Innocent treatment system for solid waste triphenylphosphine oxide in electronic industry

A triphenylphosphine oxide, harmless treatment technology, applied in chemical instruments and methods, transportation and packaging, etc., can solve the problems of environmental pollution, inconvenient post-processing of cleaning agents, etc., to reduce production costs, low cost and fast speed The effect of solving and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

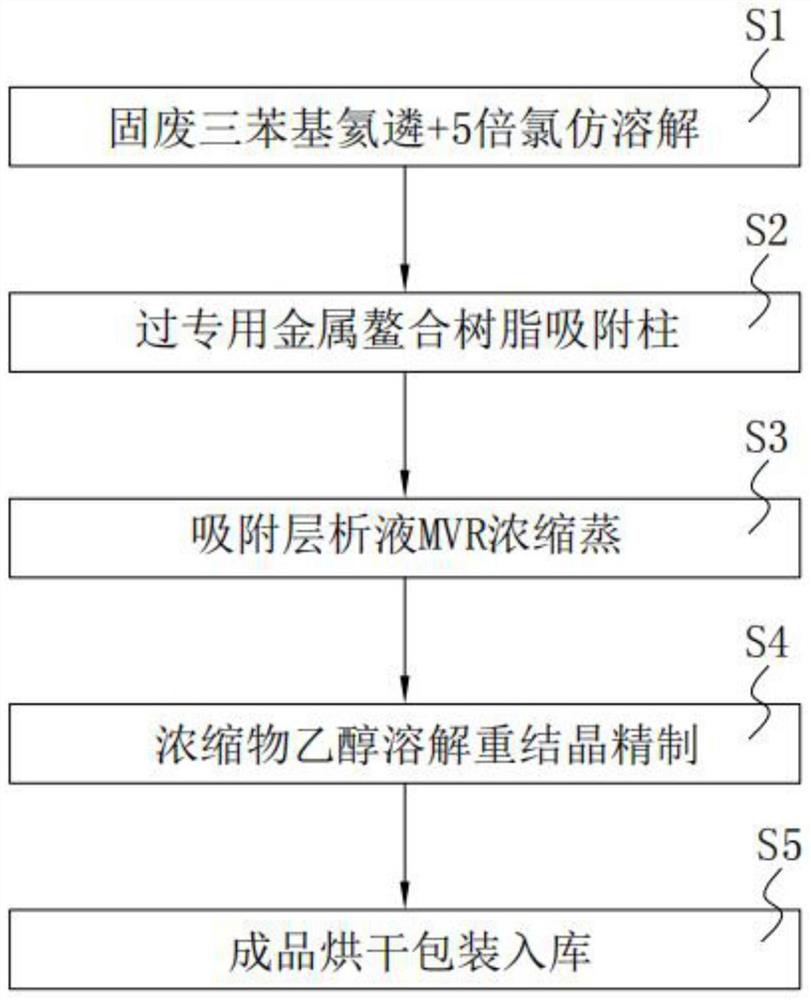

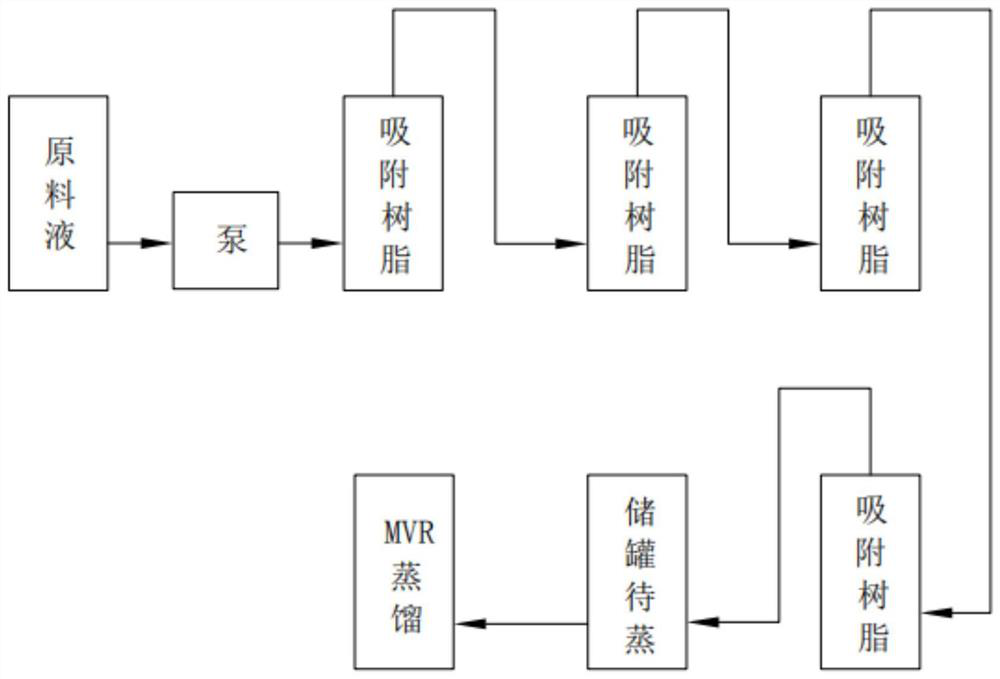

[0022] Please refer to figure 1 , figure 2 ,in, figure 1 A flow diagram of a preferred embodiment of the electronic industry solid waste triphenylphosphine oxide harmless treatment system provided by the present invention; figure 2 It is a schematic diagram of a preferred embodiment of the raw material liquid treatment process of the electronic industry solid waste triphenylphosphine oxide harmless treatment system provided by the present invention. The harmless treatment system for electronic industry solid waste triphenylphosphine oxide includes the following steps:

[0023] S1: Dissolving solid waste triphenylphosphine oxide + 5 times chloroform;

[0024] S2: through a special metal chelate resin adsorption column;

[0025] S3: The adsorption chromatography liquid MVR is concentrated and evaporated;

[0026] S4: The concentrate is refined by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com