Soft magnetic powder, magnetic core, and electronic component

An electronic component and soft magnetic technology, which is applied in the direction of transformer/inductance parts, electrical components, and the magnetism of inorganic materials, and can solve problems such as low heat resistance and insulation resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

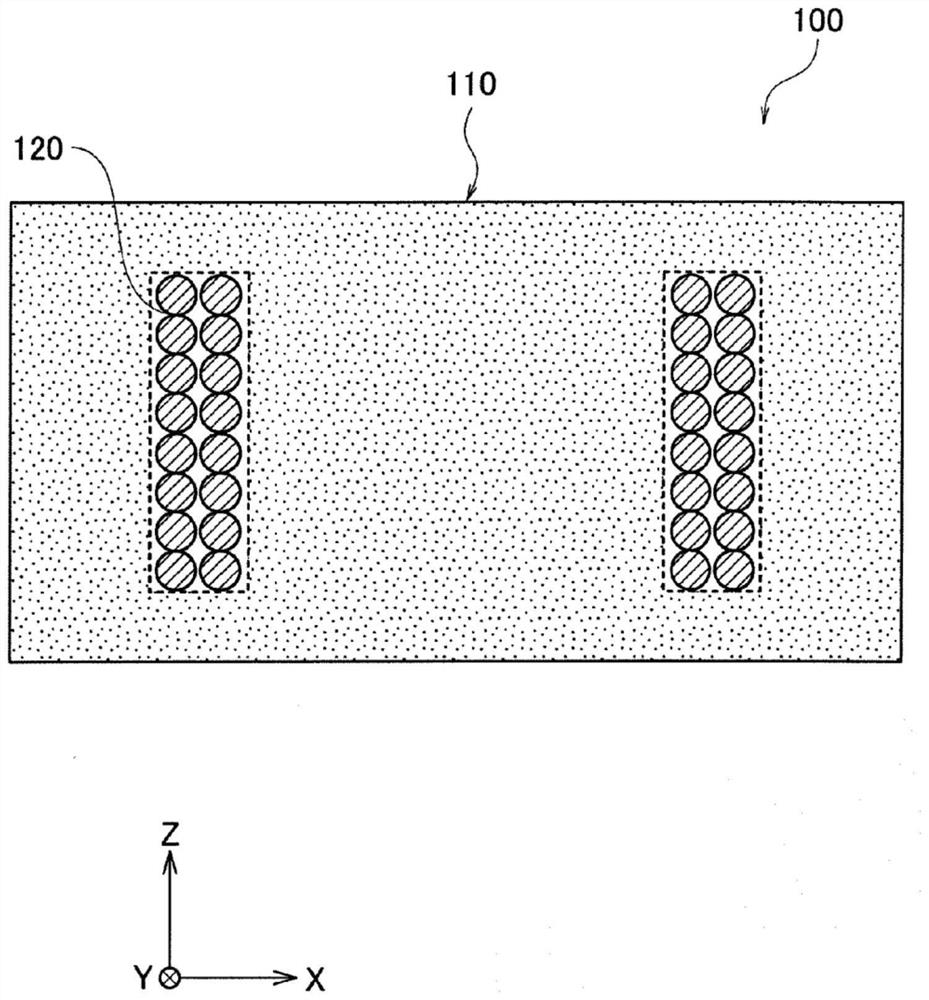

[0033] like figure 1 As shown, the inductor element 100 according to one embodiment of the present invention is composed of a coil 120 and a powder magnetic core 110 , and has a structure in which the coil 120 is embedded in the powder magnetic core 110 .

