Supported heteropolyacid catalyst, preparation method and application of supported heteropolyacid catalyst in preparation of convallaria majalis pyrane

A technology of heteropolyacids and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as destruction, reduced selectivity, and unfavorable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of supported heteropolyacid catalyst 1:

[0074] 1) Weigh 150g of KH-560 (γ-glycidyl etheroxypropyltrimethoxysilane) to prepare a 15wt% aqueous solution, add 112.5g of aluminum hydroxide powder (10-50nm) to the solution, and rotate at room temperature at 1100rpm / min fully stirred for 15 minutes, then transferred to the evaporator for evaporative dehydration, after removing 55wt% of the total water, added 9g of polyvinyl alcohol and methyl cellulose, raised the temperature to 75°C, stirred at 1100rpm / min for 15min, and stirred evenly. Shaped into a spherical shape, dried at 120°C to constant weight, transferred to a muffle furnace, and roasted at 750°C for 5 hours in a nitrogen atmosphere to obtain SiO 2 -Al 2 O 3 Composite carrier, the particle size is 4mm.

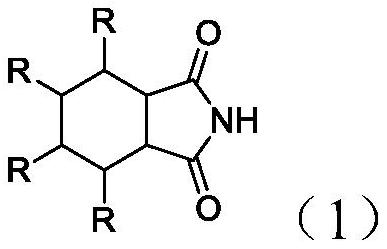

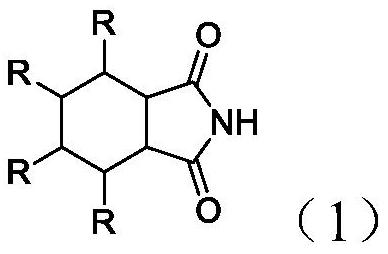

[0075] 2) Weigh 30g of phthalimide derivative 2 with an acidic group, dissolve it in 180g of ethyl acetate, and then add SiO 2 -Al 2 O 3 Composite carrier 105g, fully stirred, refluxed and dehydr...

Embodiment 2

[0078] Preparation of supported heteropolyacid catalyst 2:

[0079] 1) Weigh 150g of tetraethoxysilane to prepare a 10wt% aqueous solution, add 90g of aluminum hydroxide powder (10-50nm) to the solution, stir at room temperature at 500rpm / min for 5min, then transfer to an evaporator for evaporation and dehydration After removing 40wt% of the total water, add 7.5g of methyl cellulose, heat up to 60°C, stir at 500rpm / min for 25min, after stirring evenly, shape and granulate into a spherical shape, dry at 100°C to constant weight, and transfer to In a muffle furnace, calcined at 600°C for 3 hours under a nitrogen atmosphere to obtain SiO 2 -Al 2 O 3 Composite carrier, the particle size is 2mm.

[0080] 2) Weigh 30g of phthalimide derivative 2 with an acidic group, dissolve it in 570g of ethyl acetate, and then add SiO 2 -Al 2 O 3 Composite carrier 150g, fully stirred, refluxed and dehydrated at 70°C for 5h, then transferred the solution after the reflux reaction to an evapo...

Embodiment 3

[0083] Preparation of supported heteropolyacid catalyst 3:

[0084] 1) Weigh 200g of KH-560 (γ-glycidyl etheroxypropyltrimethoxysilane) to prepare a 20wt% aqueous solution, add 180g of aluminum hydroxide powder (10-50nm) to the solution, and rotate at room temperature at 1500rpm / min Fully stir for 20 minutes, then transfer to the evaporator for evaporative dehydration, remove 70wt% of the total water, add 40g of polyvinyl alcohol, heat up to 90°C, stir at 1500rpm / min for 20min, after stirring evenly, shape and granulate into a spherical shape , dried at 150°C to constant weight, transferred to a muffle furnace, and calcined at 900°C for 12h under a nitrogen atmosphere to obtain SiO 2 -Al 2 O 3 Composite carrier, the particle size is 6mm.

[0085] 2) Weigh 30g of phthalimide derivative 3 with an acidic group, dissolve it in 120g of ethyl acetate, and then add SiO 2 -Al 2 O 3 Composite carrier 60g, fully stirred, refluxed and dehydrated at 140°C for 10h, then transferred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com