Converter desilicication and dephosphorization slag and secondary aluminum ash synergistic chromium slag harmlessness process

A technology for secondary aluminum and dephosphorization slag, applied in the direction of improving process efficiency, etc., can solve problems such as no mention of process methods, achieve resource utilization, reduce smelting costs, and improve hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

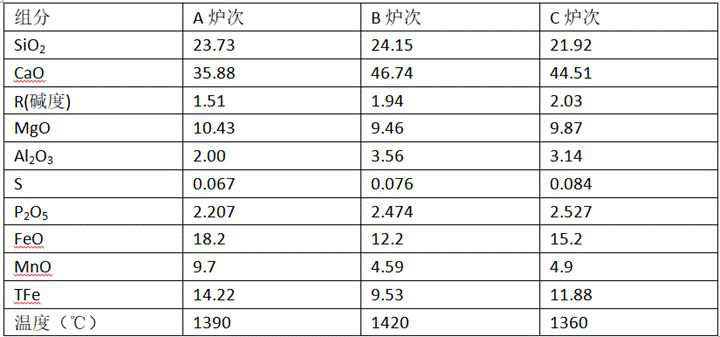

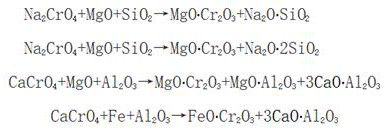

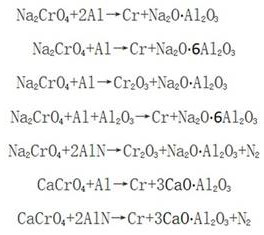

[0027] The implementation of the present invention is illustrated by taking a 150-ton converter production line and taking the slag operation as the main process as an example. A process of converter desiliconization and dephosphorization slag and secondary aluminum ash synergistically harmless chromium slag is implemented according to the following steps :

[0028] 1. Process the chromium slag to 70-200 mesh, and transport it to the high-pressure dry powder pelletizing machine production line for use;

[0029] 2. Crush the secondary aluminum ash to 70 mesh, and transport it to the high-pressure dry powder pelletizing machine production line for use;

[0030] 3. The chromium slag and secondary aluminum ash are produced into pellets with a particle size of 15-30mm on a high-pressure dry powder briquetting machine according to a mass ratio of 6:4, and then transported to the converter production line for use;

[0031] 4. Double slag operation of the converter, while pouring out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com