Processing method of steel wire for armored cable

A technology of armored cables and processing methods, which is applied in the field of cable steel wires, can solve problems such as long project cycles, and achieve the effects of increasing C content, preventing intergranular corrosion, and reducing work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

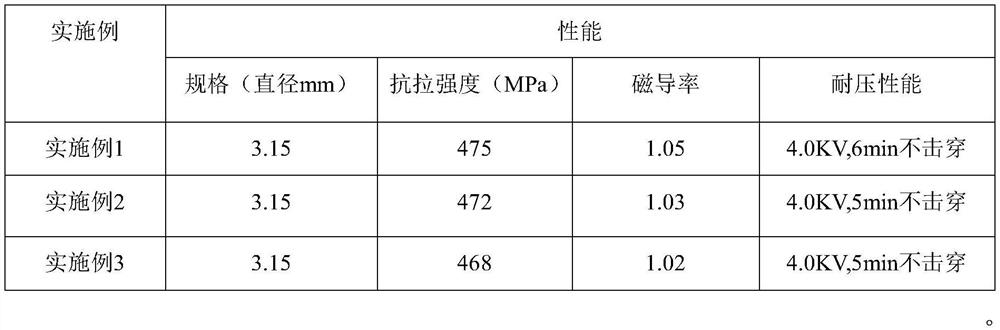

Examples

Embodiment 1

[0033] The steel wire for armored cable of the present embodiment, the processing step comprises:

[0034] (1) The raw material wire rod of 6.50mm diameter carries out peeling: Carry out peeling with 5-6m / minute speed on the peeling machine, raw material peeling removes surface defects, the surface is clean, without defect; The raw material wire rod in step (1) after peeling The diameter is 6.30mm; the chemical composition (smelting composition wt%) of the raw wire rod in the step (1) is: C 0.025wt%, Si 0.025wt%, Mn12.0wt%, P 0.035wt%, S 0.003wt%, Cr 15.00wt%, Ni6.00wt%, Cu 3.00wt%, C0.020wt%, Mo 0.2wt%, the sum of Ti, Nb and Ta is 0.01wt% (the three are mixed in any proportion), the balance is iron and unavoidable of impurities.

[0035](2) Film treatment: Carry out film treatment to the surface of the wire rod in a film tank equipped with a film solution, and then dry it; the concentration of the film agent is 1.03-1.13 (specific gravity); the temperature of the film solut...

Embodiment 2

[0042] The steel wire for armored cable of the present embodiment, the processing step comprises:

[0043] (1) The raw material wire rod of 6.50mm diameter carries out peeling: Carry out peeling with 5-6m / minute speed on the peeling machine, raw material peeling removes surface defects, the surface is clean, without defect; The raw material wire rod in step (1) after peeling The diameter is 6.30mm; the chemical composition (smelting composition wt%) of the raw wire rod in the step (1) is: C 0.010wt%, Si 0.020wt%, Mn10.00wt%, P0.005wt%, S0.001wt%, Cr 14.00wt%, Ni 5.00wt%, Cu 2.00wt%, C0.010wt%, Mo 0.2wt%, Ti, Ta (mixed in any ratio) 0.02wt%, the balance is iron and unavoidable impurities;

[0044] (2) Film treatment: Carry out film treatment to the surface of the wire rod in a film tank equipped with a film agent solution, and then dry; the concentration of the film agent is 1.02 (specific gravity); the temperature of the film agent solution is 65 ° C; and here The film treat...

Embodiment 3

[0051] The steel wire for armored cable of the present embodiment, the processing step comprises:

[0052] (1) The raw material wire rod of 6.50mm diameter carries out peeling: Carry out peeling with 5-6m / minute speed on the peeling machine, raw material peeling removes surface defects, the surface is clean, without defect; The raw material wire rod in step (1) after peeling The diameter is 6.30mm; the chemical composition (smelting composition wt%) of the raw wire rod in the step (1) is: C0.015wt%, Si0.005wt%, Mn8.00wt%, P0.020wt%, S0.001wt%, Cr13 .00wt%, Ni4.00wt%, Cu 1.50wt%, C0.010wt%, Mo 0.1wt%, Ti, Nb and Ta (mixed in any ratio) 0.01wt%, the balance is iron and unavoidable impurities;

[0053] (2) Film treatment: Carry out film treatment to the surface of the wire rod in a film tank equipped with a film solution, and then dry; the concentration of the film agent is 1.02 (specific gravity); the temperature of the film solution is 60°C; and the The film treatment adds a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com