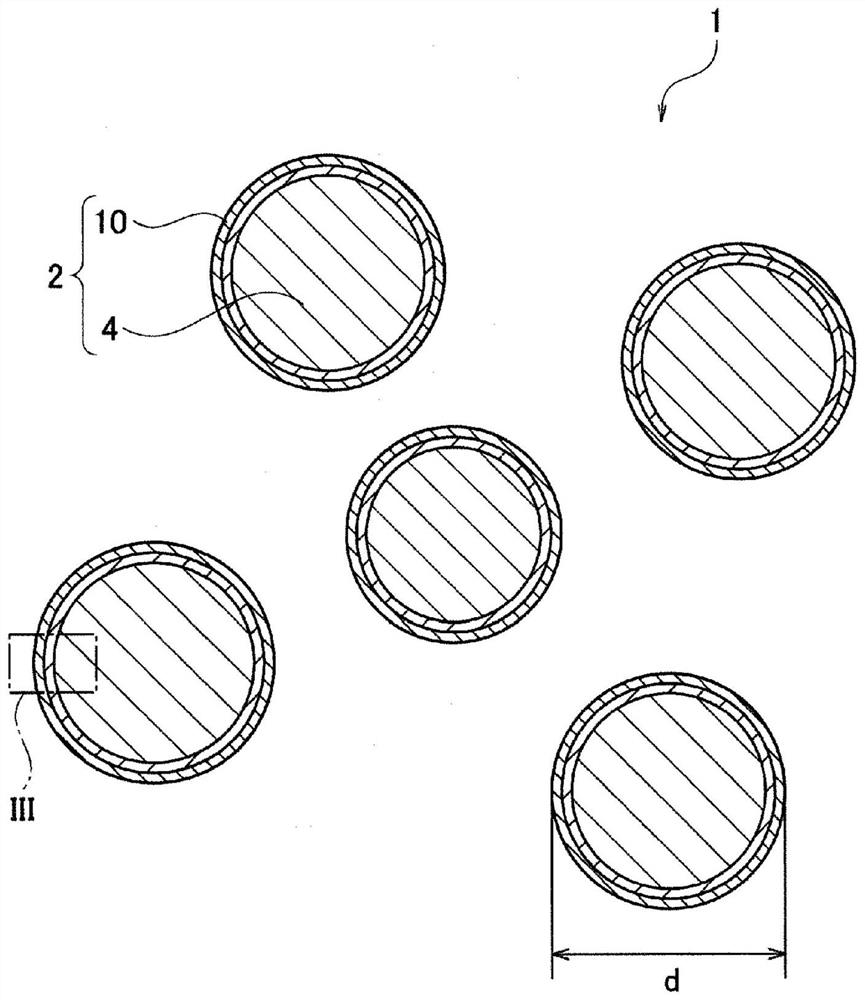

[0034] figure 1 The shape of the powder magnetic core 110 shown is arbitrary and is not particularly limited, and examples thereof include cylindrical, elliptical cylindrical, and prismatic shapes. Furthermore, the powder magnetic core 110 includes soft magnetic powder 1 and resin as a binder, and constitutes figure 2 In the soft magnetic powder 1 shown, a plurality of soft magnetic metal particles 4 are bonded via a resin, thereby being molded into a predetermined shape. Hereinafter, the characteristics of the soft magnetic powder 1 of the present embodiment will be described.

[0035] (soft magnetic powder)

[0036] like figure 2 As shown, the soft magnetic powder 1 of this embodiment includes a plurality of coated...

