Method for removing peculiar smell of hot-processed watermelon juice and watermelon juice beverage

A technology of watermelon juice and heat processing, applied in the field of food science, can solve the problems of hindering the development of watermelon juice industry, hot odor, passivation of watermelon juice, etc., and achieve the effect of improving flavor, reducing the concentration of odor components, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for removing the peculiar smell of heat-processed watermelon juice, wherein the method includes:

[0051] (1) Take a bag of 100mL freshly squeezed watermelon juice and heat it in a 70°C water bath for 20 minutes to obtain heat-processed watermelon juice;

[0052] (2) Add xanthan gum in the watermelon juice after thermal processing, fully shake, ultrasonic, stir to make xanthan gum dissolve in the watermelon juice after thermal processing; Wherein, the quality of the watermelon juice after thermal processing is On a 100% basis, the addition of the xanthan gum is 0.2%;

[0053] (3) adding β-cyclodextrin to the heat-processed watermelon juice dissolved with xanthan gum, fully shaking to dissolve the β-cyclodextrin in the heat-processed watermelon juice dissolved with xanthan gum; Wherein, the mass of the watermelon juice after thermal processing is calculated as 100%, and the added amount of the β-cyclodextrin is 0.2%;

[0054] (4) Add c...

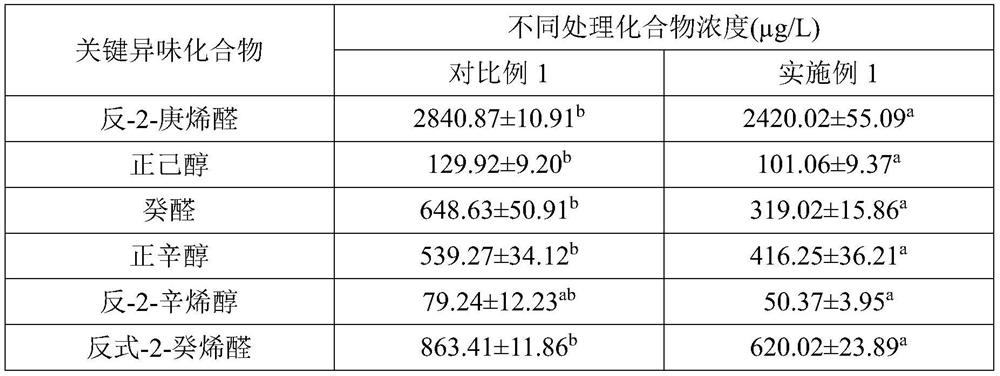

experiment example 1

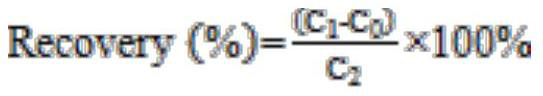

[0061] The watermelon juice drinks of Example 1 and Comparative Example 1 were respectively carried out to measure the concentration of peculiar smell components, specifically in the following manner:

[0062] 1. Perform solid phase microextraction (SPME) on the sample to be tested:

[0063] Accurately measure 10mL of the sample to be tested and place it in a 40mL clean and odorless headspace vial, then add 1μL of 2-methyl-3-heptanone into the headspace vial as an internal standard (concentration: 0.816μg / μL); tighten Put the headspace bottle in the water bath after the bottle stopper of the headspace bottle, and set 40°C as the adsorption temperature; after the system is stable and balanced for 20 minutes, insert the manual injection handle with fiber coating, wherein the fiber coating is in the It has been aged at 250°C for half an hour before use; push out the fiber coating and perform 40min adsorption; after the adsorption is completed, insert the extraction head into the ...

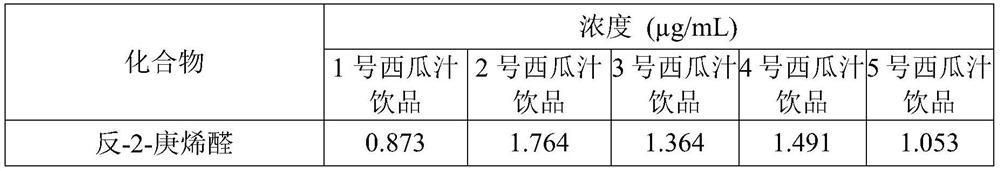

experiment example 2

[0082] The present embodiment compares 5 parts of watermelon juice drinks, wherein,

[0083] 5 groups of watermelon juice drinks are prepared in the following ways:

[0084] (1) Take five bags of freshly squeezed watermelon juice (each bag of watermelon juice is 100mL), heat it in a 70°C water bath for 20 minutes, and obtain five parts of watermelon juice after heat processing, which are named as No. 1 watermelon juice after heat processing, Watermelon juice after No. 2 thermal processing, watermelon juice after No. 3 thermal processing, watermelon juice after No. 4 thermal processing, and watermelon juice after No. 5 thermal processing;

[0085] (2) Add xanthan gum to No. 1 watermelon juice after thermal processing, fully shake, ultrasonic, and stir to make xanthan gum dissolve in the watermelon juice after thermal processing; wherein, the watermelon juice after thermal processing The mass is 100% and the added amount of xanthan gum is 0.19%;

[0086] Add xanthan gum to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com