Anodic oxidation dyeing additive, anodic oxidation dyeing additive solution, preparation method of anodic oxidation dyeing additive solution and anodic oxidation dyeing method

A technology of anodizing and dyeing methods, applied in the direction of anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of flow marks, uneven dyeing, and different color at the edge of the hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The embodiment of the present application also provides a method for preparing an anodic oxidation dyeing additive solution, comprising the following steps:

[0051] providing said anodizing dyeing additive, and water; and

[0052] Adding the anodic oxidation dyeing additive into water, heating and stirring to obtain the anodic oxidation dyeing additive liquid.

[0053] In at least one embodiment, in the anodic oxidation dyeing additive solution, the mass ratio of the main agent, auxiliary agent, pH stabilizer, antibacterial agent, and water is (7.5-9): (7-8): (0.8-1.2): (0.03-0.04): (18-20).

[0054] In at least one embodiment, the temperature of the heat treatment is 40-60° C., and the heating time is 4-8 hours.

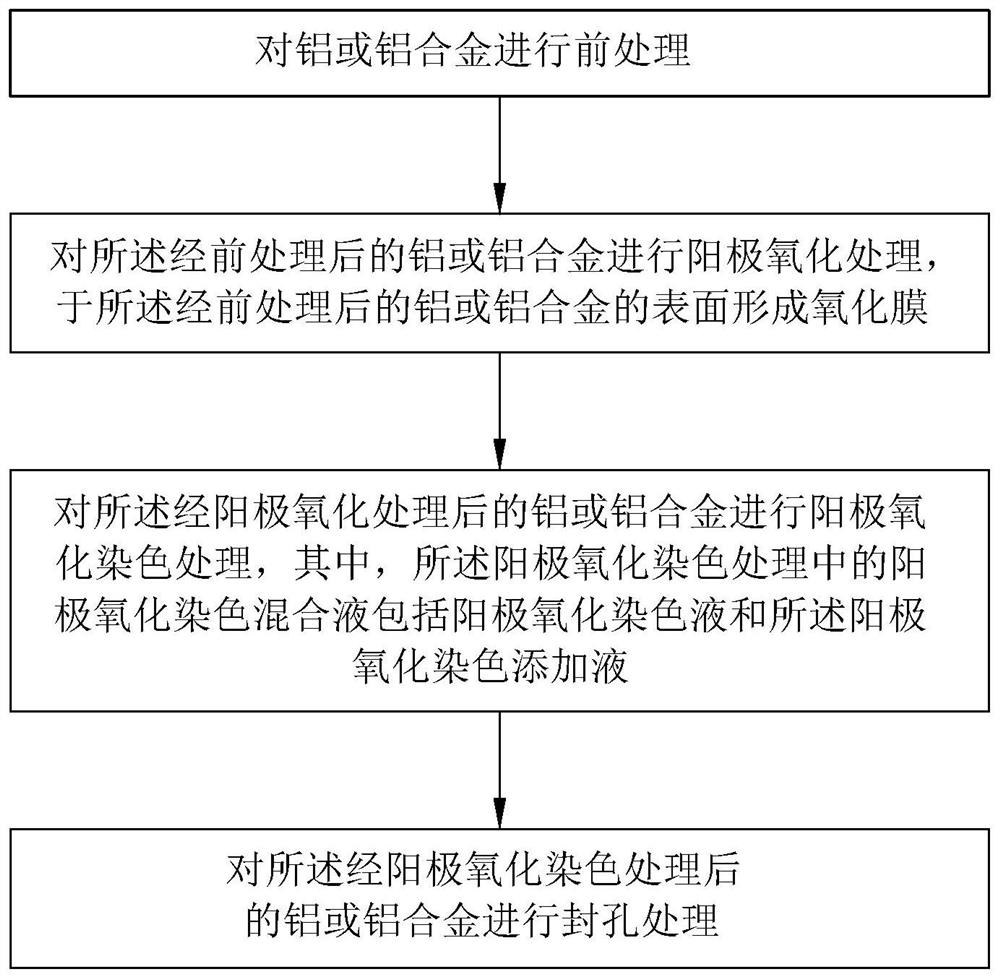

[0055] ginseng figure 1 , the embodiment of the present application also provides an anodic oxidation dyeing method.

[0056] Described anodic oxidation dyeing method comprises the following steps:

[0057] Pretreatment of aluminum or aluminum alloy;

...

Embodiment 1

[0095] Provide methanesulfonic acid, tribasic sodium carboxylate, tribasic carboxylic acid, sorbic acid, and deionized water, wherein, said methanesulfonic acid, tribasic sodium carboxylate, tribasic carboxylic acid, sorbic acid, and deionized water The mass ratio of ionized water is 7.5:7:0.8:0.03:18-20;

[0096] adding the methanesulfonic acid, sodium tricarboxylate, tricarboxylic acid, and sorbic acid into deionized water to obtain an anodic oxidation dyeing additive solution;

[0097] Provide anodic oxidation dyeing solution, wherein, said anodic oxidation dyeing solution comprises the chromium complex dye and deionized water that the model produced by Okuno Company is BU30P and deionized water, and the content of said chromium complex dye is 1.48g / L;

[0098] The anodic oxidation dyeing additive solution was added to the anodic oxidation dyeing liquid to obtain the anodic oxidation dyeing mixed liquid of Example 1, wherein the pH value of the anodic oxidation dyeing mixed...

Embodiment 2

[0104] Provide methanesulfonic acid, tribasic sodium carboxylate, tribasic carboxylic acid, sorbic acid, and deionized water, wherein, said methanesulfonic acid, tribasic sodium carboxylate, tribasic carboxylic acid, sorbic acid, and deionized water The mass ratio of ionized water is 7.5:7:0.8:0.035:18-20;

[0105] adding the methanesulfonic acid, sodium tricarboxylate, tricarboxylic acid, and sorbic acid into deionized water to obtain an anodic oxidation dyeing additive solution;

[0106] An anodic oxidation dyeing solution is provided, wherein the anodic oxidation dyeing solution includes a chromium complex dye and deionized water produced by Japan Okuno Co., Ltd. as a model of BU30P, and the content of the chromium complex dye is 1.45g / L;

[0107] The anodic oxidation dyeing additive solution was added to the anodic oxidation dyeing liquid to obtain the anodic oxidation dyeing mixed liquid of Example 2, wherein the pH value of the anodic oxidation dyeing mixed liquid of Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com