Method for preparing low-carbon olefin from methanol

A technology of low-carbon olefins and methanol, which is applied in the direction of hydrocarbon cracking to hydrocarbons, chemical instruments and methods, and hydrocarbons from oxygen-containing organic compounds. Effects of increasing selectivity and yield and improving reaction selectivity

Pending Publication Date: 2022-03-15

北京惠尔三吉绿色化学科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The method requires multiple reactors and no yield data are given

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] This example illustrates the implementation effect of a method for producing light olefins from methanol through experimental data.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

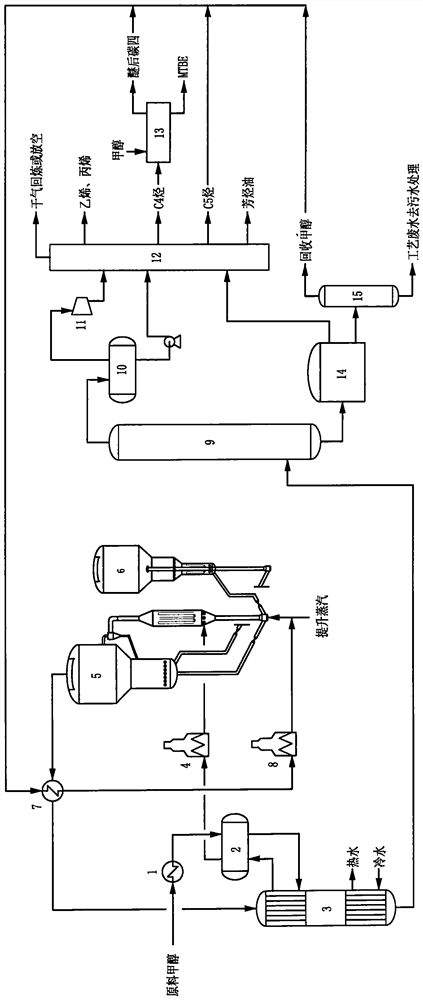

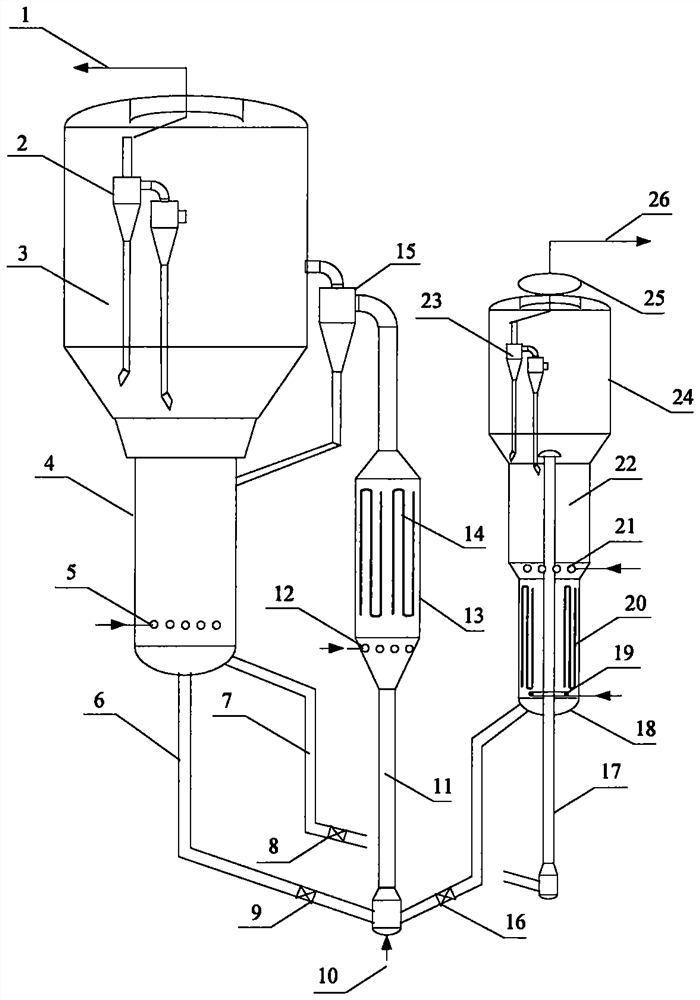

The invention relates to a method for preparing low-carbon olefin from methanol. In the method, the reaction of preparing low-carbon olefin from methanol and the reaction of preparing ethylene and propylene from etherified C4 and C5 through cracking are carried out in the same reactor. The reactor is a rapid fluidized bed reactor with a lifting pipe. The method comprises the following steps: vaporizing and preheating a raw material methanol, then feeding into a rapid fluidized bed reactor, and reacting under the action of a modified ZSM-5 molecular sieve catalyst to generate a product gas containing low-carbon olefin and obtain a spent catalyst at the same time; separating the product gas to obtain ethylene, propylene, C4, C5 and aromatic hydrocarbon oil, enabling the C4 to react in an etherification device to generate MTBE, returning the C5 and etherified C4 to the reactor through a riser, and cracking to generate ethylene and propylene; the spent catalyst is divided into two streams, one stream enters a regenerator to be burnt and regenerated to obtain a regenerated catalyst, and the other stream serves as a circulating spent catalyst, is mixed with the regenerated catalyst from the regenerator and then returns to the reactor through a lifting pipe.

Description

technical field [0001] The invention relates to a method for preparing light olefins by using methanol as a raw material. Specifically, a fast fluidized bed reactor and a supporting regenerator are used to make the reaction of methanol to olefins and the cracking reaction of C4C5 after ether be carried out in the same reactor, and share a reaction regeneration system and a set of reaction Product separation system. Background technique [0002] Ethylene and propylene are important basic chemical products, mainly produced by naphtha cracking. With the development of economy and society, the global demand for ethylene and propylene continues to grow rapidly, while at the same time non-renewable petroleum resources are increasingly scarce. The technology of synthesizing low-carbon olefins from coal and natural gas via methanol has sprung up, providing a non-petroleum route to prepare low-carbon olefins, giving full play to the advantages of my country's coal resources and mak...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C1/20C07C4/06C07C11/04C07C11/06C07C41/06C07C43/04C07C29/40

CPCC07C1/20C07C4/06C07C41/06C07C2529/40C07C11/04C07C11/06C07C43/046Y02P20/584Y02P30/20Y02P30/40

Inventor 龚小燕张瑞驰俞祥麟张丰豪张芳丁艳明赵春艳孙艳茹张浩

Owner 北京惠尔三吉绿色化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com