Ester-ether mixed viscosity-reducing polycarboxylic acid water reducer and preparation method thereof

A viscous polycarboxylate and hybrid technology, which is applied in the field of concrete admixtures, can solve the problems of difficult pumping, high-strength or ultra-high-strength concrete viscosity, etc., to improve appearance, improve slump performance, and increase space The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

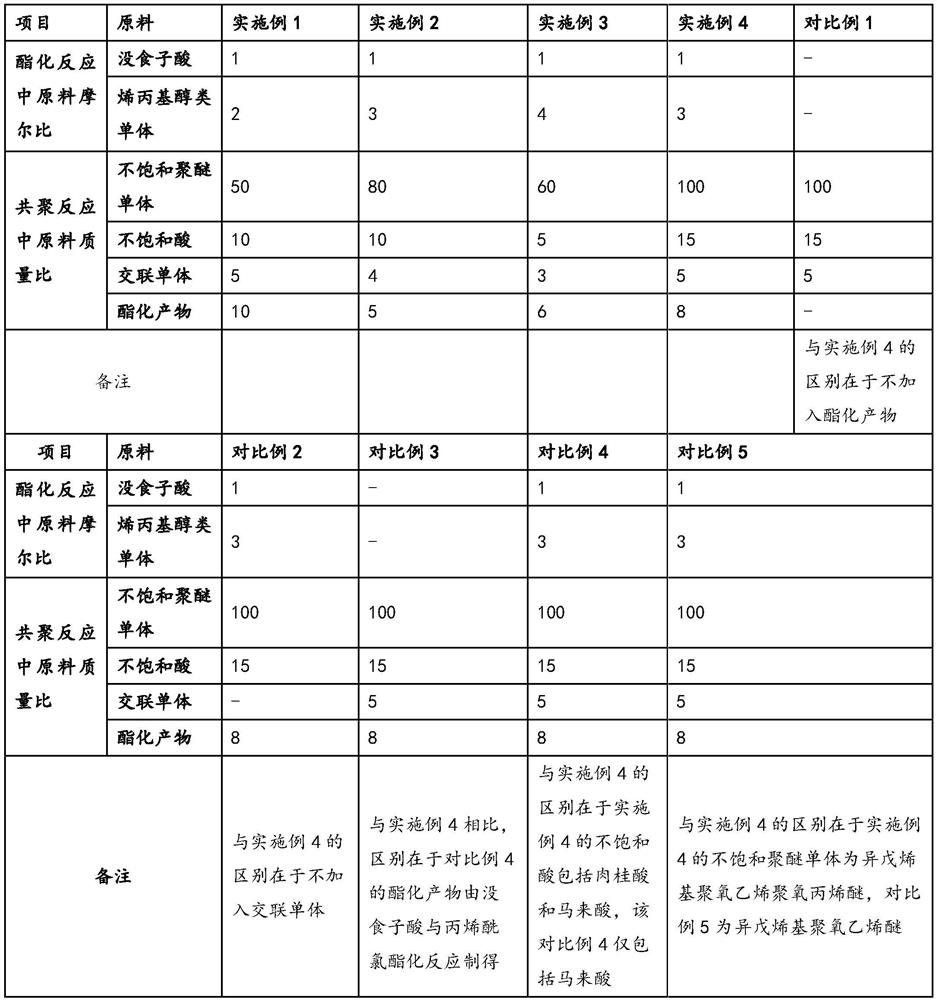

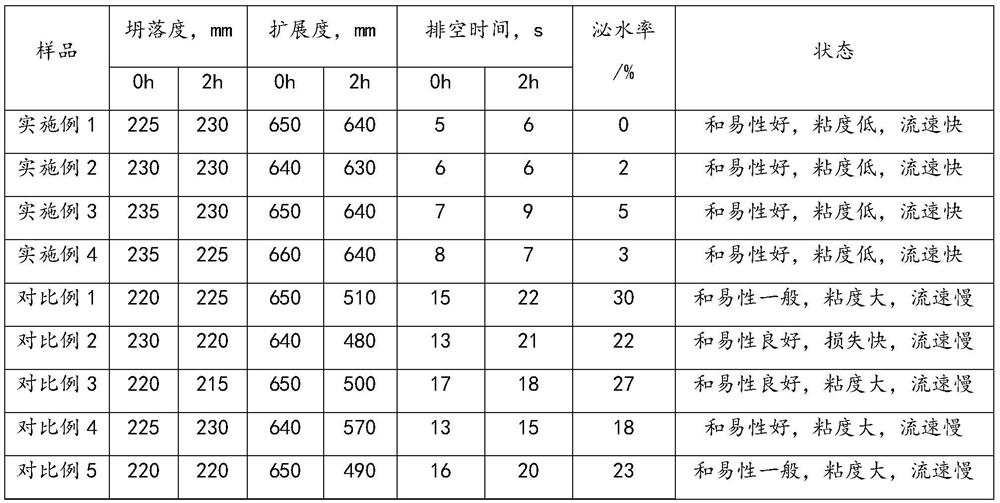

Examples

preparation example Construction

[0026] The invention provides a method for preparing an ester-ether mixed viscosity-reducing polycarboxylate water-reducer, which specifically includes the following steps:

[0027] (1) Esterification reaction: Mix gallic acid and allyl alcohol monomers in a certain proportion, add catalyst and polymerization inhibitor, and carry out esterification reaction at 80°C to 120°C for 4h to 5h under the protection of nitrogen. That is, the esterification product is obtained;

[0028] Wherein, the molar ratio of the gallic acid and the allyl alcohol monomer is 1: (2-4); the amount of the catalyst accounts for 1% to 3% of the total mass of the gallic acid and the allyl alcohol monomer; The amount of the polymerization inhibitor accounts for 0.1% to 2% of the total mass of gallic acid and allyl alcohol monomers;

[0029] Allyl alcohol monomers are selected from 2-methyl allyl alcohol, 3-methyl allyl alcohol, 2-chloro-2-propen-1-alcohol, 3-chloro allyl alcohol, 2-bromo-2- Propylene-1-o...

Embodiment 1

[0040] (1) Esterification reaction: blend gallic acid and 2-methallyl alcohol in a molar ratio of 1:2, add 3% p-toluenesulfonic acid and 0.5% of the total mass of gallic acid and 4-vinylbenzoic acid % of hydroquinone, continue to feed nitrogen, carry out esterification reaction at 120 ° C for 4 hours, and obtain the esterification product.

