Process for recovering uranium in water through photocatalytic reduction immobilization-electrooxidation enrichment-precipitation separation

A technology of precipitation separation and photocatalysis, applied in electrolysis process, electrolysis components, cells, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

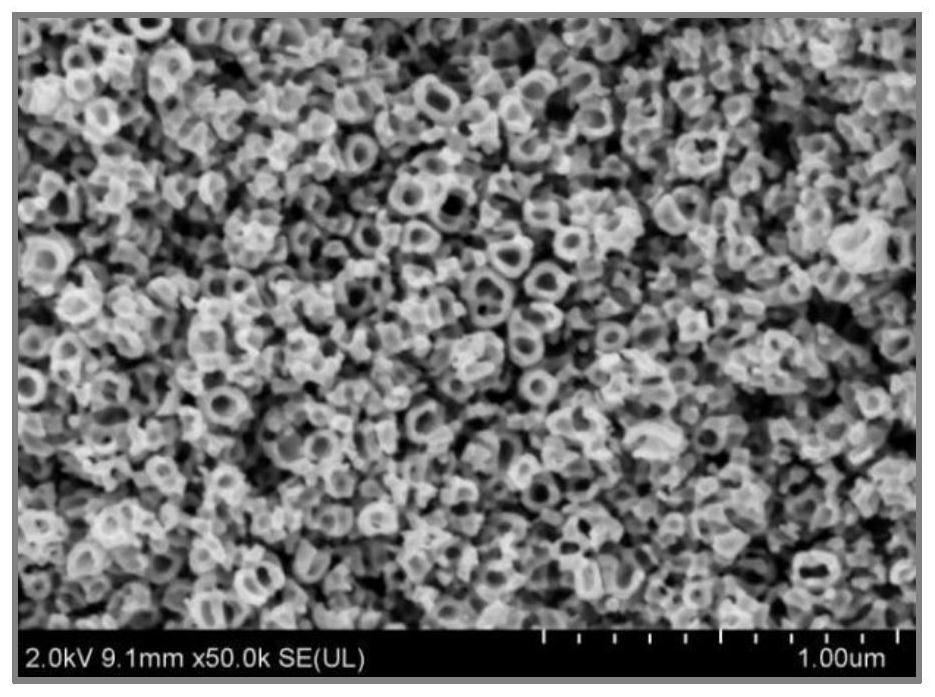

[0049] The preparation method of titanium dioxide nano-array of the present invention is as follows:

[0050] The titanium sheet is used as the anode and the inert material is used as the cathode for electrochemical oxidation. The optimum oxidation voltage is 15-20V to obtain the titanium sheet with the titanium dioxide oxide layer on the surface; annealing the titanium sheet with the titanium dioxide oxide layer on the surface is the best. The annealing temperature is 600-750° C., and then ultrasonic cleaning and drying are performed in deionized water to obtain titanium dioxide nano-arrays.

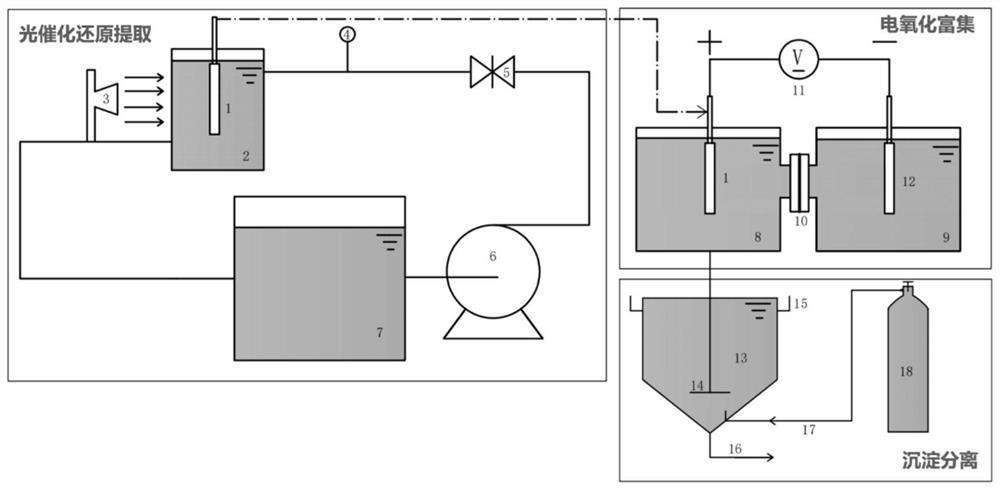

[0051] The invention provides a process of photocatalytic reduction fixation-electrooxidation enrichment-precipitation separation co-production of high-efficiency adsorption reduction, electrooxidation enrichment, precipitation separation and recovery of uranium, including the following three steps:

[0052] Step 1, photocatalytic reduction and fixation of uranium: the photocatalyst gen...

Embodiment 1

[0057] Laboratory simulation: the uranium-containing waste water is drawn from the uranium waste liquid pool 7 by the water pump 6 (the initial concentration of the uranium waste liquid is 0.05mmol / L, pH=5.2), and enters the photocatalytic reactor 2. The catalytic reactor is made of quartz glass, and a fixed photocatalyst 1 (3cm*3cm) is arranged in the photocatalytic reactor. see photos figure 2 , SEM characterization results see image 3 , X-ray diffraction characterization results see Figure 4 ), under the condition of irradiation by the ultraviolet light source 3, photogenerated electrons are generated, and the photogenerated electrons reduce uranium (VI) in water to uranium (IV), and deposit the reduced uranium (IV) on the surface of the titanium dioxide nano-array. The titania nano-array deposited with uranium is moved to the anode chamber 8 of the double-chamber reactor, the double-chamber reactor is made of quartz glass, the electrolyte of the double-chamber reactor...

Embodiment 2

[0060] The uranium-containing waste water is extracted from the uranium waste liquid pool 7 by the water pump 6 (the initial concentration of the uranium waste liquid is 0.05mmol / L, pH=5.2), and enters the photocatalytic reactor 2. The photocatalytic reactor adopts Made of acrylic, the photocatalytic reactor is equipped with a fixed photocatalyst 1 (3cm*3cm), the fixed photocatalyst 1 is a titanium dioxide nano-array (anodized voltage 15V, annealed at 750°C), under the condition of ultraviolet light source 3 irradiation , generating photo-generated electrons, which reduce uranium (VI) to uranium (IV) in water, and deposit the reduced uranium (IV) on the surface of titanium dioxide nano-arrays. The titania nano-array deposited with uranium is moved to the anode chamber 8 of the double-chamber reactor, the double-chamber reactor is made of quartz glass, the electrolyte of the double-chamber reactor is 0.1mol / L sulfuric acid solution, and the cathode 12 of the double-chamber react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com