Preparation method of metal support plate for fuel cell

A metal support, fuel cell technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems of uneven pore size, easy deformation, unstable gas flow, etc., and achieve high cost, small deformation, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

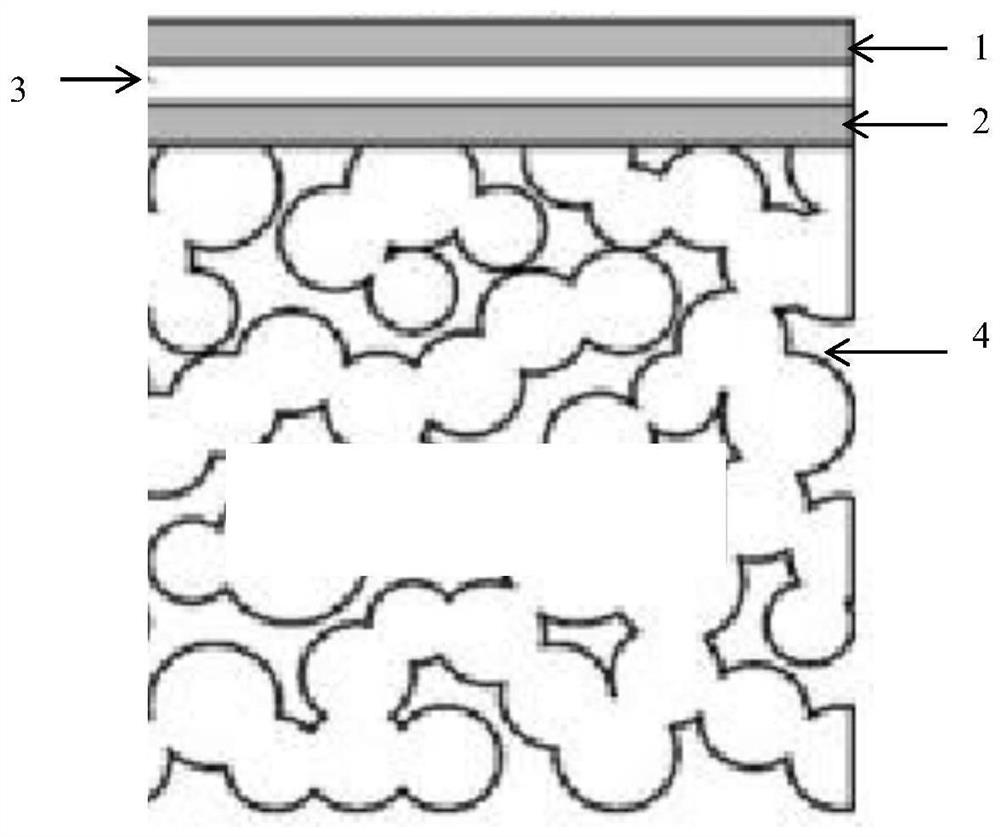

[0034] like Figure 2 to Figure 4 Shown is the first preferred embodiment of the present invention.

[0035] The preparation method of the metal support plate for the fuel cell in this embodiment includes the following steps in sequence:

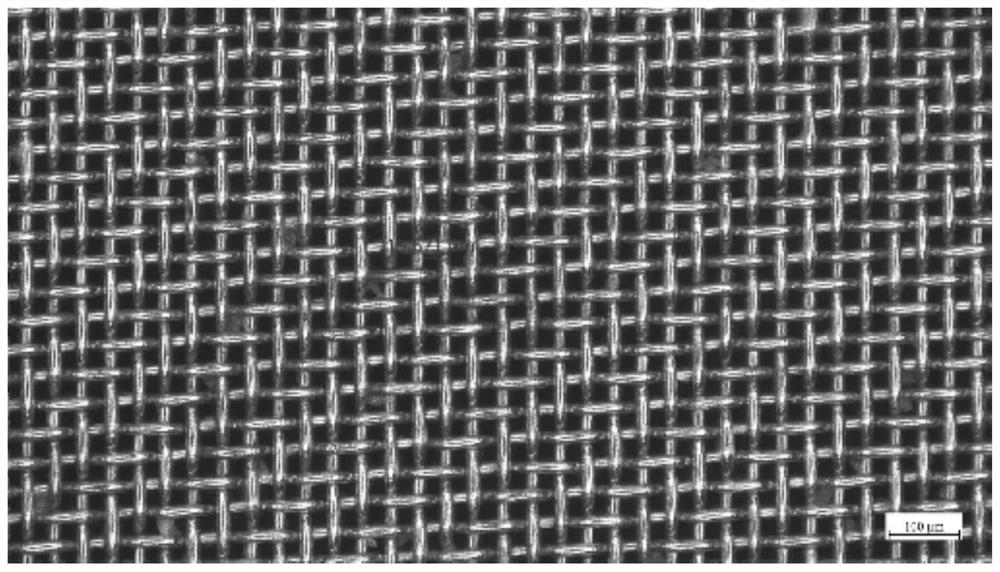

[0036] 1) Use a wire mesh with a mesh number of 700, see figure 2 As shown, the wire mesh is made of 304L austenitic stainless steel; in terms of mass percentage, the stainless steel includes the following components: C: 0.015%, Cr: 19.2%, Mn: 0.6%, Si: 0.8%, Ni: 10.3 %, iron: balance;

