Method for detecting tetraethylene glycol dimethyl ether in leather

A tetraethylene glycol dimethyl ether and detection method technology, which is applied in the field of chemical detection, can solve the problems of unreported tetraethylene glycol dimethyl ether detection methods and related standards, and achieve anti-sample impurity interference and strong selectivity , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

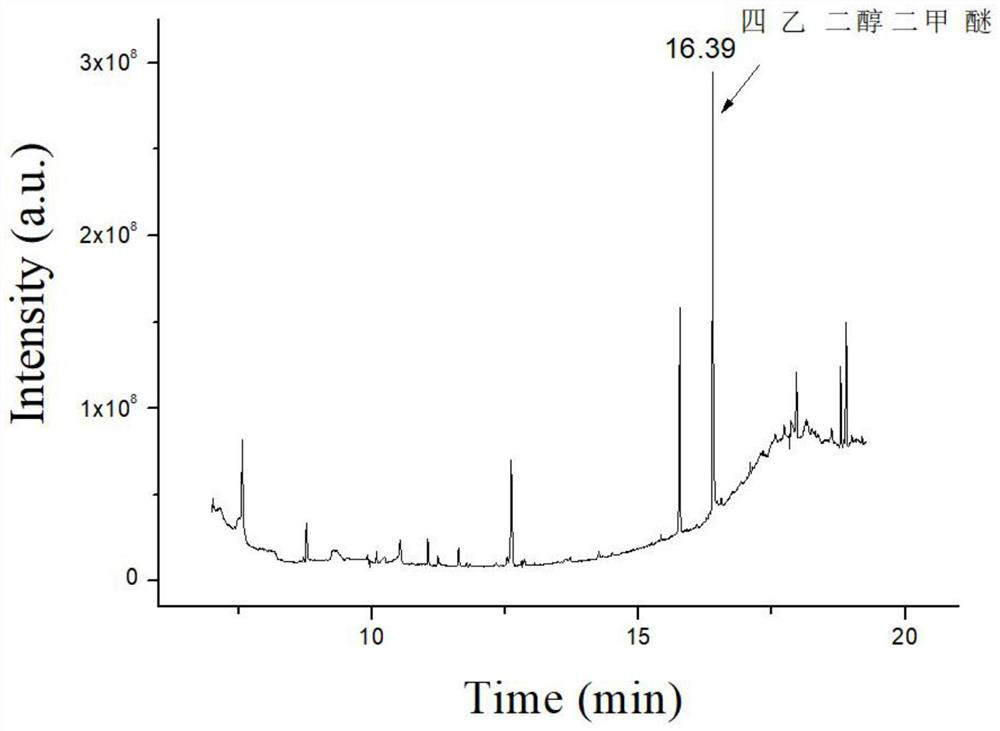

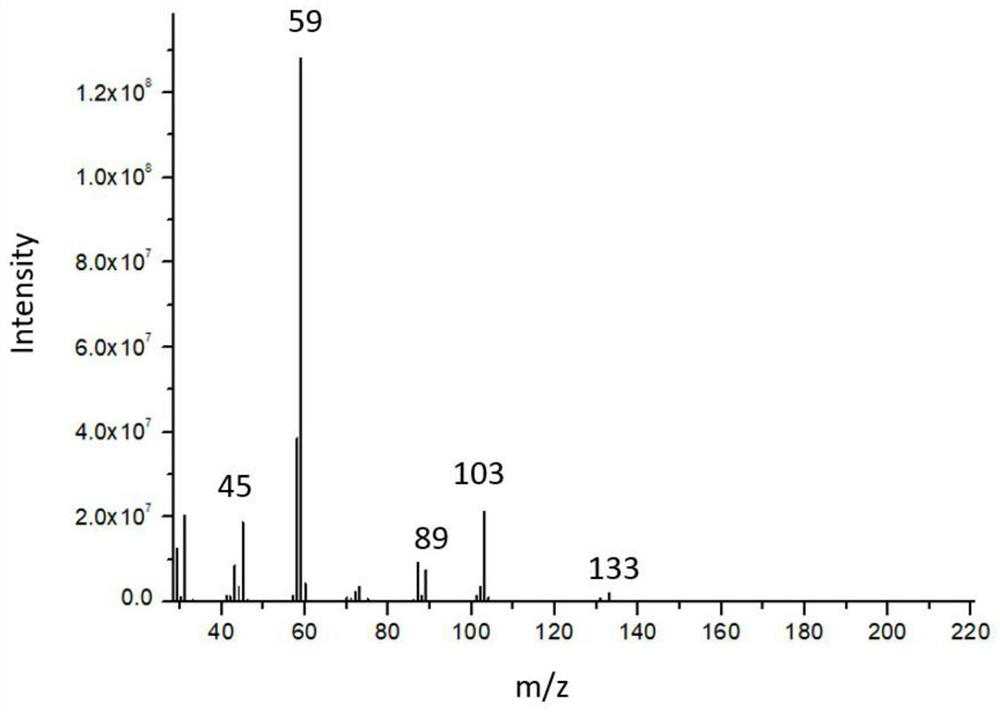

[0082] The mensuration of tetraethylene glycol dimethyl ether in the bovine leather sample of embodiment 1

