Catalyst for organic sulfur hydrolysis and preparation method thereof

A catalyst, organic sulfur technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable wide application, high catalyst cost, and difficulty in sulfation, and achieve easy scale. The effect of popularization and utilization, improving the hydrolysis rate of organic sulfur, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

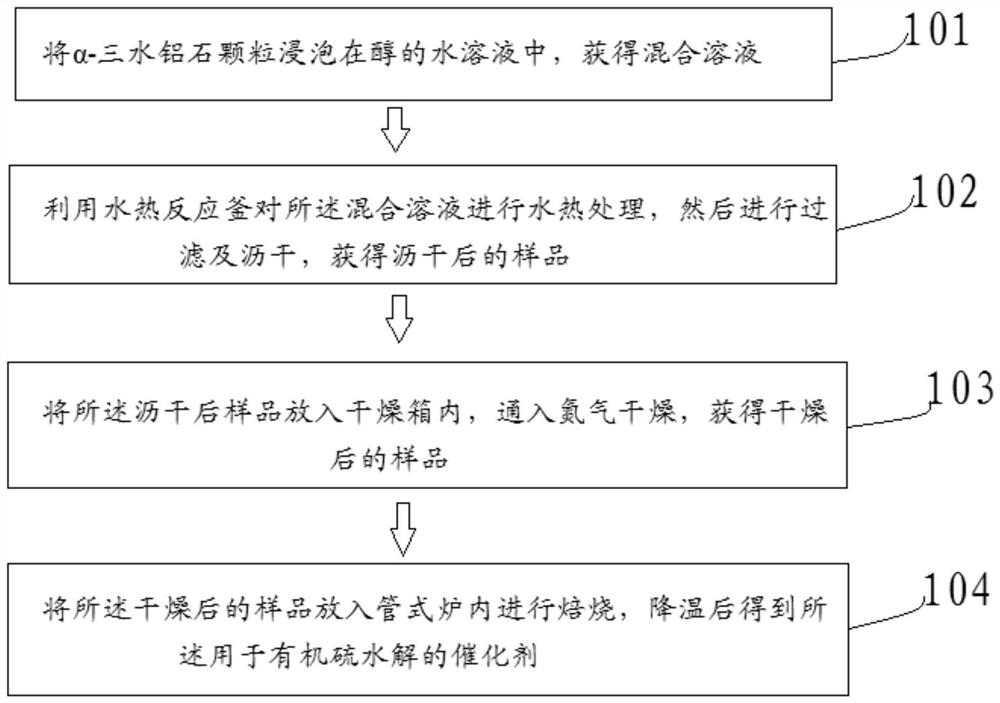

[0027] In view of the above technical problems, the embodiment of the present invention provides a method for preparing a catalyst for the hydrolysis of organic sulfur, as shown in the attached figure 1 Shown, this preparation method comprises the following steps:

[0028] Step 101, immersing α-gibbsite particles in an aqueous alcohol solution to obtain a mixed solution.

[0029] Step 102, using a hydrothermal reactor to perform hydrothermal treatment on the mixed solution, and then filter and drain to obtain a drained sample.

[0030] Step 103, put the drained sample into a drying oven, blow in nitrogen gas to dry, and obtain a dried sample.

[0031] Step 104, put the dried sample into a tube furnace for roasting, and obtain a catalyst for hydrolysis of organic sulfur after cooling down.

[0032] The preparation method of the catalyst provided by the embodiments of the present invention can be used to prepare χ-Al 2 o 3 , wherein the α-gibbsite particles are used as the r...

Embodiment 1

[0070] This embodiment provides a χ-Al 2 o 3 Catalyst and preparation method thereof, specifically, the χ-Al 2 o 3 The catalyst is prepared by the following steps:

[0071] Step 1. Soak the α-gibbsite particles in an aqueous alcohol solution to obtain a mixed solution. Wherein, the alcohol is selected from methanol with a mass concentration of 95%; the ratio of the volume of the aqueous solution of alcohol to the bulk volume of the α-gibbsite particles is 1:1 (both 200 milliliters); the α-gibbsite particles The immersion time in the aqueous alcohol solution was 10 hours.

[0072] Step 2, using a hydrothermal reactor to perform hydrothermal treatment on the mixed solution, and then filtering and draining to obtain a drained sample.

[0073] Wherein, the temperature of the hydrothermal treatment is 100° C., and the time of the hydrothermal treatment is 24 hours.

[0074] Step 3, put the drained sample into a drying box, and pass through nitrogen to dry to obtain a dried sa...

Embodiment 2

[0080] This embodiment provides a χ-Al 2 o 3 Catalyst and preparation method thereof, specifically, the χ-Al 2 o 3 The catalyst is prepared by the following steps:

[0081] Step 1. Soak the α-gibbsite particles in an aqueous alcohol solution to obtain a mixed solution. Wherein, the alcohol is selected from ethanol with a mass concentration of 80%; the ratio of the volume of the aqueous solution of alcohol to the bulk volume of the α-gibbsite particles is 2:1 (400 milliliters and 200 milliliters respectively); The immersion time of the albite particles in the aqueous alcohol solution is 5 hours.

[0082] Step 2, using a hydrothermal reactor to perform hydrothermal treatment on the mixed solution, and then filtering and draining to obtain a drained sample.

[0083] Wherein, the temperature of the hydrothermal treatment is 200° C., and the time of the hydrothermal treatment is 10 hours.

[0084] Step 3, put the drained sample into a drying box, and pass through nitrogen to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com