Texture prediction method in thermoplastic large deformation process of near-alpha type titanium alloy

A prediction method, titanium alloy technology, applied in the direction of testing metals, instruments, design optimization/simulation, etc., can solve the problems of not considering the temperature, not taking into account the volume change of the two phases of titanium alloy, and the calculation amount is too large, etc., to achieve the simulation results Reliable, the effect of reducing time cost and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0125] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

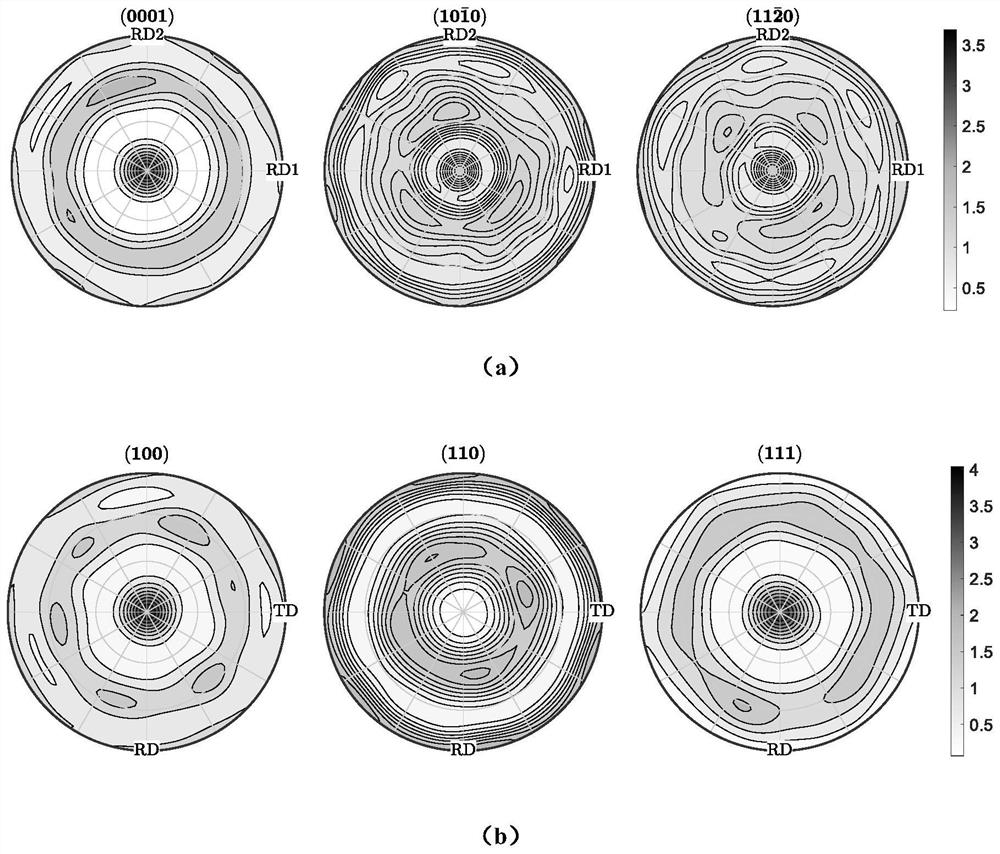

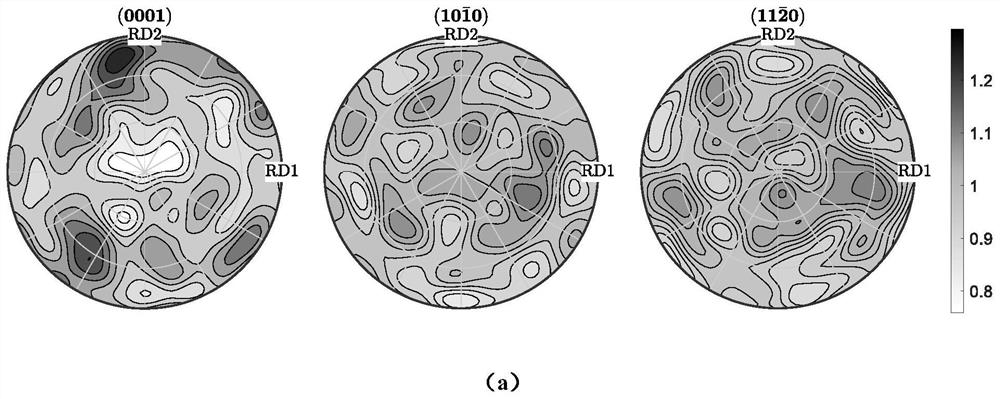

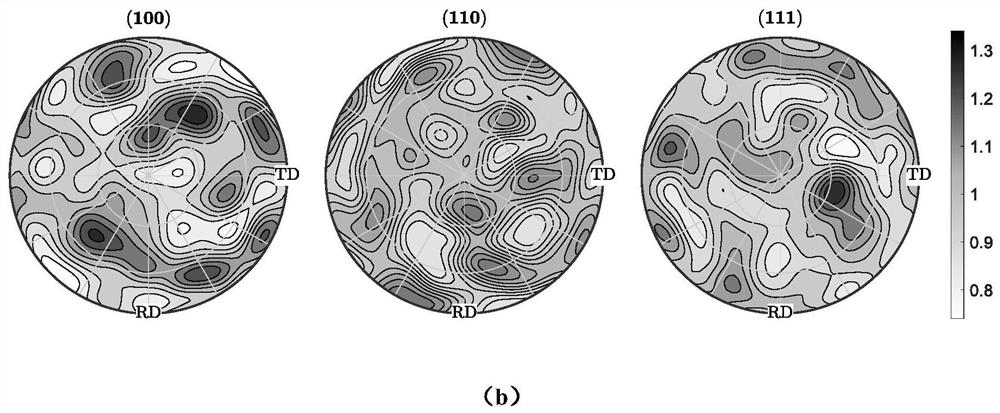

[0126] The invention provides a texture prediction method in the process of large thermoplastic deformation of near-alpha titanium alloy.

[0127] like Figure 11 As shown, the method includes the following steps:

[0128] S1: Use an optical microscope to obtain the metallographic structure pictures of near-α-type titanium alloy materials at different temperatures, and use the digital image processing function of ImageJ software to quantitatively analyze the volume fractions of α and β phases in near-α-type titanium alloys, and use linear interpolation method Obtain the volume fraction of α and β phases in the near-α-type titanium alloy at any temperature in the temperature range;

[0129] S2: Complete the uniaxial isothermal constant strain rate therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com