[0041] (2) Copolymerization reaction: in parts by mass, add 50 parts of isopentenyl polyoxyethylene polyoxypropylene ether (molecular weight: 1000) and 25 parts of water into the reactor, and after stirring and dispersing evenly, add 2 parts of hydrogen peroxide, the reaction temperature is 25°C, after 10 minutes, add solution B and solution C dropwise;

[0042] Wherein, solution B is that 10 parts of mass concentrations are 10% sodium hypophosphite solution; Solution C is 10 parts of esterification products, 5 parts of polyethylene glycol maleic acid monoester (polyethylene glycol is PEG-400), 6 parts A solution of 1 part cinnamic acid, ...

Embodiment 2

[0045] (1) Esterification reaction: blend gallic acid and 2-chloro-2-propen-1-ol in a molar ratio of 1:3, add concentrated sulfuric acid accounting for 1% of the total mass of gallic acid and 4-vinylphenylacetic acid and 0.1% phenothiazine, and continuously feed nitrogen, and perform esterification reaction at 110° C. for 4 hours to obtain an esterified product.

[0046] (2) Copolymerization reaction: In parts by mass, 80 parts of methallyl polyoxyethylene polyoxypropylene ether (molecular weight is 500) and 40 parts of water are added to the reactor, and after stirring and dispersing evenly, one-time Add 1 part of hydrogen peroxide, the reaction temperature is 20°C, after 10 minutes, add solution B and solution C dropwise;

[0047] Wherein, solution B is the L-ascorbic acid solution that 1 part of mass concentration is 10%; Solution C is 5 parts of esterification product, 4 parts of polyethylene glycol maleic acid monoester (polyethylene glycol is PEG-600), 5 parts A solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com