Separation method of resin/pigment in color photoresist stripping waste liquid

A technology for stripping waste liquid and color photoresist, applied in separation methods, chemical instruments and methods, organic dyes, etc., can solve the problems of non-conformity with the development concept of carbon reduction, high disposal costs, waste of resources, etc., to reduce impact, reduce Yields, the effect of simplifying separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

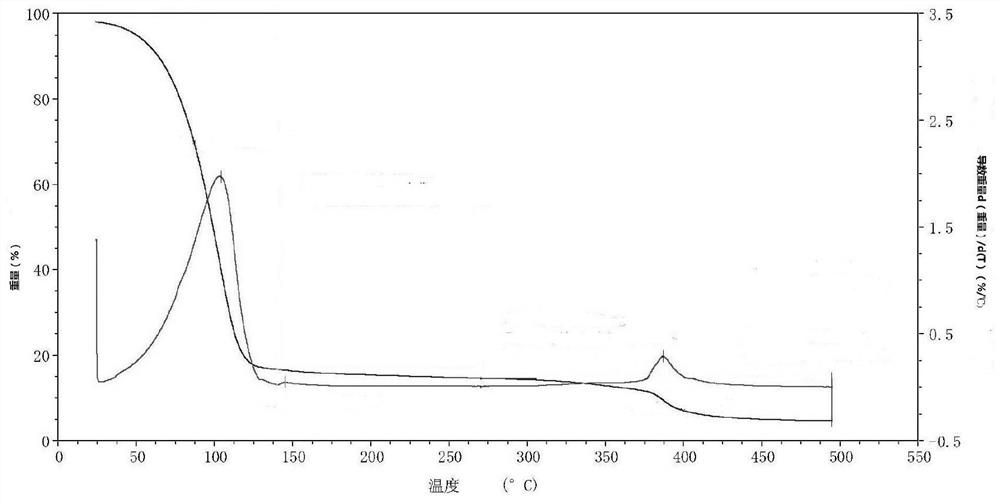

[0031] (1) Green stripping waste liquid, carry out thermogravimetric analysis (TGA), analysis result sees figure 1 , Two peaks appeared at 104.2°C and 386.83°C respectively, the weight loss below 140°C was 81.474%, the weight loss was 2.066% at 140°C to 270°C, and the residual amount at 270°C to 500°C was 9.962%. Through thermogravimetric analysis, it can be known that the components include low molecular volatile organic compounds, higher molecular resins / pigments, etc.