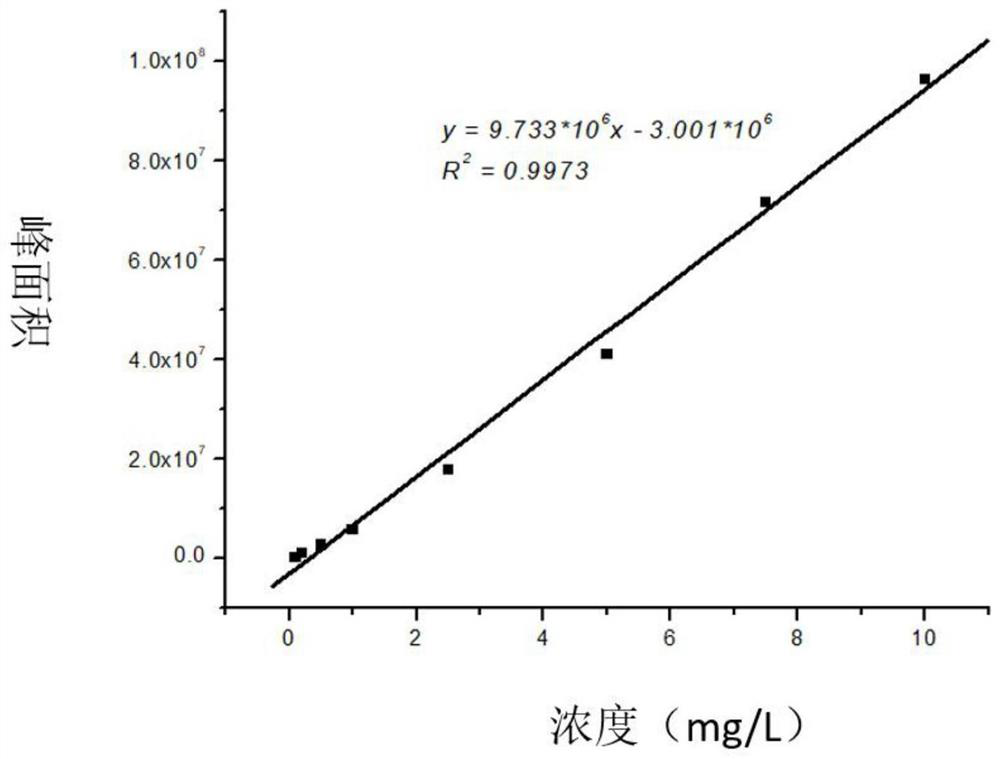

[0083] (1) Preparation of standard solution: pipette 0.01013g of tetraethylene glycol dimethyl ether standard substance with a pipette gun, use methanol as solvent, set the volume to 100mL, and obtain 101.3mg / L tetraethylene glycol dimethyl ether standard stock solution, dilute the tetraethylene glycol dimethyl ether standard stock solution into various concentrations of tetraethylene glycol dimethyl ether standard solutions, the concentrations are 0.5, 1.0, 2.5, 5.0, 7.5, 10.0 mg / L respectively.

[0084] (2) Sampling and ultrasonic extraction: Use scissors or a rag to cut the bovine leather sample without tetraethylene glycol dimethyl ether into small pieces of 2mm × 2mm, and accurately weigh 1.00g (+0.01g) Put the sample in a glass bottle with a screw cap (volume 40mL), add 10mL extraction solvent acetone and 0.2mL 1.0mg / L tetraethylene glycol dimethyl ether standard ...

Embodiment 2

[0109] The mensuration of tetraethylene glycol dimethyl ether in embodiment 2 pig leather

[0110] (1) Sampling and ultrasonic extraction: Cut the pig leather sample into small pieces of 2mm×2mm or less with scissors or a rag machine, accurately weigh 1.00g of the sample and place it in a glass bottle with a screw cap (volume 40mL), Add 10 mL of extraction solvent acetone, cover and screw tightly, vortex and mix well, and put it into an ultrasonic water bath at 30°C for ultrasonic treatment for 30 min. Collect the supernatant, rinse the residue with 10 mL of acetone and extract again for 5 min, and combine the sample extracts into a concentration bottle for subsequent concentration operations.

[0111] (3) Concentration: Place the concentrating bottle on a rotary evaporator, under the conditions of vacuum degree of 550mbar, water bath temperature of 40°C, and rotation speed of 20rpm, evaporate and concentrate to near dryness, blow dry with nitrogen, add 3.0mL of n-hexane to di...

Embodiment 3

[0134] The mensuration of tetraethylene glycol dimethyl ether in the bovine leather sample of embodiment 3

[0135] (1) Sampling and ultrasonic extraction: Use scissors or a rag to cut the cow leather sample into small pieces of 2mm×2mm or less, and accurately weigh 18 samples of 1.00g and place them in glass bottles with screw caps (volume 40mL). ), add 10mL extraction solvent acetone respectively, add 0.1mL 10mg / L tetraethylene glycol dimethyl ether standard solution into 6 of them and cover and tighten tightly, add 0.2mL Add 10mg / L tetraethylene glycol dimethyl ether standard solution and cap it tightly, add 0.1mL 100mg / L tetraethylene glycol dimethyl ether standard solution to the remaining 6 glass bottles and cap it tightly. After vortex mixing, ultrasonic treatment was performed for 30 min in an ultrasonic water bath at 30°C. The supernatants were collected and the residue was rinsed with 10 mL of acetone to extract again for 5 min, and the sample extracts were combined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com