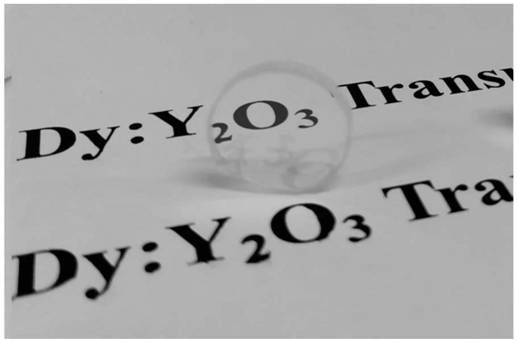

Preparation method of high-transmittance Dy: Y2O3 transparent ceramic

A technology of transparent ceramics and high transmittance, which is applied in the field of solid laser gain medium materials, can solve the problems of unsatisfactory heat dissipation effect of laser gain medium, degradation of laser beam quality, and decrease of laser efficiency, so as to achieve high laser damage threshold and avoid heat loss. Conductivity loss, the effect of inhibiting excessive grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Specifically include the following steps:

[0031] Step 1: preparation of solution;

[0032] Using Dy(NO 3 ) 3 , Y(NO 3 ) 3 , La(NO 3 ) 3 , ZrOCl 2 ·8H 2 O solution as raw material, the four solutions according to the chemical formula (Dy 0.006 Zr 0.01 La 0.005 Y 0.979 ) 2 o 3 Mix and make 5L solution, as the mother liquor, the molar concentration of Y ion in the mother liquor is 0.2mol / L, and the molar ratio of Dy and Y ion is between 1 / 200 and 1 / 50, and the molar ratio of Zr and Y ion is between Between 1 / 200 and 1 / 20, the molar ratio of La and Y ions is between 1 / 200 and 1 / 20; the NH4 OH is diluted with water to NH with a molar concentration of 0.6 mol / L 4 OH aqueous solution is used as a precipitating agent;

[0033] Step 2: preparation of the pre-drive body;

[0034] Using the forward titration method, the precipitant is dripped into the mother liquor at a rate of 10mL / min through a peristaltic pump, and at the same time high-speed stirring is carri...

Embodiment 2

[0046] Specifically include the following steps:

[0047] Step 1: preparation of solution;

[0048] Using Dy(NO 3 ) 3 , Y(NO 3 ) 3 , La(NO 3 ) 3 , ZrOCl 2 ·8H 2 O solution as raw material, the four solutions according to the chemical formula (Dy 0.006 Zr 0.01 La 0.005 Y 0.979 ) 2 o 3 Mix and make 5L solution, as the mother liquor, the molar concentration of Y ion in the mother liquor is 0.1mol / L, and the molar ratio of Dy and Y ion is between 1 / 200 and 1 / 50, and the molar ratio of Zr and Y ion is between Between 1 / 200 and 1 / 20, the molar ratio of La and Y ions is between 1 / 200 and 1 / 20; the NH 4 OH is diluted with water to NH with a molar concentration of 0.5 mol / L 4 OH aqueous solution is used as a precipitating agent;

[0049] Step 2: preparation of the pre-drive body;

[0050] Using the forward titration method, the precipitant is dripped into the mother liquor at a rate of 12mL / min through a peristaltic pump, and at the same time high-speed stirring is car...

Embodiment 3

[0062] Specifically include the following steps:

[0063] Step 1: preparation of solution;

[0064] Using Dy(NO 3 ) 3 , Y(NO 3 ) 3 , La(NO 3 ) 3 , ZrOCl 2 ·8H 2 O solution as raw material, the four solutions according to the chemical formula (Dy 0.006 Zr 0.01 La 0.005 Y 0.979 ) 2 o 3 Mix and make 5L solution, as the mother liquor, the molar concentration of Y ion in the mother liquor is 0.6mol / L, and the molar ratio of Dy and Y ion is between 1 / 200 and 1 / 50, and the molar ratio of Zr and Y ion is between Between 1 / 200 and 1 / 20, the molar ratio of La and Y ions is between 1 / 200 and 1 / 20; the NH 4 OH is diluted with water to NH with a molar concentration of 1.0 mol / L 4 OH aqueous solution is used as a precipitating agent;

[0065] Step 2: preparation of the pre-drive body;

[0066] Using the forward titration method, the precipitating agent is dripped into the mother liquor at a rate of 20mL / min through a peristaltic pump, and high-speed stirring is carried out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com