Water-based ink, preparation method thereof and plate

A water-based ink, water-based acrylic technology, applied in inks, household appliances, applications, etc., can solve the problems of chemical resistance, aging resistance, water boiling resistance, etc., and achieve good recoating performance, low surface tension, and easy preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

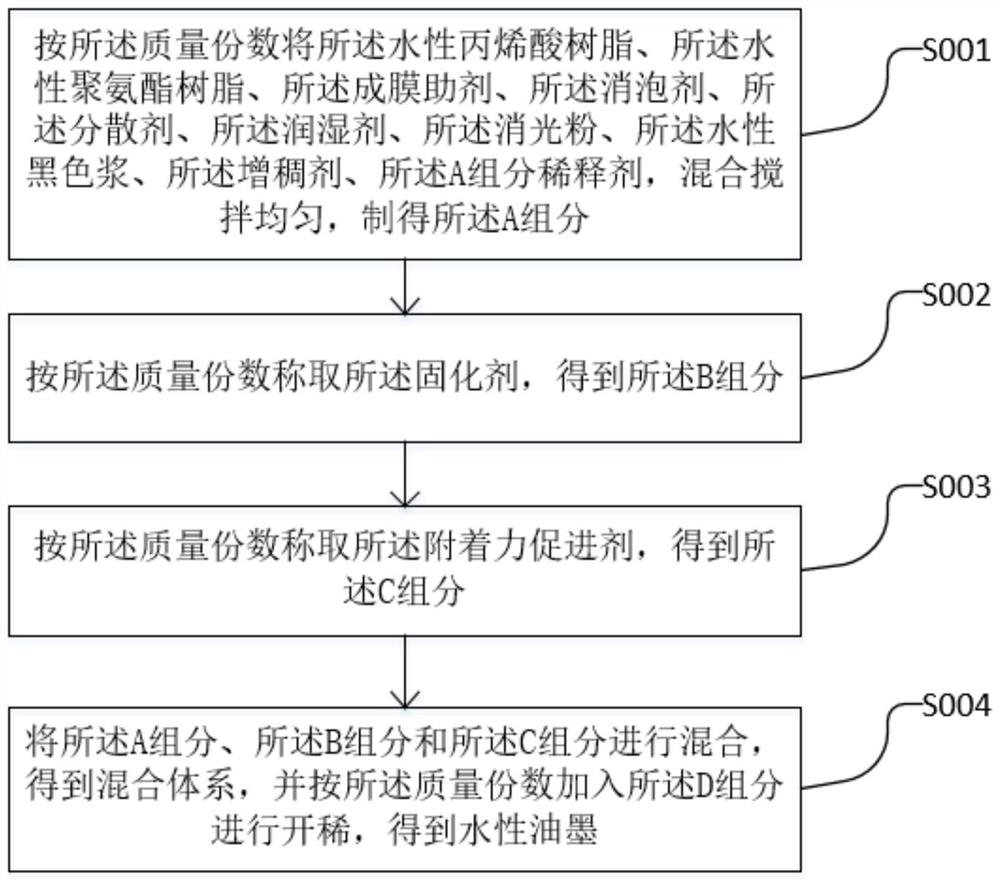

[0039] like figure 1 Shown, a kind of preparation method that an embodiment of the present invention discloses prepares the aforementioned water-based ink, for example, comprises the steps:

[0040] S001: Mix and stir water-based acrylic resin, water-based polyurethane resin, film-forming aid, defoamer, dispersant, wetting agent, matting powder, water-based black slurry, thickener, and component A diluent in parts by mass Evenly, A component is obtained;

[0041] S002: Weigh the curing agent in parts by mass to obtain component B;

[0042] S003: Weigh the adhesion promoter in parts by mass to obtain component C;

[0043] S004: Mix component A, component B and component C to obtain a mixed system, and add component D according to the stated parts by mass for diluting to obtain a mixed solution;

[0044] Further, the mentioned ratio of diluting is 100: (5-15): (1-5): (0-25) for component A: component B: component C: component D.

