Eddy micro-mixer based on array type micro heat source and mixing method of eddy micro-mixer

A micro-mixer and array-type technology, applied in the field of optofluidics, can solve problems such as inconvenient capture, fluid mixing limitation, and unstable bubbles, and achieve the effects of short reaction time, avoiding pollution and damage, and simple and easy production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

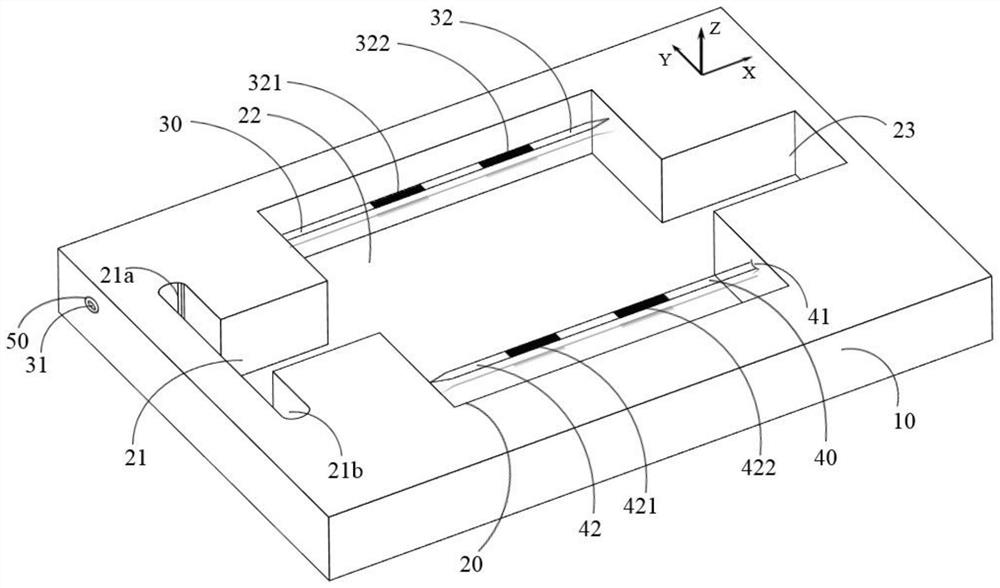

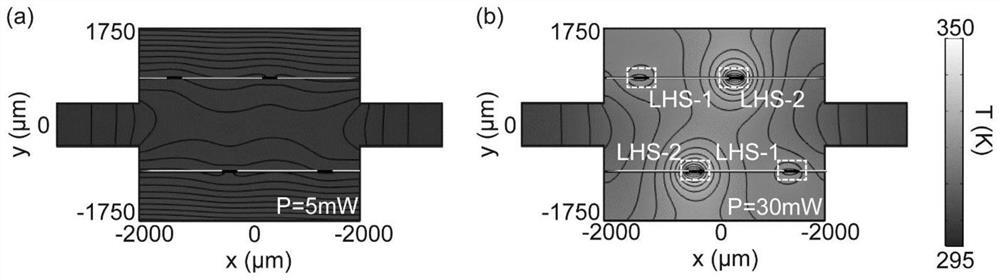

[0049] Such as figure 1 As shown, the vortex micro-mixer based on the arrayed micro heat source according to Embodiment 1 of the present invention includes a substrate 10, a micro flow channel 20, a first array type micro heat source 30 and a second array type micro heat source 40, wherein the micro flow channel 20 Set in the base 10, it includes an input tank 21, a mixing tank 22 and an output tank 23 connected in sequence. The input tank 21 is used to inject at least two different liquids, and the output tank 23 is used to discharge the mixed liquid in the mixing tank 22. The first array type micro heat source 30 and the second array type micro heat source 40 are spaced from each other and can be movably arranged on the substrate 10, each array type micro heat source includes an optical signal input end and an optical signal excitation end, and the optical signal input end is used for When the optical signal of predetermined power is connected, the optical signal excitation ...

Embodiment 2

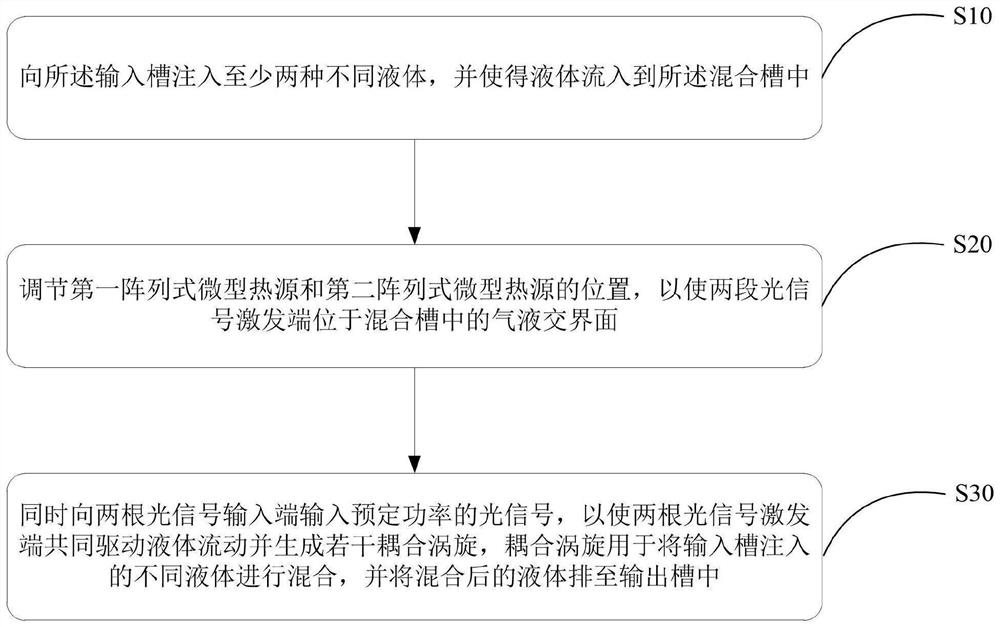

[0059] As shown in the figure, the mixing method of the vortex micro-mixer based on the array micro-heat source provided in the second embodiment includes the following steps:

[0060] Step S10: inject at least two different liquids into the input tank 21, and make the liquids flow into the mixing tank 22;

[0061] Step S20: adjusting the positions of the first array micro heat source 30 and the second array micro heat source 40, so that the excitation ends of the two sections of optical signals are located at the gas-liquid interface in the mixing tank 22;

[0062] Step S30: Simultaneously input optical signals of predetermined power to the two optical signal input terminals, so that the two optical signal excitation terminals jointly drive the liquid flow and generate several coupling vortices, which are used to inject different liquids into the input tank 21 Mixing takes place and the mixed liquid is discharged to output tank 23 .

[0063] Specifically, in step S10 , liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com