Preparation method of avalanche photodetector

An avalanche photoelectric and detector technology, applied in the field of photoelectric detectors, can solve the problems of inconsistency of detectors, difficult diffusion of Zn, and reduced yield, etc., and achieves reduction of tunneling dark current, high crystal quality, and reduction of electric field strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

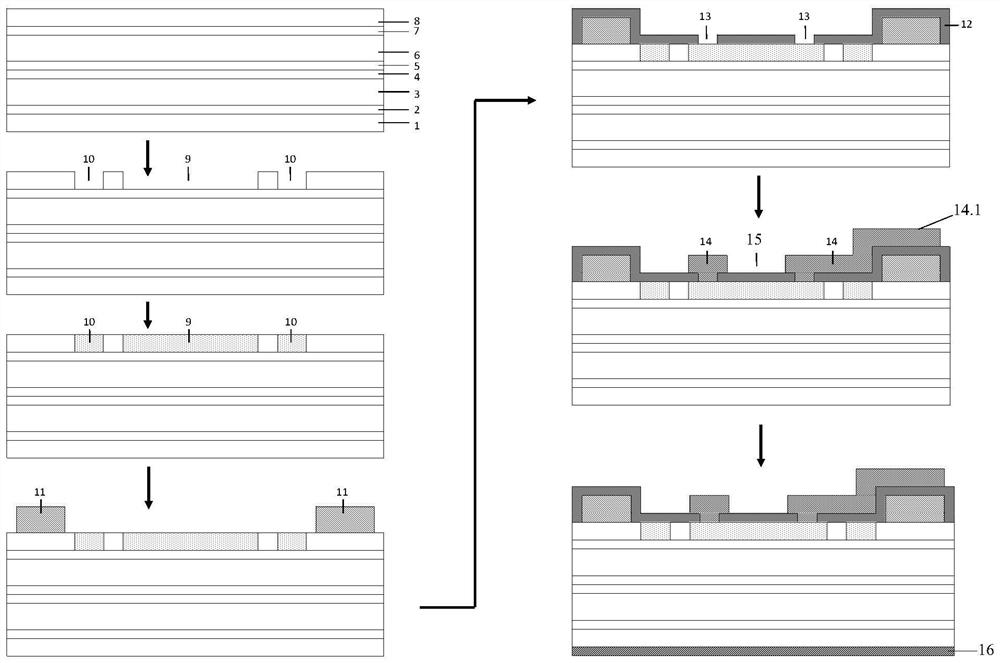

[0052] Such as figure 1 Shown, a kind of preparation method of avalanche photodetector comprises the following steps:

[0053] Step 1: On the p-type InP substrate 1, grow the p-type InP buffer layer 2, InP 0.53 Ga 0.47 As absorption layer 3, In 1-x-y Al x Ga y As bandwidth gradient layer 4, p-type In 0.52 Al 0.48 As charge control layer 5, In 0.52 Al 0.48 As multiplication layer 6, In x Ga 1-x As y P 1-y The stop layer 7 and the p-type InP capping layer 8 are etched.

[0054] Step 2: Using SiO 2 The patterned hard mask uses an etching method to etch the p-type InP cap layer 8 in a specific area. The etched area includes a central area and one or more annular areas surrounding the central area. In this embodiment, it includes An annula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com