Preparation method of thin film and light emitting diode

A light-emitting diode and thin-film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem of unbalanced hole transmission efficiency and electron transmission rate of light-emitting diodes, so as to improve photoelectric performance and working life , Improve the interface contact performance and reduce the effect of interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

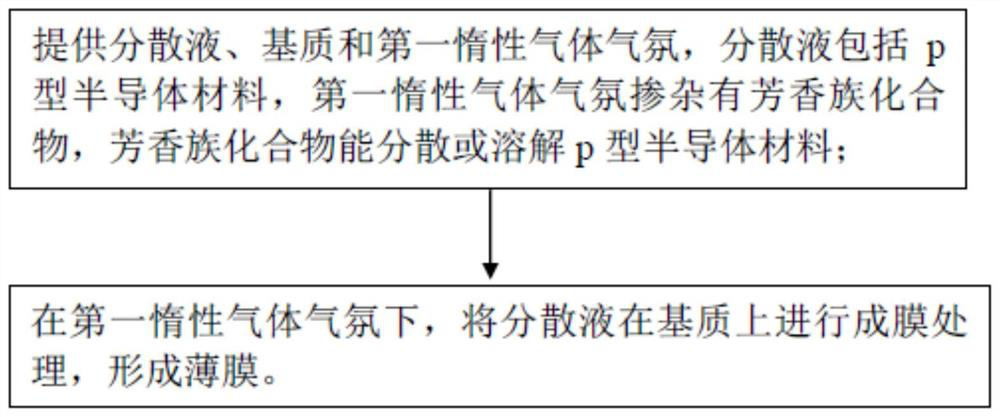

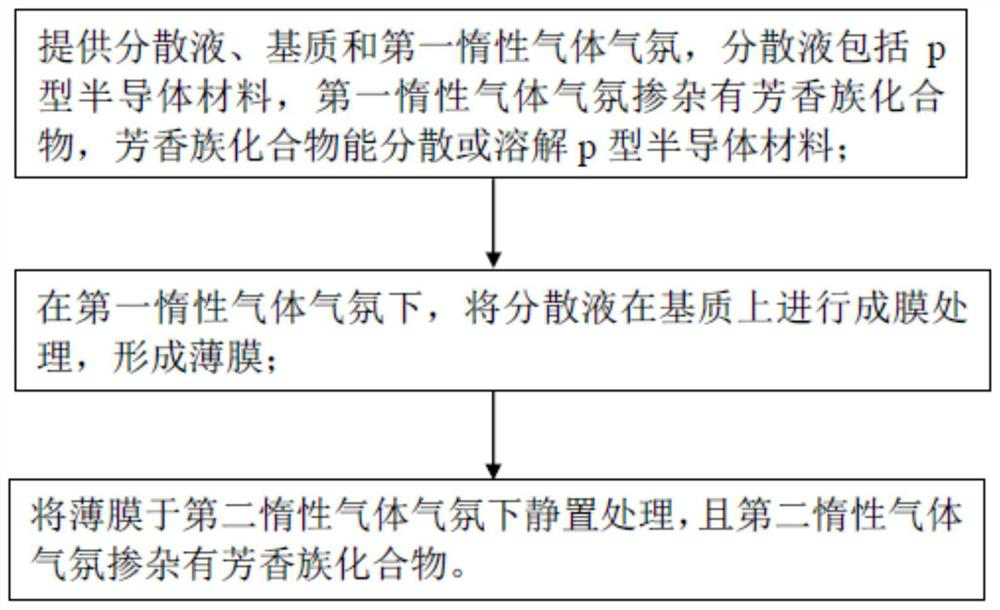

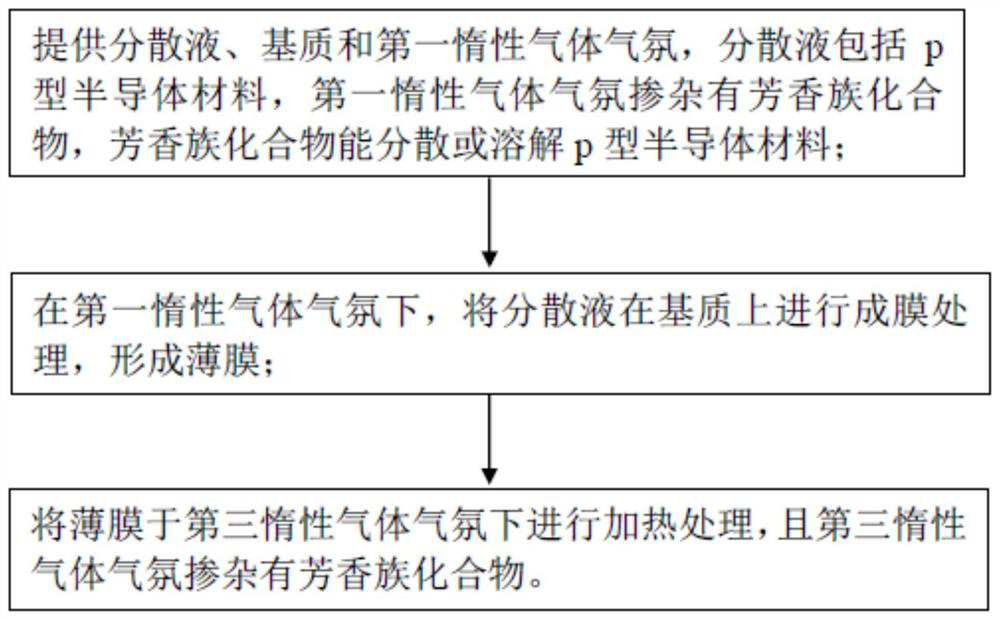

[0032] Such as figure 1 As shown, the embodiment of the present application provides a method for preparing a thin film, comprising the following steps:

[0033] S01. Provide a dispersion liquid, a matrix, and a first inert gas atmosphere, the dispersion liquid includes a p-type semiconductor material, the first inert gas atmosphere is doped with an aromatic compound, and the aromatic compound can disperse or dissolve the p-type semiconductor material;

[0034] S02. Under the first inert gas atmosphere, perform film-forming treatment on the substrate to form a thin film.

[0035] In the method for preparing a thin film provided in an embodiment of the present application, a dispersion liquid comprising a p-type semiconductor material is formed into a film under a first inert gas atmosphere, and the first inert gas atmosphere is doped with an aromatic substance capable of dispersing or dissolving a p-type semiconductor material. A group of compounds, so that in the process of ...

