Preparation method of phenyl alkoxy silane

A technology of phenylalkoxysilane and alkoxysilane, which is applied in the field of preparation of phenylalkoxysilane, can solve the problems of danger and strict raw material requirements, achieve mild reaction conditions and reduce the number of rectification steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

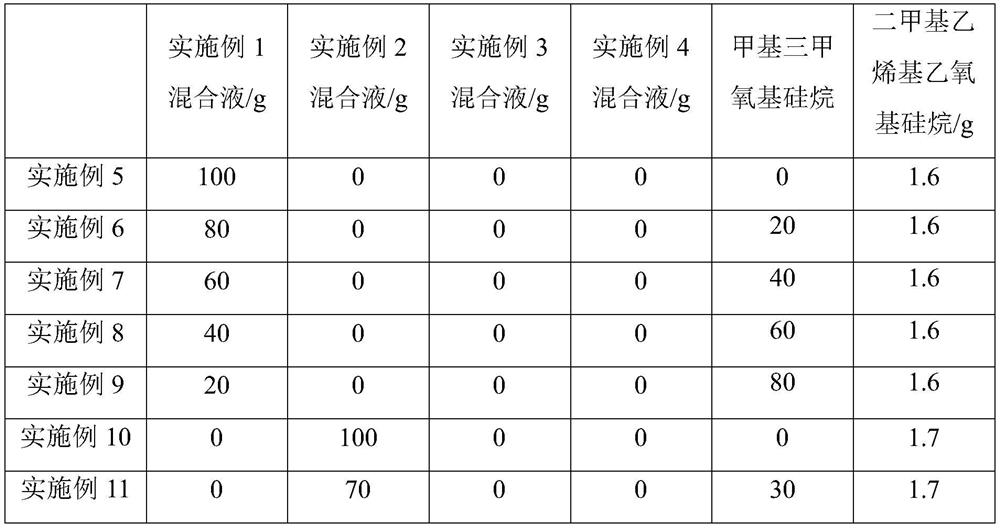

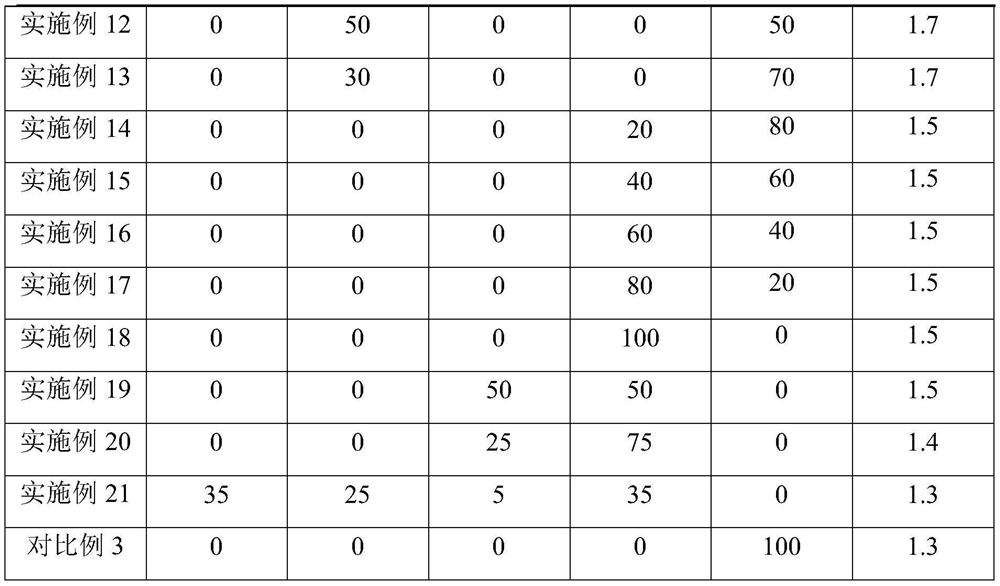

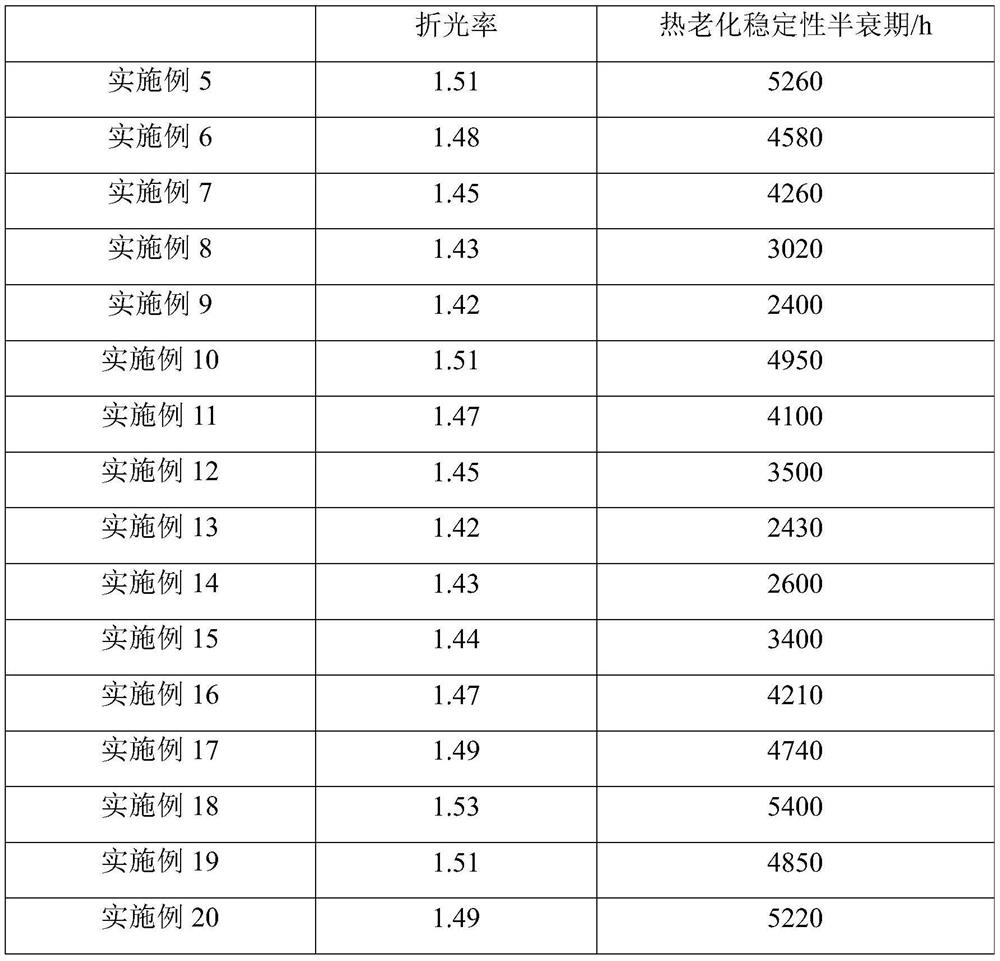

Examples

Embodiment 1

[0019] Add 400g of methyltrimethoxysilane and 1.1mol of sodium methoxide into the reaction kettle, pass through nitrogen protection, stir evenly, and maintain the temperature at 20°C, and then add 1.2mol of chlorobenzene and dimethyltetramethoxydimethoxide dropwise at the same time Silane 1mol. Add dropwise for 2h and continue the reaction for 6h. The reaction liquid after the reaction is first filtered, and the filtrate is separated by rectification to separate methylphenyldimethoxysilane and methyltrimethoxysilane. The yield of methylphenyldimethoxysilane is 45.6%, and the yield of methyltrimethoxysilane is 95.7%.

Embodiment 2

[0021] Add 250 g of tetraethyl silicate and 1.2 mol of sodium ethoxide into the reaction kettle, pass through helium protection, stir evenly, and maintain the temperature at 35 ° C, and then add 1 mol of chlorobenzene and 1 mol of hexaethoxydisilane dropwise at the same time. Add dropwise for 3h and continue the reaction for 5h. The reaction liquid after the reaction is first filtered, and the filtrate is separated by rectification to separate phenyltriethoxysilane and tetraethyl silicate. The yield of phenyltriethoxysilane is 40.6%, and the yield of tetraethyl silicate is 93.4%.

Embodiment 3

[0023] Add 300 g of dimethyldimethoxysilane and 1 mol of potassium methylate into the reaction kettle, pass through nitrogen protection, stir evenly, and maintain the temperature at 50 ° C, and then add 1.1 mol of bromobenzene and tetramethyldimethoxy Disilane 1mol. Add dropwise for 4h and continue the reaction for 4h. The reaction liquid after the reaction is first filtered, and the filtrate is separated by rectification to separate dimethylphenylmethoxysilane and dimethyldimethoxysilane. The yield of dimethylphenylmethoxysilane is 60.7%, and the yield of dimethyldimethoxysilane is 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com