Graphene transfer method for stripping polymer support material based on alcohol solvent

A transfer method and alcohol solvent technology, which is applied in the field of material chemistry, can solve the problems of incomplete removal of PMMA, residual PMMA, and graphene damage, and achieve the effects of improving transfer efficiency and application efficiency, high-quality transfer, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

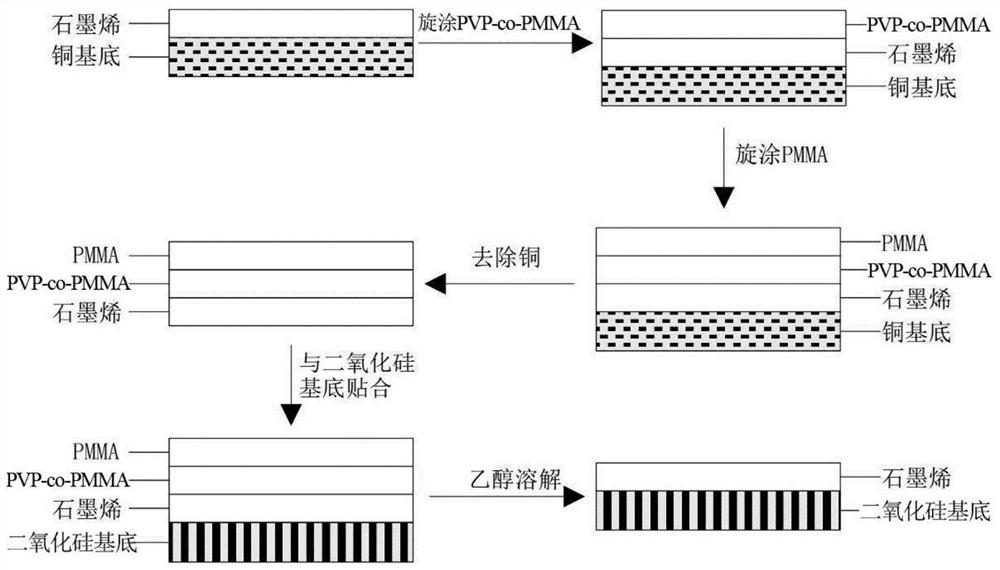

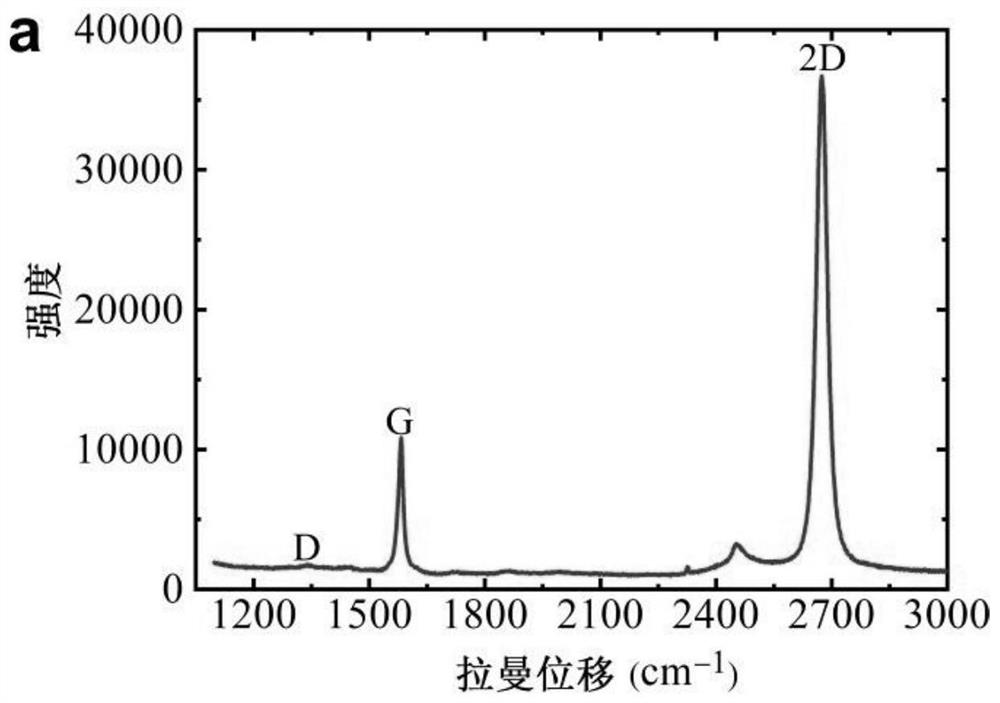

[0046] This embodiment provides a graphene transfer method based on alcohol solvent stripping polymer support material, such as figure 1 and figure 2 shown, including the following steps:

