Margarya melanioides pink oil boiling equipment capable of automatically heating and production process of margarya melanioides pink oil boiling equipment

A production process, pink oil technology, applied in the direction of edible oil/fat, mixer with rotating stirring device, mixer, etc., can solve the problems that the stability of the product process cannot be guaranteed, the heating uniformity is not enough, and it cannot be used. Achieve the effect of reducing manual labor intensity, reducing human errors, and facilitating subsequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

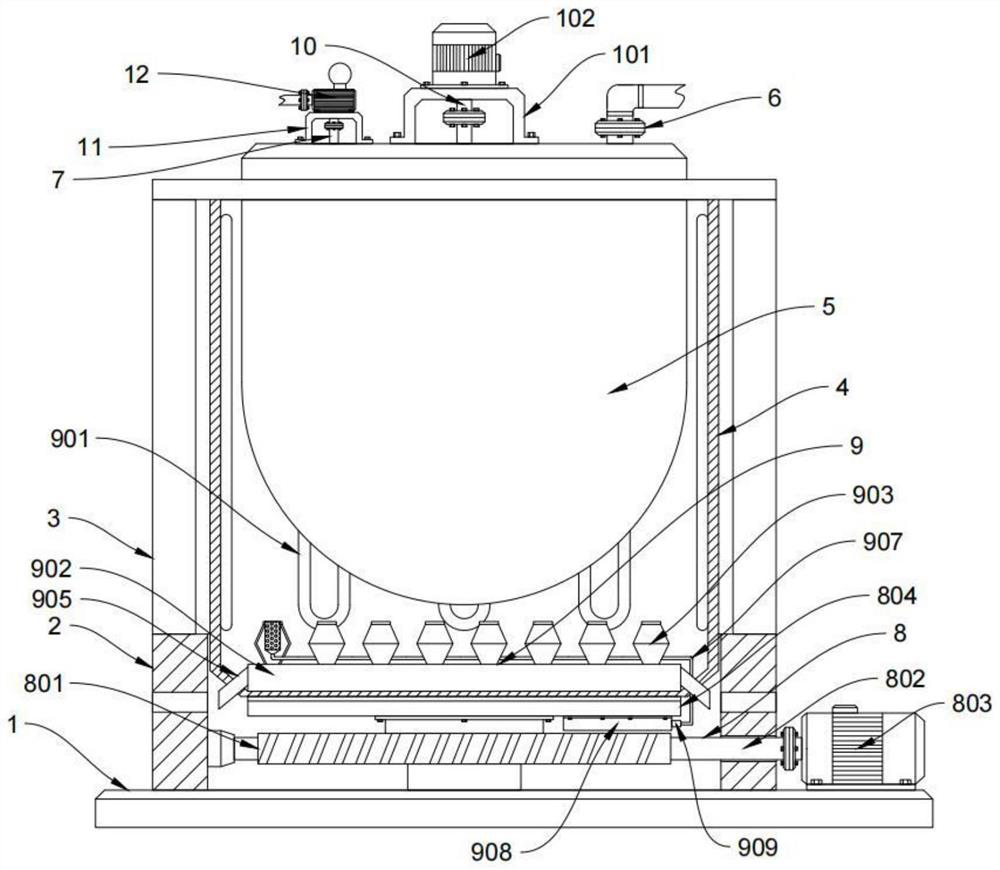

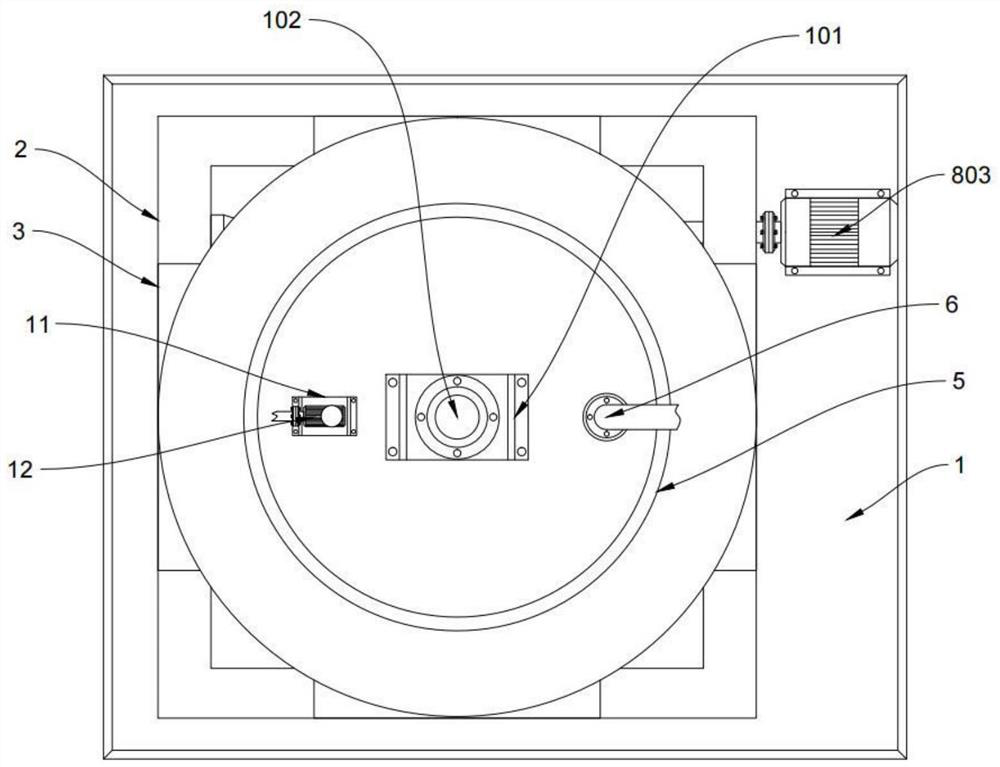

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

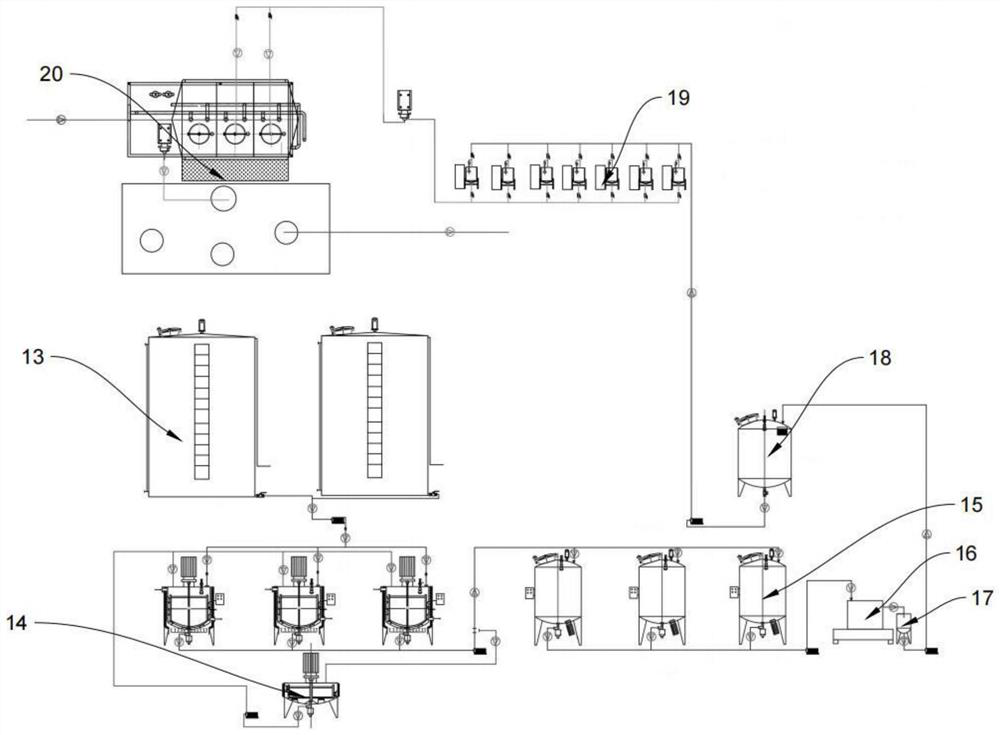

[0031] combined with figure 1 , a production process for boiling snail pink oil that can be automatically heated, the production process includes the following steps:

[0032] Step 1: placing the raw soybean oil in the soybean oil storage tank 13 and filling it up;

[0033] Step 2: Pump the soybean oil from the storage tank into the cooking equipment through the soybean oil discharge pump, and the flow meter monitors the flow rate, and when the amount set by the program is reached, the oil pumping is automatically stopped;

[0034] Step 3: Start the steam heating, when the steam heating reaches 90°C, it will stop automatically, and the gas will be automatically started to continue heating;

[0035] Step 4: When the oil temperature reaches the set temperature, stop heating up, pump the heated oil into the feed pot 14, add various ingredients into the feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com