Method for screening high-yield strain of biological dust suppressant

A technology for high-yield strains and dust suppressants, applied in biochemical equipment and methods, measurement/inspection of microorganisms, separation of microorganisms, etc., can solve the problem that strains have a greater impact on the yield of biological dust suppressants, and it is difficult for strains to efficiently produce dust suppressants , Low output of biological dust suppressant, etc., to achieve the effect of protecting its own performance, avoiding mutation and bacterial contamination, and ensuring excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

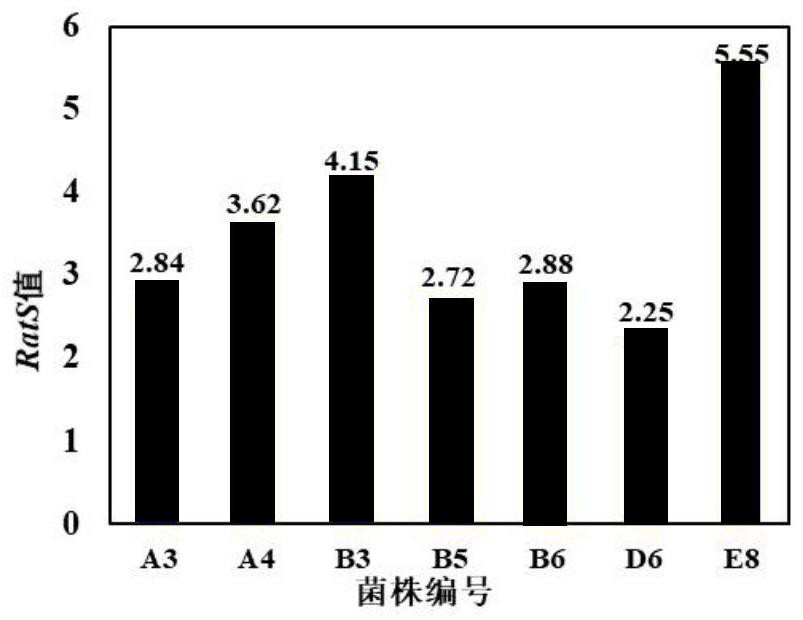

[0020] Implementation case: Screening high-yielding strains of biological dust suppressants

[0021] First, a medium for activating and expanding the cultured strain is prepared. Preparation of liquid activation medium: Weigh 3.00 g of beef extract, 10.00 g of peptone, and 10.00 g of sodium chloride, add sterile water to make up to 1 L, adjust pH to 7.00, and divide into 2100 ml conical flasks, each containing 100 ml of liquid, Sterilize at 121°C for 15min and cool to room temperature; prepare solid-state activation medium: weigh 3.00g of beef extract, 10.00g of peptone, 10.00g of sodium chloride, and 15g of agar, add sterile water to make up to 1L, and adjust pH To 7.00, sterilize at 121°C for 15min, then cool to 50°C, take out 15ml of the medium and inject it into a blank petri dish, and solidify into a solid after cooling for 10min; prepare growth medium: yeast powder 5.00g, pancreas Peptone 10.00g, sodium chloride 10.00g, add sterile water to make the volume to 1L, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com