Modified diaphragm for lithium battery as well as preparation method and application of modified diaphragm

A lithium battery and lithium ion battery technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of reducing the air permeability value of the diaphragm, too large pores, and reducing the tensile strength, so as to improve the electrochemical performance, The preparation method is simple and the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

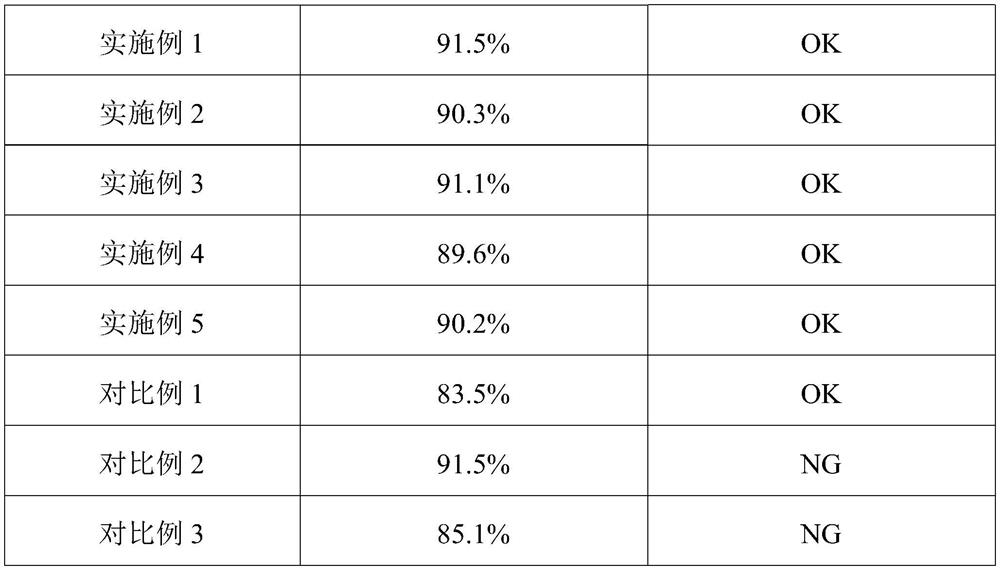

Embodiment 1

[0054] This embodiment provides a separator for a modified lithium battery, the separator for a modified lithium battery includes a substrate and polydopamine on the surface of the substrate, and the substrate includes carboxymethyl cellulose;

[0055] The carboxymethyl cellulose has a length of 500nm and a diameter of 25nm; the porosity of the diaphragm is 70%, and the thickness of the diaphragm is 16 μm; the coating thickness of the polydopamine is 6nm;

[0056] The preparation method of the separator for the modified lithium battery comprises the following steps:

[0057] (1) In the solution containing carboxymethylcellulose, trimethylolmethylamine is added to adjust the pH value of the solution to be 8.5;

[0058] (2) add dopamine in the solution that step (1) obtains, the add-on of described dopamine makes the concentration of dopamine in the solution be 2g / L, and the mass ratio of carboxymethylcellulose and dopamine is 3:1 in the solution, stirs Carrying out the reactio...

Embodiment 2

[0061] This embodiment provides a separator for a modified lithium battery, the separator for a modified lithium battery includes a substrate and polydopamine located on the surface of the substrate, and the substrate includes methyl cellulose;

[0062] The length of the methylcellulose is 600nm, and the diameter is 40nm; the porosity of the diaphragm is 65%, and the thickness of the diaphragm is 10 μm; the coating thickness of the polydopamine is 5nm;

[0063] The preparation method of the separator for the modified lithium battery comprises the following steps:

[0064] (1) In the solution containing methylcellulose, trimethylolmethylamine is added to adjust the pH of the solution to be 8.4;

[0065] (2) add dopamine in the solution that step (1) obtains, the add-on of described dopamine makes the concentration of dopamine in the solution be 1.5g / L, and the mass ratio of methylcellulose and dopamine in the solution is 2:1, stirs Carrying out the reaction for 5 hours to obta...

Embodiment 3

[0068] This embodiment provides a diaphragm for a modified lithium battery, the diaphragm for a modified lithium battery includes a matrix and polydopamine on the surface of the matrix, and the matrix includes hydroxypropyl cellulose;

[0069] The length of the hydroxypropyl cellulose is 300nm, and the diameter is 20nm; the porosity of the diaphragm is 75%, and the thickness of the diaphragm is 18 μm; the coating thickness of the polydopamine is 8nm;

[0070] The preparation method of the separator for the modified lithium battery comprises the following steps:

[0071] (1) adding trimethylol methylamine to the solution containing hydroxypropyl cellulose to adjust the pH of the solution to be 8.6;

[0072] (2) add dopamine in the solution that step (1) obtains, the add-on of described dopamine makes the concentration of dopamine in the solution be 2.5g / L, and the mass ratio of hydroxypropyl cellulose and dopamine in the solution is 4:1, Stirring and reacting for 8 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com