Embodiment 1

[0068] This embodiment provides a top-emitting positive quantum dot light-emitting diode, and its preparation method includes:

[0069] (1) On the ITO substrate, spin-coat PEDOT:PSS at a speed of 5000 for 30 seconds, then heat at 150°C for 15 minutes;

[0070] (2) Doping gaseous chlorobenzene in a glove box environment full of Ar gas atmosphere, and making the volume concentration of gaseous chlorobenzene be 0.5%, then putting the device prepared in step (1) into the glove box;

[0071] (3) Spin-coat TFB (8mg / mL) on the PEDOT:PSS layer at a speed of 3000 for 30 seconds, then heat at 80°C for 10 minutes;

[0072] (4) Put the device prepared in step (3) into a vacuum container, and then replace the gas atmosphere in the glove box with an Ar atmosphere;

[0073] (5) Spin-coat quantum dots (20mg / mL) on the TFB layer at a speed of 2000 for 30 seconds;

[0074] (6) Spin-coat ZnO (30mg / mL) on the quantum dot layer at a speed of 3000 for 30 seconds, then heat at 80°C for 30 minutes;...

Embodiment 2

[0078] This embodiment provides a top-emitting upright quantum dot light-emitting diode, the preparation method of which is basically the same as that of Embodiment 1, the difference is that after heating at 80°C for 10 minutes in step (3), the device is put into an airtight container Standing for 50min, and the atmosphere environment in the airtight container is Ar atmosphere (volume concentration is 95%) and gaseous chlorobenzene (volume concentration 5%), such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com