Method for separating toluene-methanol through extractive distillation

An extractive distillation and extractive distillation tower technology, which is applied in the field of separation of toluene and methanol, can solve problems such as difficulty in finding ionic liquids, and achieve the effects of good separation effect, easy control and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

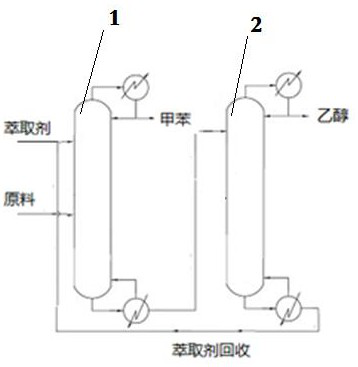

[0019] Embodiment 1: as figure 1 The extractive distillation process shown. The extractive distillation column 1 has 19 theoretical plates, the extractant 1-butyl-2,3-dimethylimidazole acetate enters from the 2nd theoretical plate, and the flow rate is 10kg / h, and the mixture of toluene and ethanol enters from the 9th theoretical plate Block theoretical plate enters, and composition is toluene 82.0wt%, ethanol 18.0wt%, and flow rate is 100kg / h; Extractive distillation column 1 normal pressure operation, reflux ratio 2, the toluene that mass fraction can be obtained at the tower top is 99.5wt%, tower The still discharge is 1-butyl-2,3-dimethylimidazole acetate-methanol mixed solution with a toluene content lower than 0.01 wt%; It is 110Pa, and the theoretical plate of extraction agent recovery tower 2 is 4 pieces, and 99.5wt% methanol is obtained at the top, and 99.0wt% 1-butyl-2,3-dimethylimidazole acetate is obtained at the bottom, which can be recycled.

Embodiment 2

[0020] Embodiment 2: as figure 1 The extractive distillation process shown. The extractive distillation column 1 has 22 theoretical plates, the extractant 1-butyl-2,3-dimethylimidazole acetate enters from the second theoretical plate, and the flow rate is 12kg / h, and the mixture of toluene and methanol enters from the 10th theoretical plate Block theoretical plate enters, and composition is toluene 77.0wt%, methyl alcohol 23.0wt%, and flow rate is 110kg / h; Extractive distillation tower 1 normal pressure operation, reflux ratio 2.5, the toluene that mass fraction can be obtained at the tower top is 99.5wt%, tower The still discharge is 1-butyl-2,3-dimethylimidazole acetate-methanol mixed solution with a toluene content lower than 0.01 wt%; It is 120Pa, and the theoretical plate of extraction agent recovery tower 2 is 6 pieces, 99.5wt% methanol is obtained at the top, and 99.0wt% 1-butyl-2,3-dimethylimidazole acetate is obtained at the bottom, which can be recycled.

Embodiment 3

[0021] Embodiment 3: as figure 1 The extractive distillation process shown. The extractive distillation column 1 has 25 theoretical plates, the extractant 1-butyl-2,3-dimethylimidazole acetate enters from the second theoretical plate, and the flow rate is 15kg / h, and the mixture of toluene and methanol enters from the 11th theoretical plate. Block theoretical plate enters, and composition is toluene 72.0wt%, methyl alcohol 28.0wt%, and flow rate is 130kg / h; Extractive distillation tower 1 normal pressure operation, reflux ratio 3, the toluene that mass fraction can be obtained at the top of the tower is 99.5wt%, tower The still discharge is 1-butyl-2,3-dimethylimidazole acetate-methanol mixed solution with a toluene content lower than 0.01 wt%; 150Pa, the theoretical plate of extractant recovery tower 2 is 6 pieces, 99.5wt% methanol is obtained at the top, and 99.0wt% 1-butyl-2,3-dimethylimidazole acetate is obtained at the bottom, which can be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com