Magnetic coagulation water treatment method for in-situ magnetic seed separation and reuse

A magnetic coagulation and water treatment technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. , to achieve the effect of improving sewage treatment efficiency, reducing chemical consumption and operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

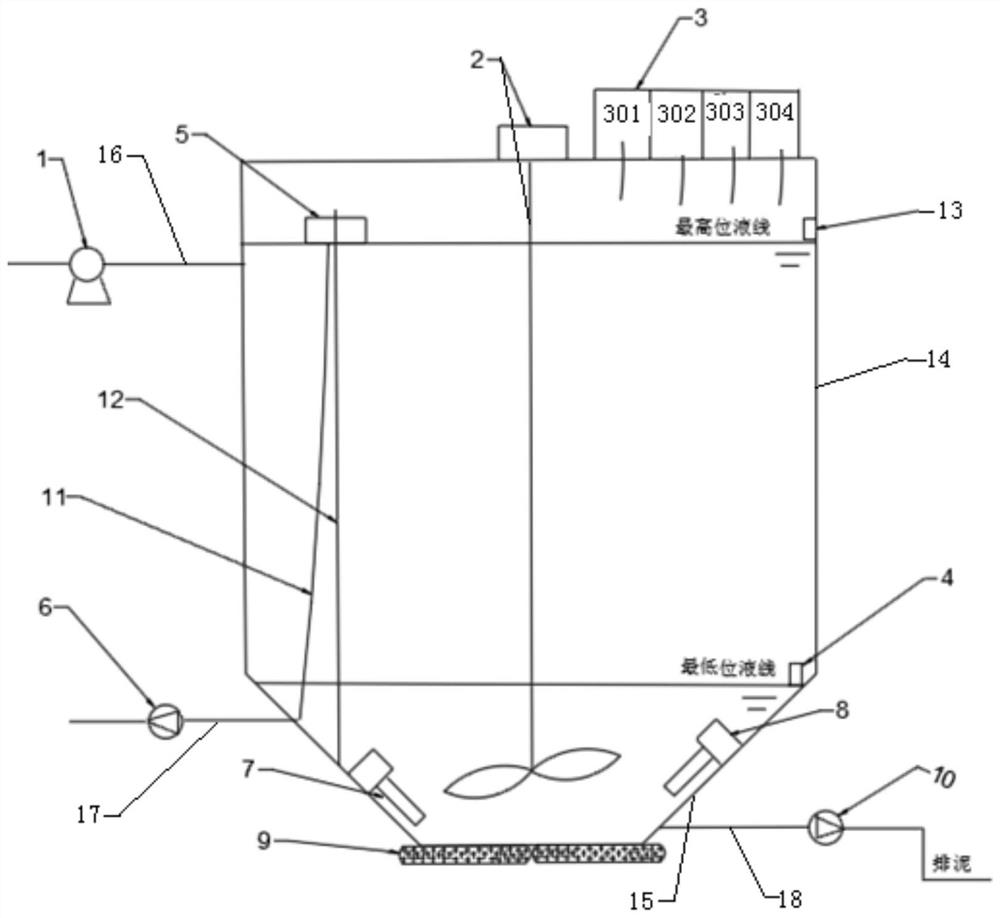

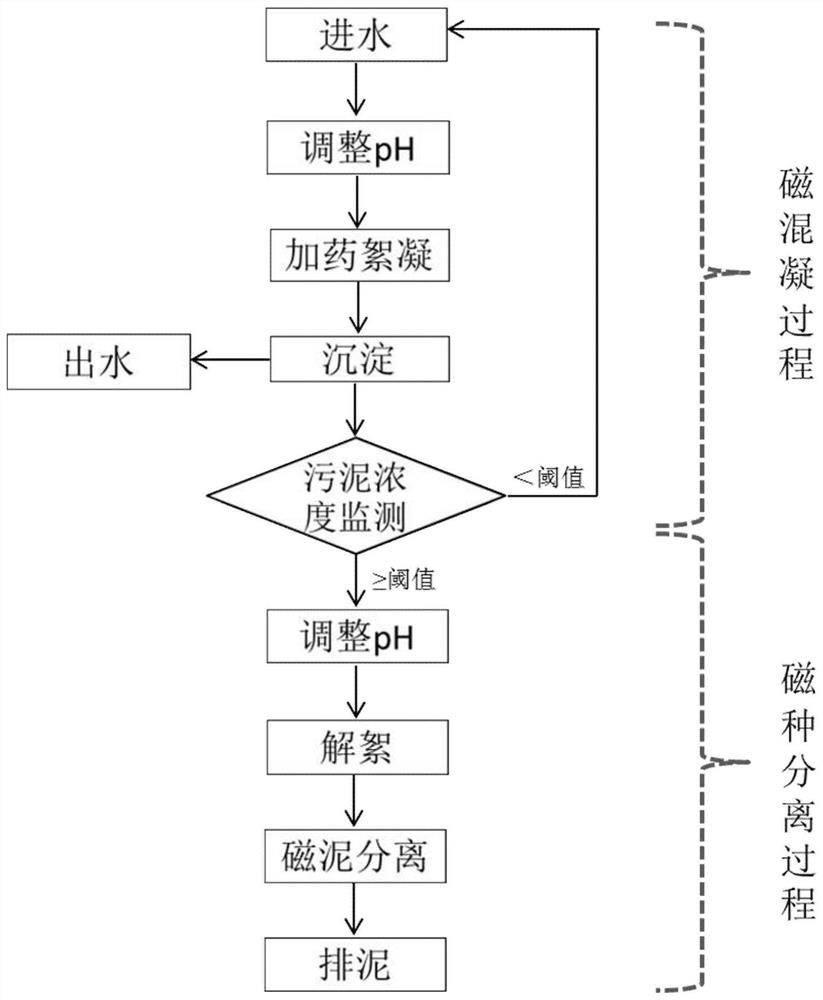

[0031] Such as figure 1 As shown, this embodiment provides a magnetic coagulation water treatment method for in-situ magnetic seed separation and reuse, using a reaction pool for water treatment, and a mixer 2 for stirring is installed in the reaction pool; the reaction pool includes a reaction cylinder 14 connected up and down And the mud hopper 15, the reaction cylinder 14 is a cylindrical or prismatic cylinder, which is convenient for flocculation and settlement, and the mud hopper 15 is conical or truncated, which is convenient for sludge collection and concentration. The reaction cylinder 14 is connected with a medicine box 3, and the medicine box 3 includes a magnetic seed box 301, a coagulant box 302, a coagulant box 303 and an acid-base regulator respectively filled with a magnetic seed, a coagulant, a coagulant and an acid-base regulator. Alkali conditioner tank 304. The mud hopper 15 is provided with a pH meter 7 for monitoring the pH value and a sludge concentratio...

Embodiment 2

[0048] Adopt the method in the embodiment 1 to process the surface water of a certain mild black and odorous river, the main operating parameters and process are:

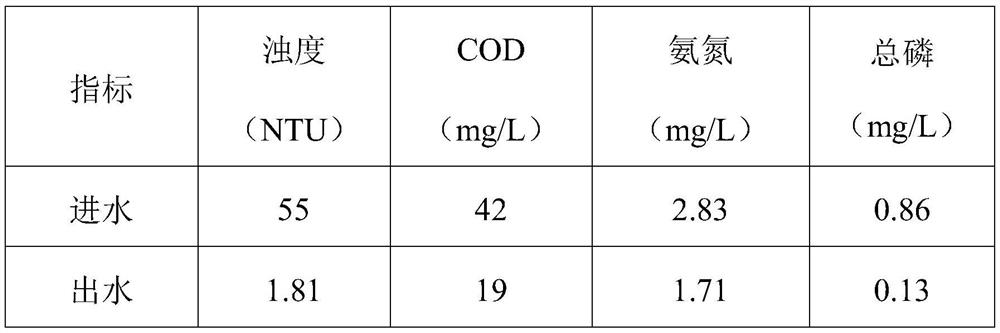