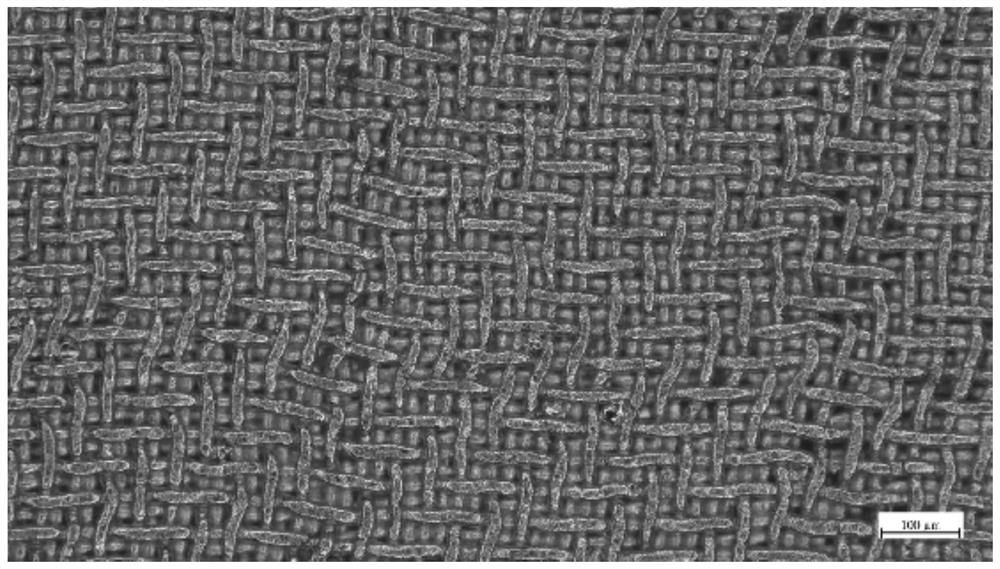

[0037] 2) Folding the wire mesh in step 1) to obtain a multilayer wire mesh, the number of folded layers is 10 layers;

[0038]3) Roll the wire mesh layer in step 2), then put it into a vacuum sintering furnace, sinter at a vacuum degree of 0.1 Pa, a sintering temperature of 1300° C., and a sintering time of 60 minutes, and take out the multi-layer after sintering and cooling. wire mesh;

[0039] 4) Cut the sintered multi-layer wire mesh into a metal s...

Embodiment 2

[0046] The difference between this embodiment and the above-mentioned Embodiment 1 is only:

[0047] The material of the metal wire mesh selected in step 1) is different, specifically, 430L ferritic stainless steel wire mesh is selected, and the mesh number of the wire mesh is 700 meshes; according to the mass percentage, the stainless steel wire mesh includes the following components: including The following components: C: 0.010%, Cr: 17.4%, Mn: 0.8%, Si: 0.5%, Iron: balance;

[0048] In step 2), the wire mesh is stacked, and the wire mesh is stacked in 10 layers, placed on the corundum board, and then the corundum board of the same size covers the stacked wire mesh, and the corundum board (ceramic board) No heavy objects are placed;

[0049] Step 3) Put the above-mentioned ceramic plate and wire mesh together into a push-boat sintering furnace, and sinter in high-purity hydrogen with a dew point lower than -40°C, at a sintering temperature of 1320°C and a sintering time of ...

Embodiment 3

[0055] The difference between this embodiment and the above-mentioned embodiment 2 is only: the material of the metal wire mesh selected in step 1) is different, specifically, FeCrAl heat-resistant steel wire mesh is selected, and the mesh number of the wire mesh is 325 meshes, and the aforementioned heat-resistant steel wire mesh is used. The net, in terms of mass percentage, includes the following components: C: 0.08%, Cr: 18.7%, Al: 2.8%, Mn: 0.4%, Si: 1.1%, iron: balance;

[0056] Step 2) The above-mentioned metal wire mesh is in the form of stacking, stack the metal wire mesh in 6 layers, place it on the corundum board, and then cover the stacked wire mesh with the corundum board of the same size, on the corundum board (ceramic board) Place a 2kg weight;

[0057] Step 3) the sintering temperature is 1340°C, and the sintering time is 50min;

[0058] Step 4) After cutting, the size of the obtained metal substrate is 110mm×110mm×0.53mm.

[0059] The aforementioned anode sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com