Preparation method of secondary functionalized double-coating modified polyether sulfone lithium-sulfur battery diaphragm

A lithium-sulfur battery and sulfonated polyethersulfone technology, which is applied in secondary batteries, secondary battery repair/maintenance, lithium batteries, etc., can solve problems such as low melting point, inability to effectively suppress the shuttle effect, low discharge capacity and Coulombic efficiency, etc. Problems, to achieve good adsorption, excellent rate performance, improve the effect of puncture strength and liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

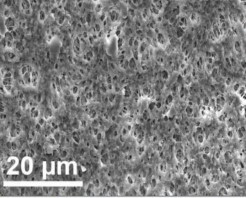

Image

Examples

Embodiment 1

[0028] Example 1: at N 2 Atmosphere, under the conditions of 25°C and 2000rpm stirring, dissolve 5g of polyethersulfone PES in 110g of dichloromethane to obtain the first solution, then slowly add 50g of chlorosulfonic acid to the first solution at 25°C to react for 3h to form Mix the solution, then immerse the mixed solution in cold water for 3 hours to produce a precipitate, filter the mixed solution to obtain the precipitate, and wash the precipitate with deionized water several times until the pH becomes 5, then dry the precipitate at 120°C under vacuum for 48 hours to obtain a dry sulfonated Polyethersulfone SPES;

[0029] Take 4g of sulfonated polyethersulfone and 2g of polyacrylonitrile, dissolve them in 50g of dimethylformamide, and prepare a precursor solution with a certain concentration. The precursor solution is aged at 60°C for 12h, stirred for 24h, and left to stand for 24h; then Electrospinning was performed with the precursor solution, the spinning voltage was...

Embodiment 2

[0035] Example 2: at N 2 Atmosphere, under the conditions of 25°C and 2000rpm stirring, dissolve 7g of polyethersulfone PES in 150g of dichloromethane to obtain the first solution, and then slowly add 60g of concentrated sulfuric acid to the first solution at 25°C to react for 4h to form a mixture solution, then the mixed solution was immersed in cold water for 4 hours to produce a precipitate, the mixed solution was filtered to obtain the precipitate, and the precipitate was washed with deionized water for several times until the pH became 5, and then the precipitate was dried at 120°C under vacuum for 48 hours to obtain a dry sulfonated poly Ethersulfone SPES;

[0036] Take 5g of sulfonated polyethersulfone, 1g of polyacrylonitrile and 1.5g of polyether ether ketone, dissolve them in 55g of dimethylacetamide, and prepare a certain concentration of precursor solution. The precursor solution is aged at 65°C for 18h, stirred 28h, stand still for 24h; then use the precursor sol...

Embodiment 3

[0042] Example 3: at N 2 Atmosphere, under the conditions of 25°C and 2000rpm stirring, dissolve 10g polyethersulfone PES in 200g methylene chloride to obtain the first solution, then slowly add 100g chlorosulfonic acid to the first solution at 25°C to react for 5h to form Mix the solution, then immerse the mixed solution in cold water for 5 hours to produce a precipitate, filter the mixed solution to obtain the precipitate, and wash the precipitate with deionized water several times until the pH becomes 5, then dry the precipitate at 120°C for 54 hours under vacuum to obtain a dry sulfonated Polyethersulfone SPES;

[0043] Take 4g of sulfonated polyethersulfone and 1.8g of polyimide, dissolve them in 45g of dimethyl sulfoxide, and prepare a certain concentration of precursor solution. The precursor solution is aged at 70°C for 20h, stirred for 30h, and left standing for 30h ; Then use the precursor solution to carry out electrospinning, set the spinning voltage to 20KV, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com