[0047] Step 1, according to the weight ratio of PVP-co-PMMA powder (purchased from Sigma-Aldrich, product number is 474576, CAS number: 24979-71-3) and cyclopentanone is 1:4, dissolve PVP-co-PMMA In cyclopentanone, the filtered filtrate is PVP-co-PMMA polymer solution; according to the weight ratio of PMMA powder and dibromomethane is 1.5:98.5, PMMA powder is dissolved in dibromomethane, and the filtered filtrate is PMMA high-molecular solution. molecular solution.

[0048] Step 2, spin coating PVP-co-PMMA polymer solution on the graphene (commercially available) surface of copper substrate, the rotating speed of spin coating is 3000rpm / s, heat 60min at 80 ℃ after spin coating, on graphene surface A PVP-co-PMMA film with a thickness of 2 μm was formed on it.

[0049] Step 3, spin-coat ...

Embodiment 2

[0058] This embodiment provides a method for transferring graphene to an organic electro-optic polymer film by using the method of the present invention. The specific process is the same as in Example 1, except that the silicon dioxide substrate in Example 1 is replaced by an organic electro-optic polymer. film.

[0059] As a comparison, a small amount of acetone was dropped on the organic electro-optic polymer film, and the damage of acetone to the organic electro-optic polymer film was observed.

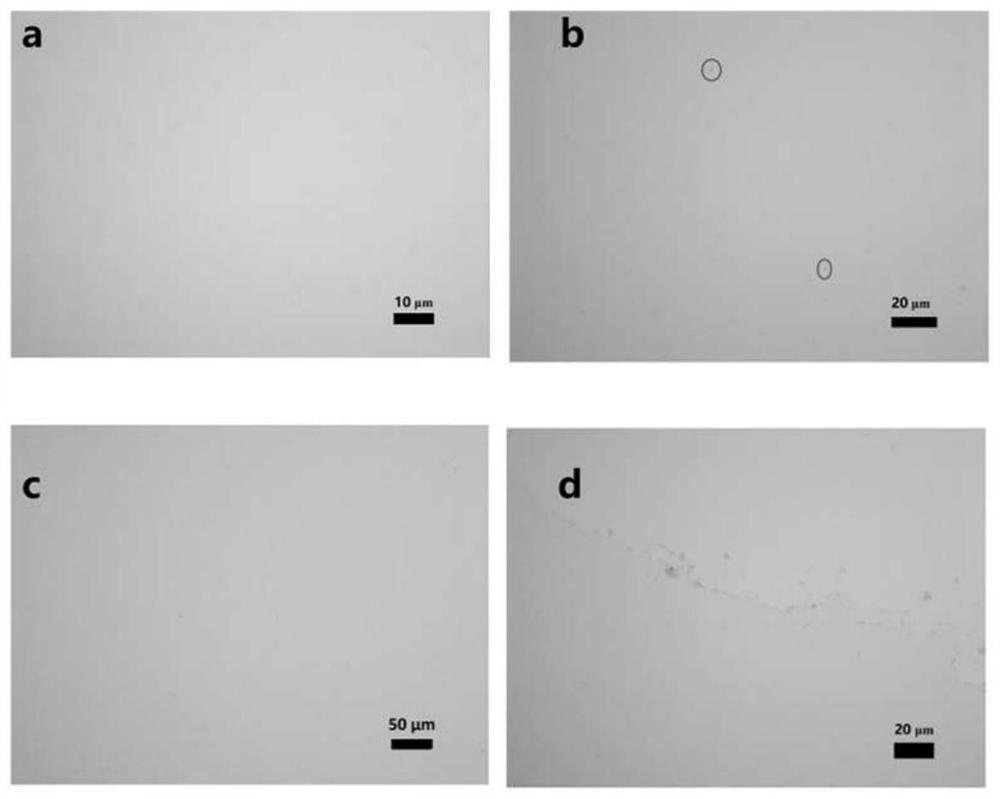

[0060] Figure 4 It is the photo of the organic electro-optic polymer film in Example 2 before and after being destroyed by acetone. It can be seen from the comparison that the organic polymer material is easily destroyed by acetone.

[0061] Figure 5 For Example 2, graphene is transferred onto an organic electro-optic polymer film using the method of the present invention, before and after peeling off the supporting polymer PVP-co-PMMA and PMMA. The organic electro-optic poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com