Non-magnetic temperature control device for atom magnetic detection and measurement method

A temperature control device and magnetic detection technology, which is applied to the magnetic measurement environment, the measurement device, the size/direction of the magnetic field, etc., can solve the problems of the large size of the device, the limitation of the measurement range of the magnetometer, the disturbance of the optical path, etc., to improve the sensitivity, The compactness and practicality of the device, the effect of extending the measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

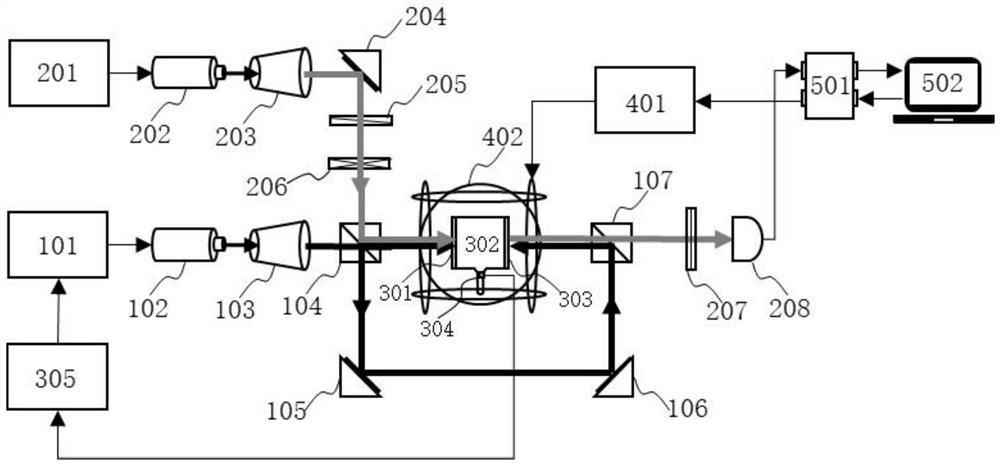

[0043] see Figure 1-3 , a non-magnetic temperature control device for atomic magnetic detection, including a heating optical path module and an atomic gas chamber temperature control module;

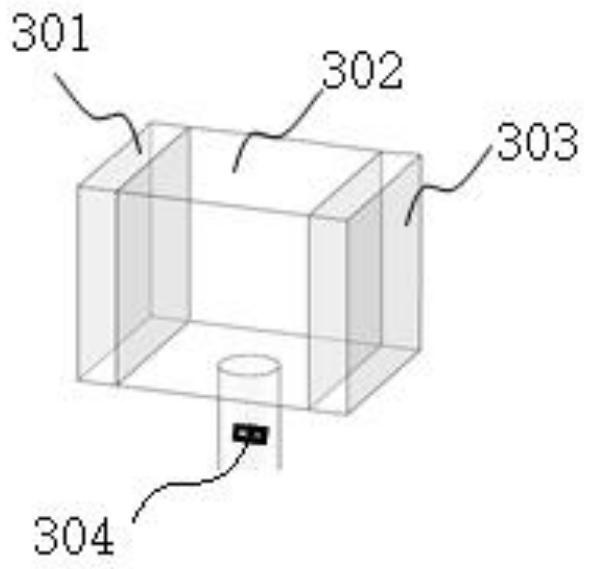

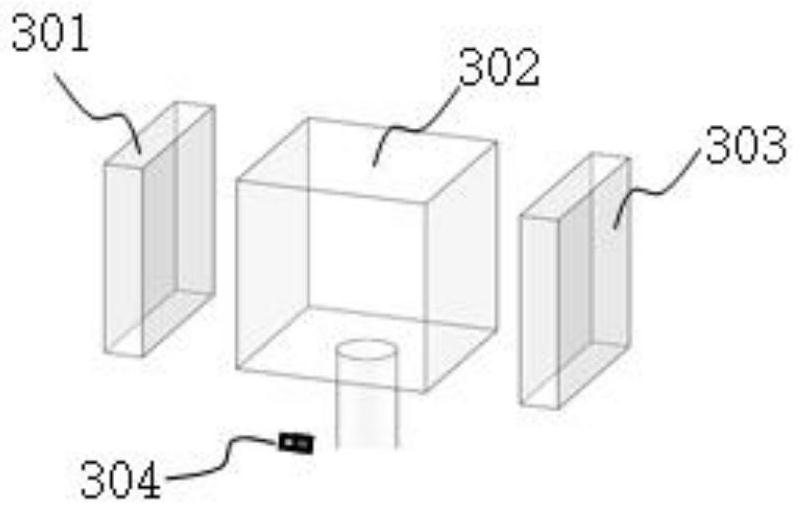

[0044] The atomic gas chamber temperature control module is used to absorb the heating laser to generate gaseous alkali metal atoms with the required atomic number density, which includes a first optical filter 301, an atomic air chamber 302, a second optical filter 303, and a temperature measuring resistor 304 and a temperature control processor 305; the first optical filter 301 and the second optical filter 303 are closely arranged on the opposite sides of the atomic gas chamber 302, and are used to transmit the working laser light and absorb the heating laser light at the same time; The atomic gas chamber 302 is filled with alkali metal atoms (specifically, cesium atoms) as a working substance, and the atomic gas chamber 302 is provided with a gas-filled tube for supplementing alkali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com