Preparation method of high-magnetic-loss alloy absorbent

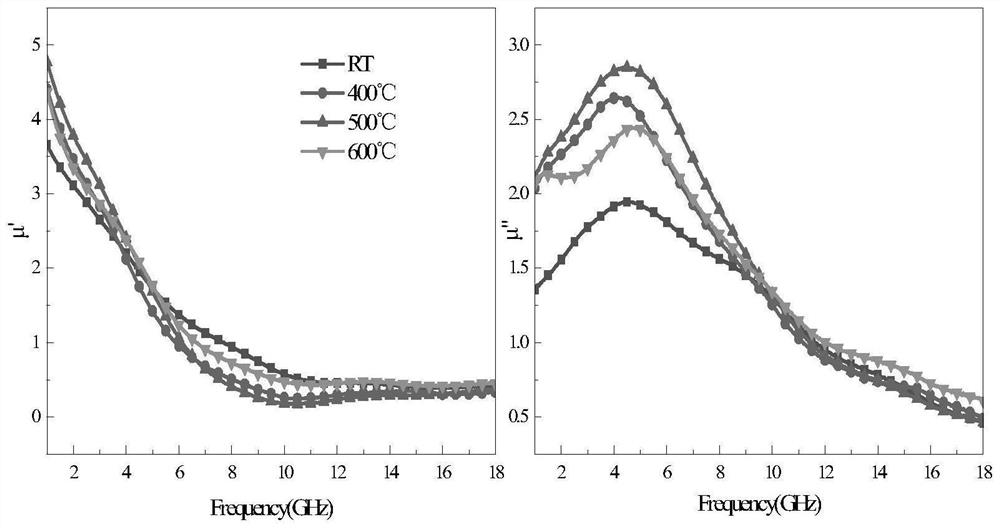

An absorber and alloy technology, applied in the field of wave-absorbing materials, can solve the problem that the absorber is difficult to meet the P-band absorber, and achieve the effect of improving magnetic permeability, promoting magnetic moment precession, and improving magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In view of this, the present invention provides a method of preparing a high magnetic loss consumption absorbent.