[0049] Magnetic coagulation treatment stage: adjust the pH to 7.0; the magnetic seed, coagulant and coagulant aid are 500 mesh ferric oxide magnetic powder, polyaluminum chloride and polyacrylamide respectively; the concentration of the three in the magnetic coagulation reaction system 150mg / L, 50mg / L and 0.1mg / L respectively; fast, medium and slow stirring speeds are 500r / min, 150r / min and 80r / min respectively; fast stirring, medium stirring, slow stirring and static settling time respectively 0.5min, 2min, 5min and 3min; set the drainage volume after static settling to 80% of the volume of the reaction tank, the sludge concentration threshold in the mud hopper is 6000mg / L, and the magnetic coagulation treatment step runs continuously for 10 rounds and then enters the magnetic seed separation and recovery stage. ...

Embodiment 3

[0056] Using the method in Example 1 to treat the biochemical secondary effluent of an urban sewage treatment plant, the main operating parameters and process are:

[0057] Magnetic coagulation treatment stage: adjust the pH to 7.2; the magnetic seed, coagulant and coagulant aid are 500 mesh ferric oxide magnetic powder, polyaluminum chloride and polyacrylamide respectively; the concentration of the three in the magnetic coagulation reaction system 200mg / L, 80mg / L and 0.2mg / L respectively; fast, medium and slow stirring speeds are 500r / min, 150r / min and 80r / min respectively; fast stirring, medium stirring, slow stirring and static settling time respectively 1min, 3min, 8min and 5min; set the drainage volume after static settling to 80% of the reaction tank volume, the sludge concentration threshold in the mud hopper is 4500mg / L, and the magnetic coagulation treatment step will enter the magnetic seed separation and recovery stage after 6 rounds of continuous operation .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com