no. 2 approach

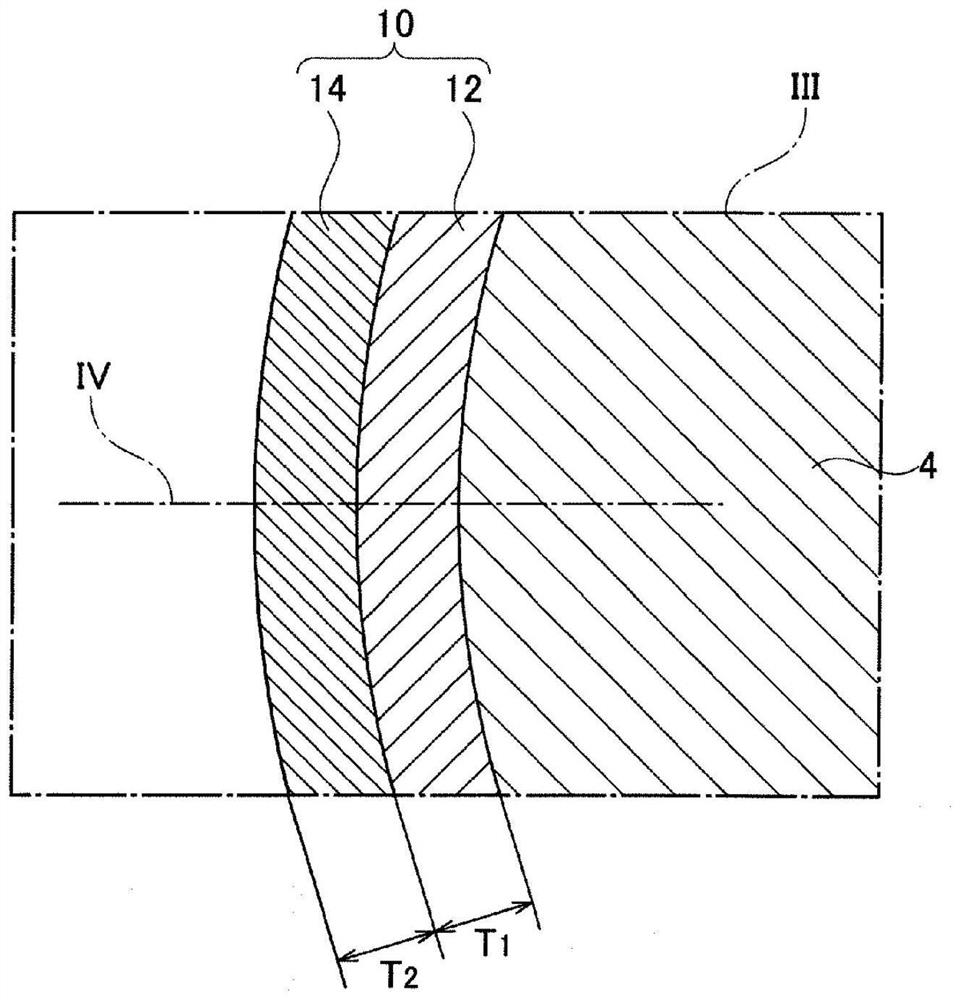

[0082] In the second embodiment, based on Figure 5 and Figure 6 , the case where the intermediate layer 16 exists in the inorganic insulating film 10 will be described. Note that descriptions of the same configurations in the second embodiment as those in the first embodiment are omitted, and the same reference numerals are used.

[0083] The soft magnetic powder 1 of the second embodiment includes the coated particles 2 in which the inorganic insulating coating 10 is formed on the surface of the soft magnetic metal particles 4 as in the first embodiment. Figure 5 It is an enlarged schematic cross-sectional view of the vicinity of the surface of the coated particle 2 in the second embodiment. like Figure 5 As shown, the inorganic insulating film 10 has the first covering part 12 and the second covering part 14 described in the first embodiment, and is divided into at least two layers. Furthermore, in the second embodiment, the intermediate layer 16 is formed between th...

no. 3 approach

[0098] Below, based on Figure 7 A third embodiment of the present invention will be described. Note that descriptions of the same configurations in the third embodiment as those in the first and second embodiments are omitted, and the same reference numerals are used.

[0099] Figure 7 It is a schematic cross-sectional view partially enlarged showing the fine structure of the powder magnetic core 111 of the third embodiment. like Figure 7 As shown, in the third embodiment, soft magnetic powder 8 is also fixed by resin 20 as a binder. Among them, in the third embodiment, the soft magnetic powder 8 is composed of a plurality of powders having different particle size distributions. Specifically, soft magnetic powder 8 includes large-diameter powder 6 having a relatively large particle diameter and small-diameter powder 1a having a relatively small particle diameter.

[0100] The particle size distribution of the large-diameter powder 6 is preferably within the range of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com