Full-load denitration device and denitration method for circulating fluidized bed boiler

A circulating fluidized bed, full-load technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as failure to meet ultra-low emission standards and decline in denitrification efficiency, achieve small space occupation, and reduce ozone Energy consumption and the effect of improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

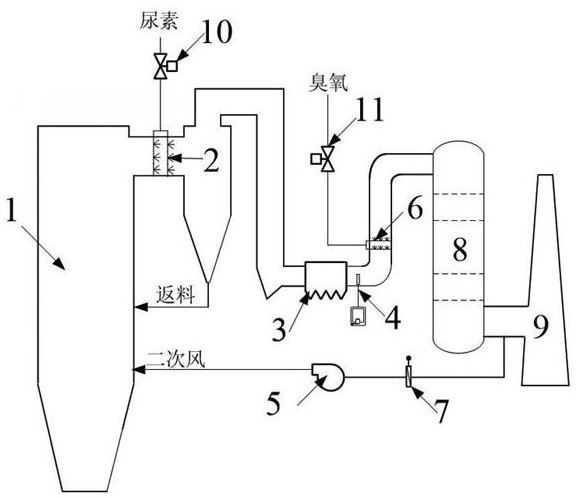

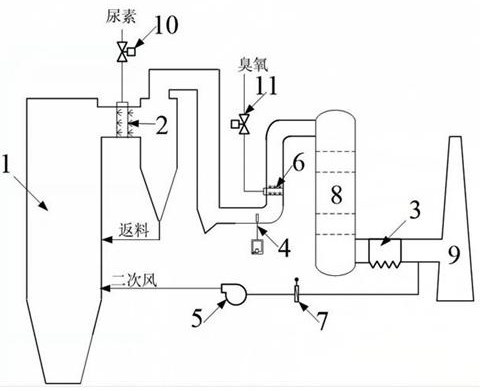

[0032] A circulating fluidized bed boiler full-load denitrification device, which consists of: boiler 1, SNCR spray gun 2, dust collector 3, NOx monitor 4, recirculation fan 5, ozone spray gun 6, desulfurization tower 8 and chimney 9;

[0033] The SNCR spray gun is inserted into the outlet flue of the boiler furnace, and the flue gas of the boiler furnace is discharged through the chimney after passing through the dust collector and the desulfurization tower;

[0034] The baffle valve is arranged in the flue leading out between the desulfurization tower and the chimney, and the recirculation fan is arranged after the baffle valve.

[0035] The ozone spray gun is arranged in the flue between the NOx monitor and the desulfurization tower;

[0036] A recirculation pipeline is drawn between the desulfurization tower and the chimney, a baffle valve 7 is arranged on the recirculation pipeline, and a recirculation fan 5 is arranged behind the baffle valve;

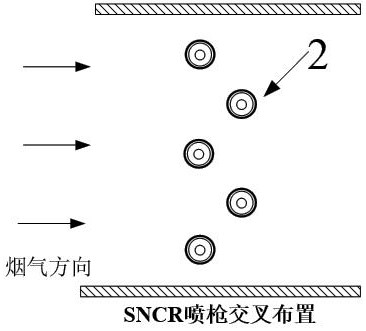

[0037] The SNCR spray gu...

Embodiment 2

[0040] According to the circulating fluidized bed boiler full-load denitrification device described in embodiment 1, the desulfurization tower is a scrubber, the dust collector is arranged at the front flue of the scrubber, and the NOx monitor It is fixed at the rear flue of the dust collector.

Embodiment 3

[0042] According to the circulating fluidized bed boiler full-load denitrification device described in Example 1, the desulfurization tower is a semi-dry desulfurization tower, and the semi-dry desulfurization tower adopts a conventional bubble tower, and the dust collector is arranged in the The rear flue of the semi-dry desulfurization tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com