Modified cellulose-based poly-surfactant, emulsifying viscosity reducer, preparation method of modified cellulose-based poly-surfactant and application of modified cellulose-based poly-surfactant and emulsifying viscosity reducer in viscosity reduction of thickened oil

A polymer-based surface agent, emulsification and viscosity-reducing technology, applied in modified cellulose-based surface-polymerization agent, heavy oil viscosity reduction, emulsification viscosity-reducer and its preparation field, can solve the difficult to achieve microbial influence, salt tolerance Poor performance, difficulty in separating microorganisms, etc., to achieve the effect of facilitating crude oil transportation and remarkable viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

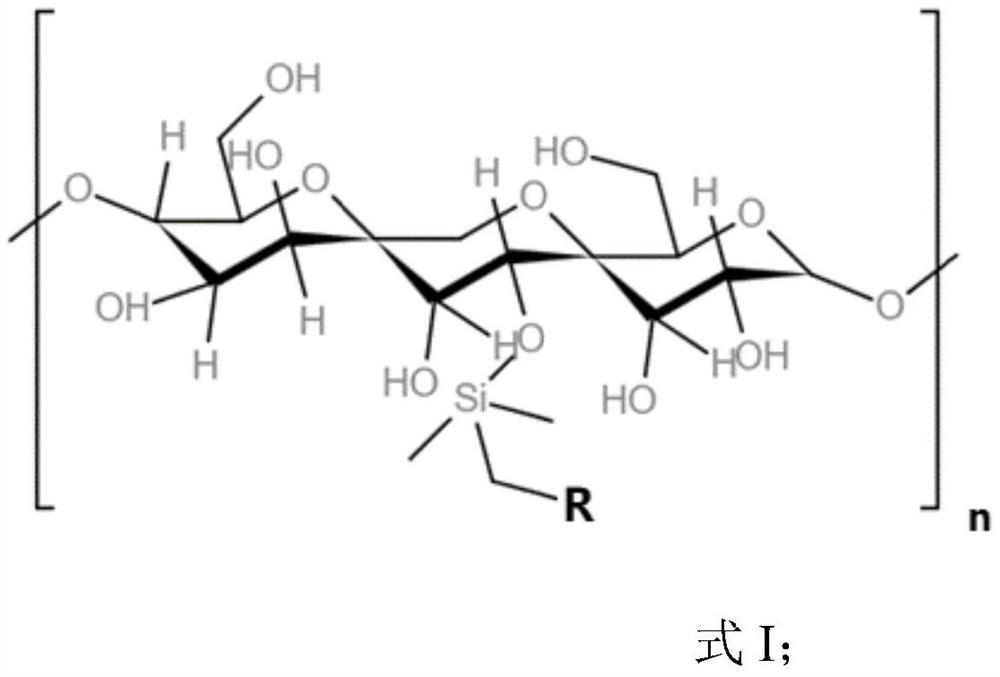

[0051]Embodiment 1 prepares modified cellulose-based polysurfactant

[0052] Proceed as follows:

[0053] Step (1) Weigh 10g of γ-methacryloxypropyltrimethoxysilane, disperse it in the mixed solution of 100g ethanol and water, wherein the mass ratio of ethanol and water is 9:1, add acetic acid to adjust the system The pH value is 4, stir at room temperature for 0.5h to disperse the modifier evenly;

[0054] Step (2) Weighing 5 g of carboxymethyl cellulose with a particle size of 100 nm and adding it to the dispersion prepared in step (1), stirring and reacting rapidly at a temperature of 50° C. for 1 h to obtain a double bond-modified cellulose solution;

[0055] Step (3) filtering and washing the mixed solution in step (2), drying the filter cake to obtain double bond modified cellulose powder;

[0056] Step (4) Weigh 5 g of double bond modified cellulose powder prepared in step (3) and disperse in 100 g of water.