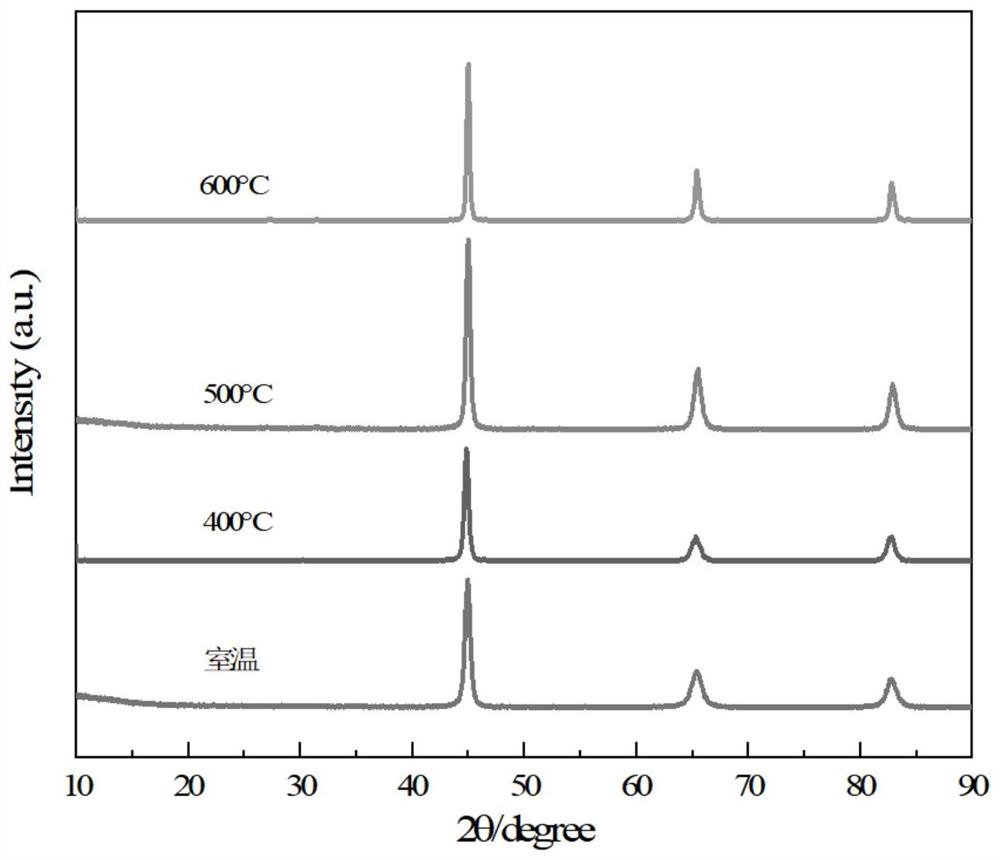

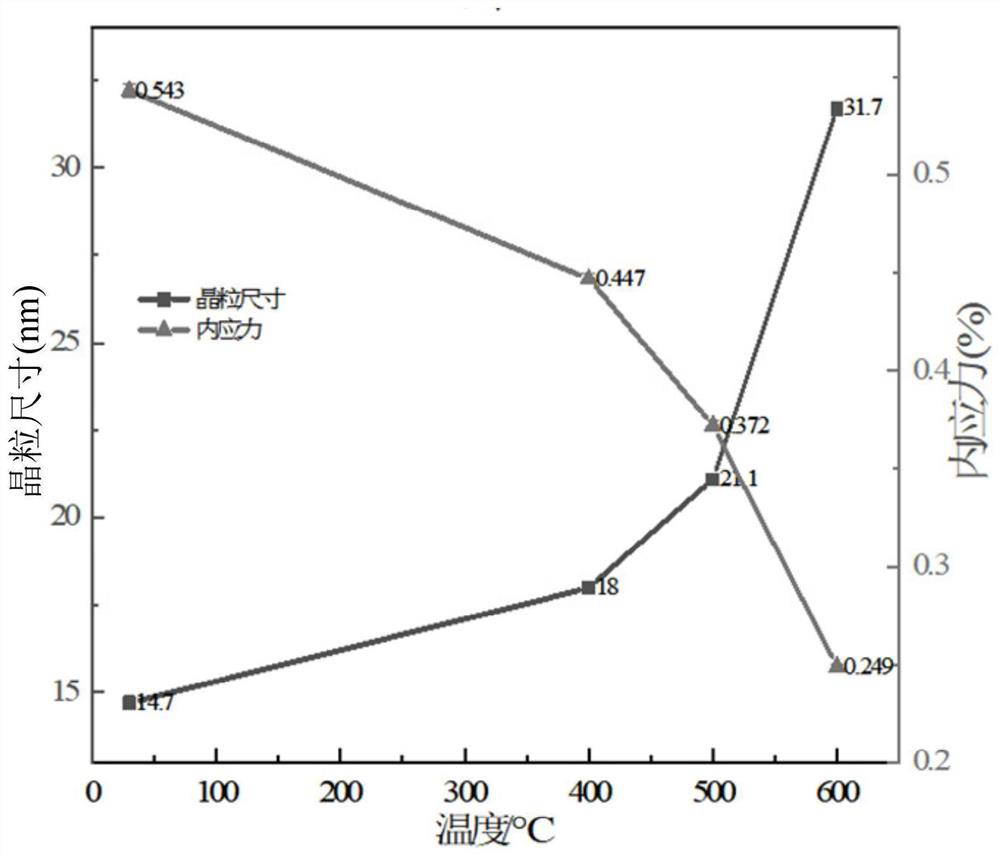

[0032] Please refer to figure 1 The preparation method of the high-magnetic exhaust gas consumption absorbent includes the following steps:

[0033] Step S10, the raw material powder is wet ball milling treatment to make the material sheet shape.

[0034] In this embodiment, the material powder is wet, and the material is sheet-shaped, thereby increasing the complex magnetic permeability of the absorbent.

[0035] Wherein, the raw material powder comprises a FESICR alloy and / or a FESICR base alloy. It will be appreciated that the FESICR base alloy refers to a variety of alloy powders that are FESICR-substrates. At the same time, the applicant found that when the selected raw material powder is a spherical shape having a particle diameter of no less than 2 μm, the absorbent performance obtained after treatment of the present invention is better.

[0036] When...

Embodiment 1

[0058] Weigh 10kg of FESICR powder; 40 kg of zirconia balls, and weigh 20 kg of acetone again. The zirconia ball, acetone, and the FESICR powder were poured into the stain, and the set frequency was 40 Hz, the aging time was 15 h, and the aging was completed after drying.

[0059] The dried Fesicr alloy was placed in a crucible, and the vacuum furnace was placed in a vacuum furnace, and the yield rate was 7.5 ° C / min, and the temperature was held at 400 ° C for 1 h, and then naturally cooled to room temperature.

[0060] The resulting particles and paraffin were mixed evenly, and in a cylindrical container with stirred lever and heated, two-piece magnets were placed outside the container, and the two magnets were in the container. Relative settings. The adjustment heating temperature was 100 ° C, the rotational speed was 100 to 200 rpm, and stirred after 10min, and then removed, the composite material in which the composite was 7 mm was pressed, and the inner diameter of 3 mm wa...

Embodiment 2

[0062] Example 2 and Example 1 were only 500 ° C for the first embodiment and Example 1 as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com