Preparation process of fermented malt syrup

A technology of maltose syrup and preparation process, which is applied in the field of preparation of fermented maltose syrup, which can solve the problems of inaccurate enzyme additive dosage and reduce the preparation effect of maltose syrup, so as to improve the image and reputation, improve shopping satisfaction, and improve the overall effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

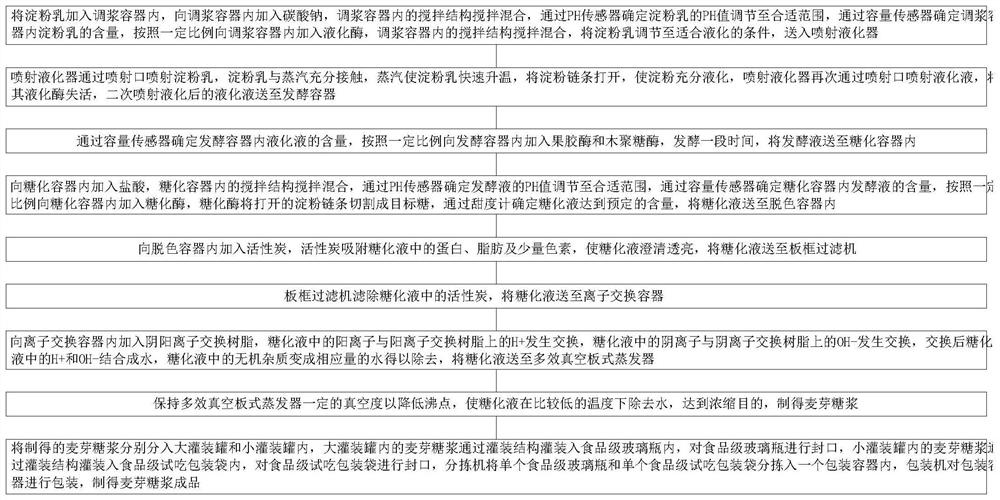

Image

Examples

Embodiment 1

[0028] see figure 1 , the present invention provides the following technical solutions: a preparation process of fermented maltose syrup, comprising the following steps:

[0029] S1: Add starch milk into the pulping container, add sodium carbonate into the pulping container, stir and mix with the stirring structure in the pulping container, adjust the pH value of the starch milk to an appropriate range through the pH sensor, and determine the pulping through the capacity sensor According to the content of starch milk in the container, add liquefaction enzyme into the slurry mixing container according to a certain ratio, stir and mix with the stirring structure in the slurry mixing container, adjust the starch milk to the conditions suitable for liquefaction, and send it to the jet liquefier;

[0030] S2: The jet liquefier sprays the starch milk through the jet port, the starch milk is in full contact with the steam, the steam heats up the starch milk quickly, opens the starch ...

Embodiment 2

[0046] The difference of this embodiment compared with embodiment 1 is:

[0047] Specifically, in step S1, the pH value of the starch milk is 6.0.

[0048] Specifically, in step S1, the addition ratio of starch milk and liquefying enzyme is 12:3.5.

[0049] Specifically, in step S3, the addition ratio of the liquefaction solution, pectinase and xylanase is 15:0.6:0.8.

[0050] Specifically, in step S3, the period of fermentation is 10 hours.

[0051] Specifically, in step S4, the pH value of the fermentation broth is 5.5.

[0052] Specifically, in step S4, the addition ratio of fermentation broth and glucoamylase is 2:0.5.

[0053] Specifically, in step S4, the predetermined content of the saccharified liquid is such that the maltose content reaches ≥ 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com