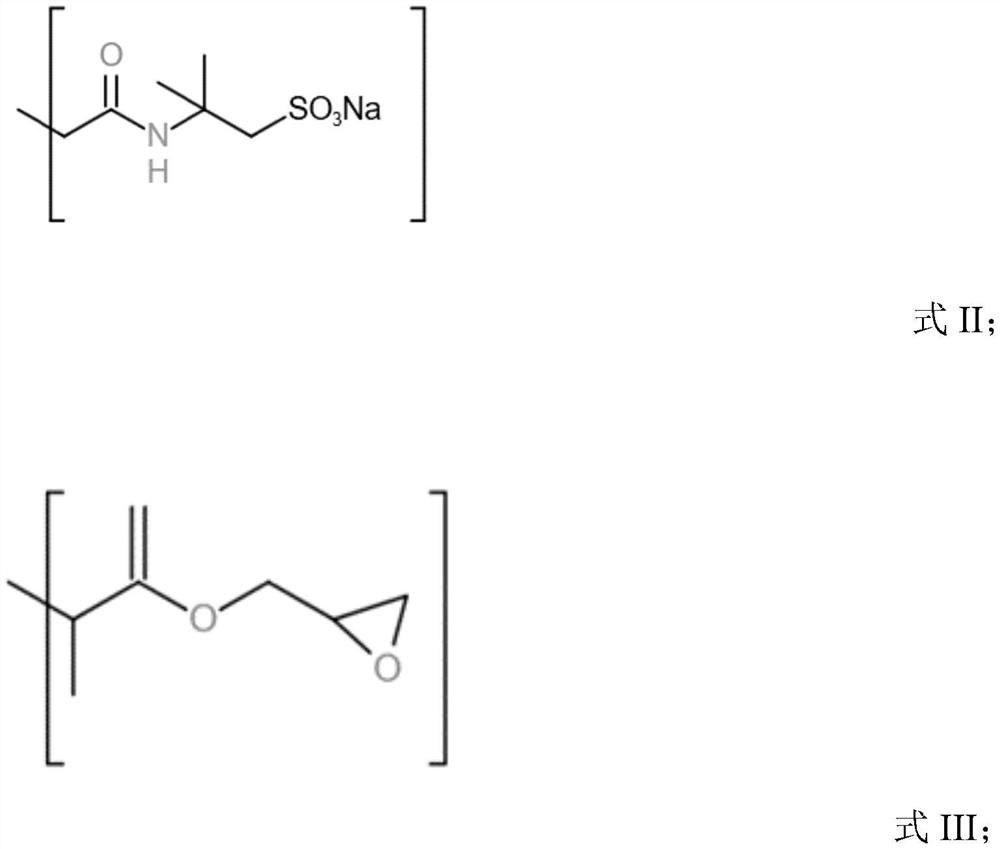

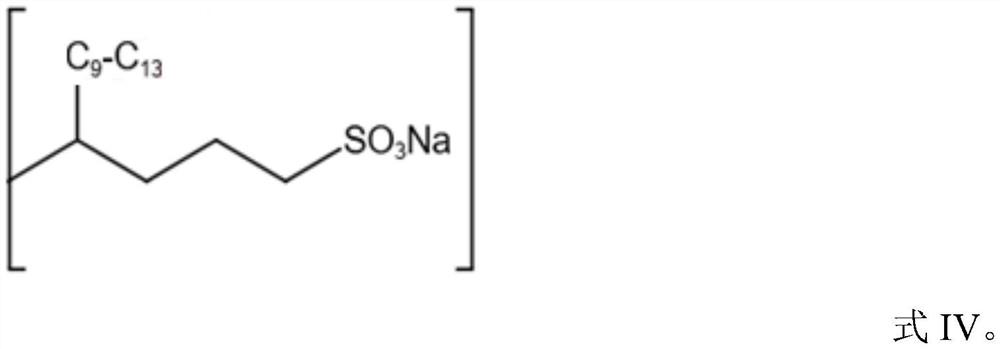

[0057] Step (5) Weigh 20 g of sodium a-olefin sulfonate a...

Embodiment 2

[0062] Embodiment 2 prepares emulsified viscosity reducer

[0063] Proceed as follows:

[0064] Add 10 g of fatty alcohol polyoxyethylene ether and 20 g of the modified cellulose-based polysurfactant prepared in Example 1 into 70 g of water, and mix evenly to obtain an emulsified viscosity reducer.

Embodiment 3

[0065] Embodiment 3 prepares modified cellulose-based polysurfactant

[0066] Proceed as follows:

[0067] Step (1) Weigh 15g of vinyltrimethylsilane and disperse it in a mixture of 100g of ethanol and water, wherein the mass ratio of ethanol to water is 9:1, add citric acid to adjust the pH value of the system to 5, and stir at room temperature 0.8h, so that the modifier is dispersed evenly;

[0068] Step (2) Weigh 8g of hydroxypropyl methylcellulose with a particle size of 200nm and add it to the dispersion prepared in step (1), stir and react rapidly at 60°C for 1h to obtain a double bond modified cellulose solution ;

[0069] Step (3) filtering and washing the mixed solution in step (2), drying the filter cake to obtain double bond modified cellulose powder;

[0070] Step (4) Weigh 8 g of double bond modified cellulose powder prepared in step (3) and disperse in 100 g of water.

[0071] Step (5) Weigh 25g of sodium 2-acrylamido-2-methylpropanesulfonate and add it to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity average molecular weight | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com