An energy storage system using dry ice sublimation

An energy storage system and dry ice technology, applied in the field of energy storage systems using dry ice sublimation, can solve problems such as low energy utilization, waste, and excess energy, and achieve the effects of improving commercial applications, working efficiency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to examples and accompanying drawings, but this does not limit the protection scope of the present invention.

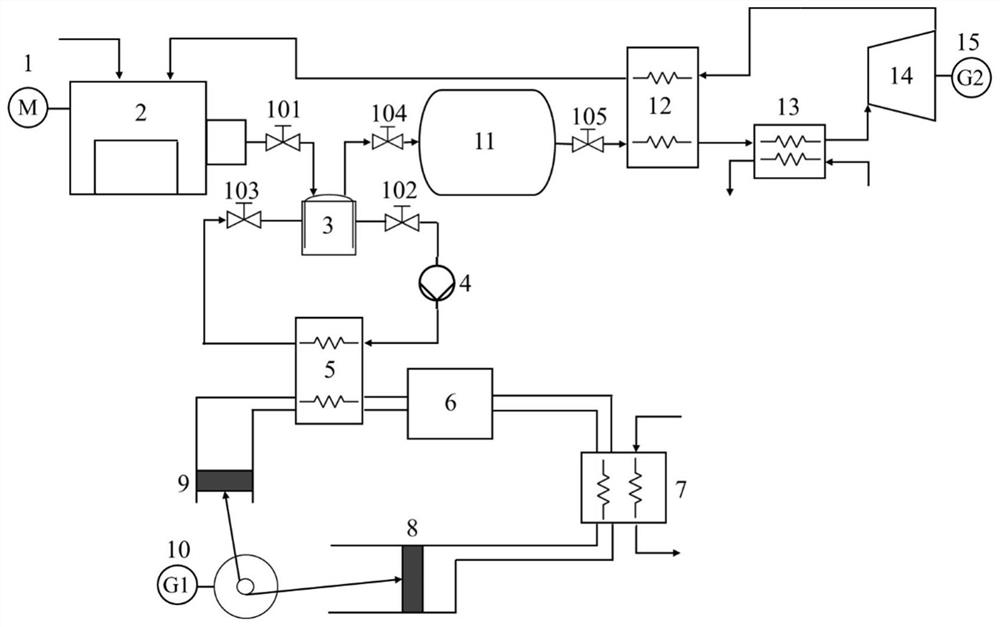

[0027] see figure 1 , figure 1 It is a schematic diagram of the structure of the energy storage system using dry ice sublimation. The system of the present invention includes: main motor 1, dry ice making machine 2, dry ice storage tank 3, pump 4, Stirling engine cold end heat exchanger 5, Stella engine heat accumulator 6, Stirling engine hot end heat exchange 7, first Stirling engine piston 8, second Stirling engine piston 9, first generator 10, high pressure carbon dioxide surge tank 11, regenerative heater 12, heater 13, turbine 14, second The generator 15, the first valve 101, the second valve 102, the third valve 103, the fourth valve 104, the fifth valve 105 and their connecting parts.

[0028] The system mainly consists of three subsystems:

[0029] The dry ice production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com