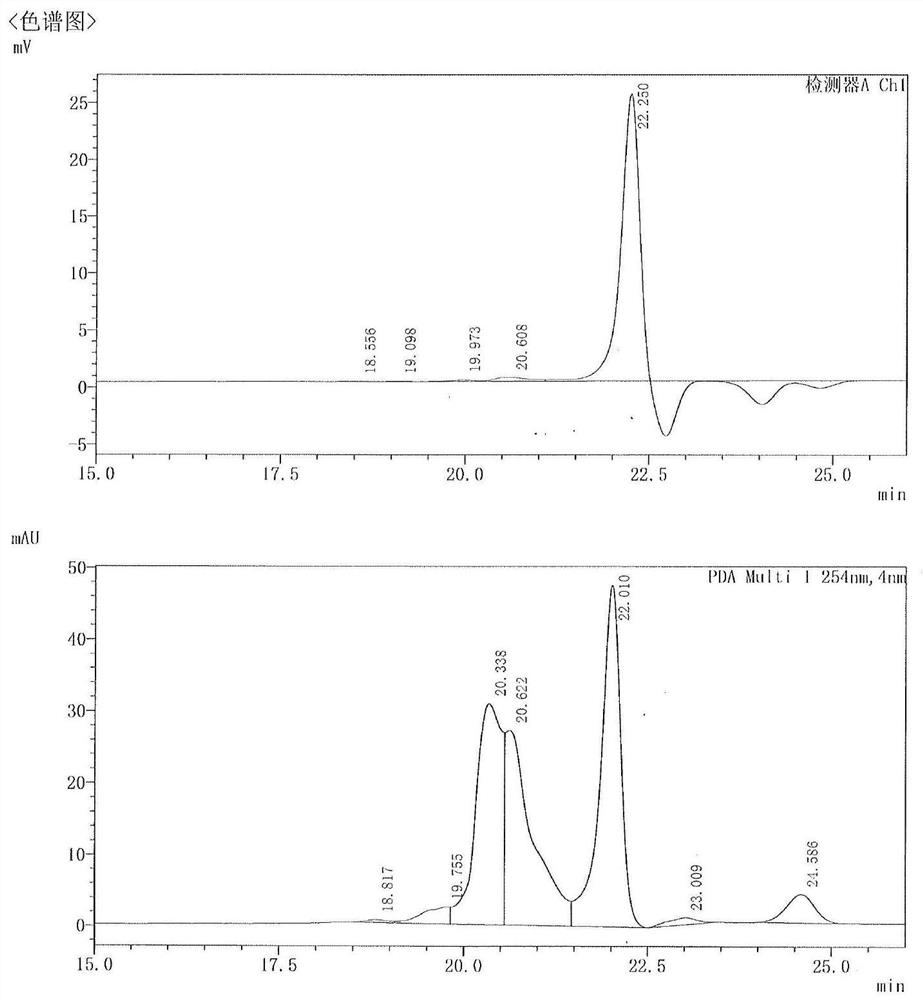

[0032] (2) green stripping waste liquid, carry out chromatographic analysis (GPC), see figure 2 ; The molecular weight distribution appears in three peaks of 105, 314, and 900, mainly low-molecular substances.

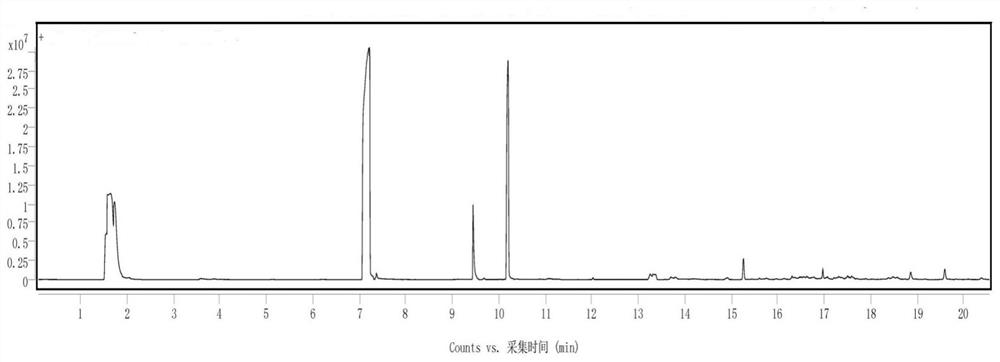

[0033] (3) Green stripping waste liquid, carry out gas-mass analysis (GC-MS), see image 3 , the main substances retrieved are acetaldehyde o-methyl oxime (CAS 33581-43-0), ethylene glycol monoethyl ether (CAS 110-80-5), diethylene glycol diethyl ether (CAS 112-36-7), propylene glycol Methyl ethe...

Embodiment 2

[0042] (1) 1L of green stripping waste liquid is evaporated, the evaporation temperature is 80-120°C, the steam is cooled by cooling water, and about 0.8L of organic solution is collected as the product; when the volume of the solution is reduced to 20%, the evaporation is stopped, and the remaining about 0.2L is evaporated residual liquid.

[0043] (2) Pour the evaporated residue in step (1) into a reaction flask, add about 0.2L of water, the total volume is about 0.4L, a green viscous solid forms, and the solution becomes clear to obtain a solid-containing mixed solution.

[0044] (3) Separating the solid-containing mixed liquid in step (2) through a centrifuge to obtain resin / pigment solids and aqueous organic matter.

[0045] (4) Place the resin / pigment solid in step (3) in an oven and dry it at 150°C, the green solid is about 0.1kg.

[0046] (5) The organic solvent in the step (1) is used as the thinner of the paint, and the aqueous organic matter in the step (3) is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com