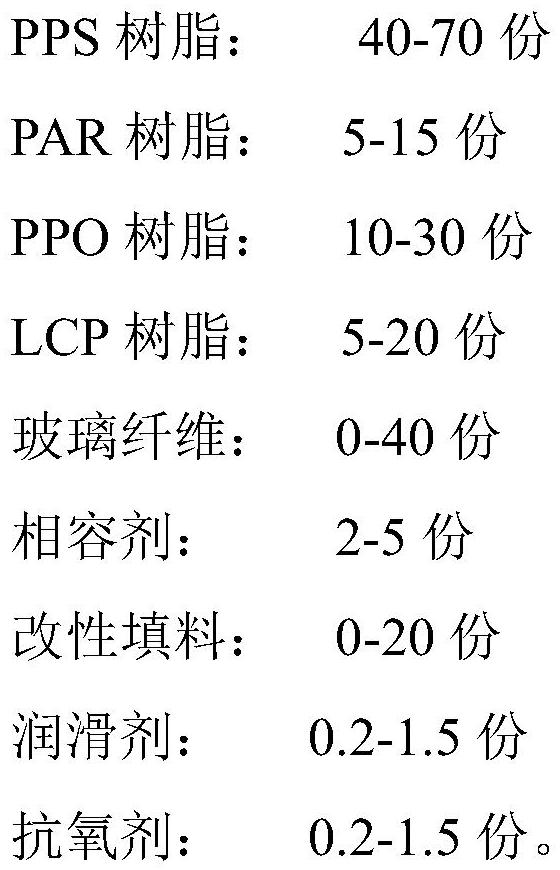

A polyphenylene sulfide and copper clad laminate technology is applied in the field of extrusion and calendering of polyphenylene sulfide copper clad laminate materials and their preparation, which can solve the problems of high total cost, lack of continuous one-step production mode, etc. , Low thermal expansion coefficient, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0062] A preparation method for extruding and calendering polyphenylene sulfide (PPS) copper-clad laminate material, comprising the following steps:

[0063] (1) After preparing the materials according to the components and ratios described in Examples 1-9, except for the glass fiber, mix at high speed for 5 minutes through a high-speed mixer;

[0064] (2) The above-mentioned mixed material is granulated through a twin-screw extruder, glass fibers are added downstream of the twin-screw extruder, the twin-screw speed is 550 rpm, and the temperature is 295°C;

[0065] (3) Finally, the above-mentioned granules are melted and plasticized by a twin-screw extruder, extruded from a die (1.0mm thick), shaped by a calender, and coated with copper online to form a PPS copper-clad laminate of a certain thickness.

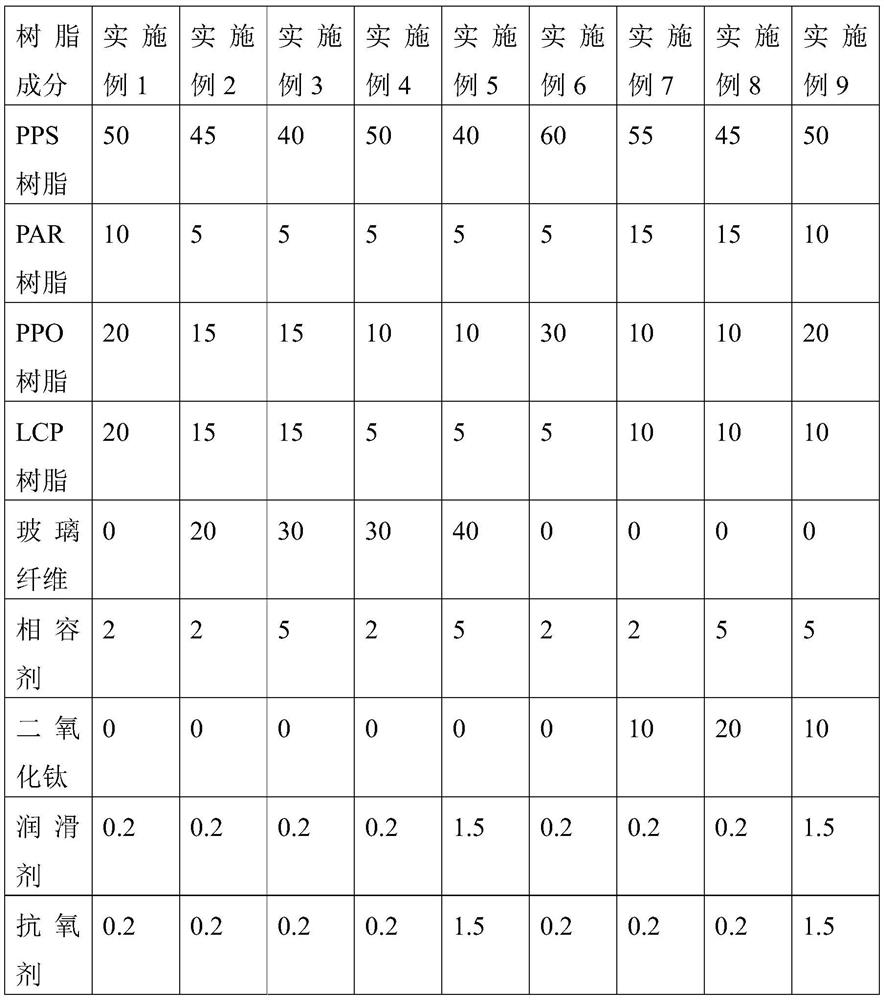

[0066] Table 1 Embodiment 1-9 formula

[0067]

[0068] Table 2 shows the properties of the extrusion-rolled polyphenylene sulfide (PPS) copper-clad laminate material obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com