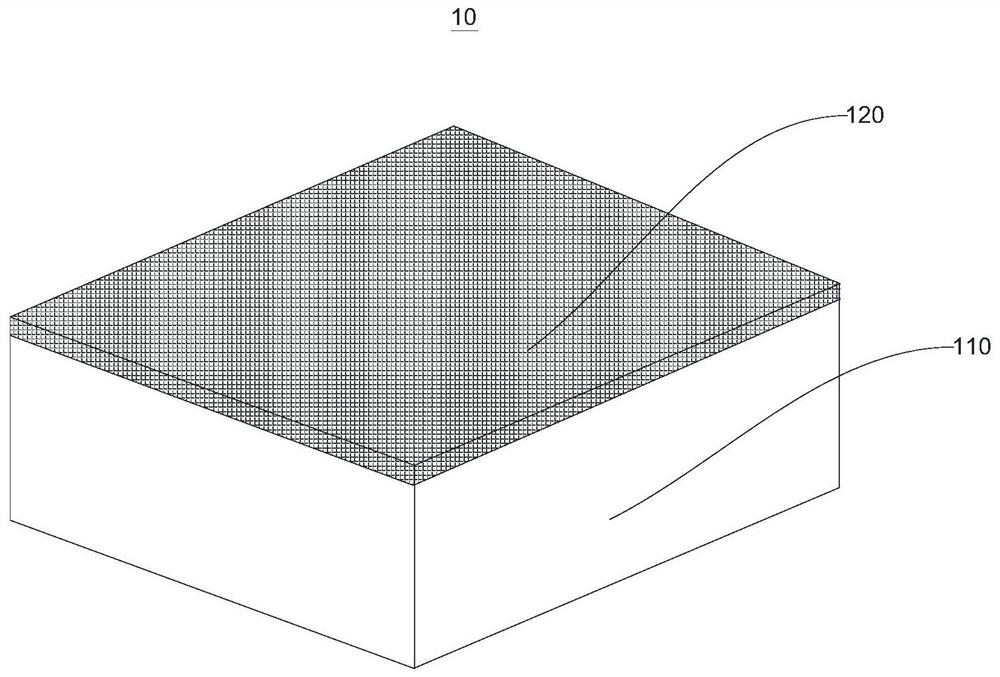

[0045] like figure 2 As shown, one embodim...

no. 1 example

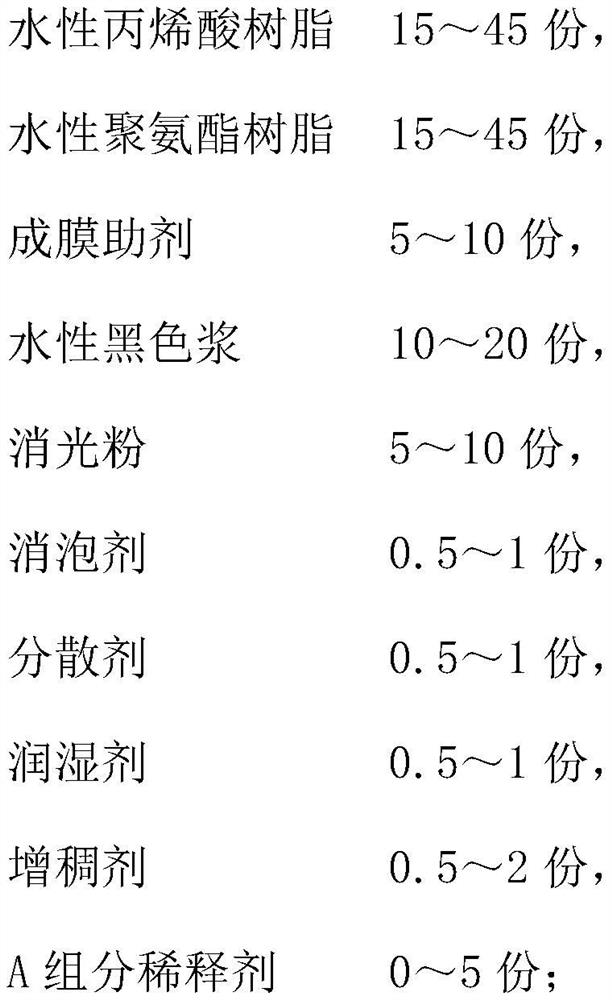

[0050] The water-based ink of the present embodiment weighs ingredients according to the following components and parts by mass thereof:

[0051] Component A: 15 parts of water-based acrylic resin, 45 parts of water-based polyurethane resin, 8 parts of film-forming aid, 20 parts of water-based black paste, 6 parts of matting powder, 0.5 parts of defoamer, 1 part of dispersant, and 1 part of wetting agent , Thickener 0.5 parts, A component thinner 3 parts.

[0052] Component B: 15 parts of curing agent.

[0053] Component C: 2 parts of adhesion promoter.

[0054] Component D: 25 parts of mixed component diluent.

[0055] Specifically, in component A, the water-based acrylic resin is water-based hydroxyacrylic emulsion, the water-based polyurethane resin is water-based fluorine-modified polyurethane emulsion, the film-forming aid is dipropylene glycol dimethyl ether, and the water-based black pulp is high-temperature-resistant boiled water. Dispersible black paste, matting po...

no. 2 example

[0069] The selected specific types of the water-based ink of the present embodiment and the preparation method of the water-based ink and the water-based ink coating are the same as those of the first embodiment. The difference is that the water-based ink of the present embodiment has different mass parts of its components from the first embodiment, and the water-based ink disclosed in the present embodiment is weighed according to the following components and parts by mass:

[0070] Component A: 45 parts of water-based acrylic resin, 15 parts of water-based polyurethane resin, 8 parts of film-forming aid, 20 parts of water-based black paste, 6 parts of matting powder, 0.5 parts of defoamer, 1 part of dispersant, and 1 part of wetting agent , Thickener 0.5 parts, A component thinner 3 parts.

[0071] Component B: 15 parts of curing agent.

[0072] Component C: 2 parts of adhesion promoter.

[0073] Component D: 25 parts of mixed component diluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com