Single-head hydraulic valve grinding machine control system

A control system and a grinding machine technology, applied in the field of grinding machines, can solve problems such as unfavorable staff cleaning, environmental impact, etc., and achieve the effect of enhancing the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

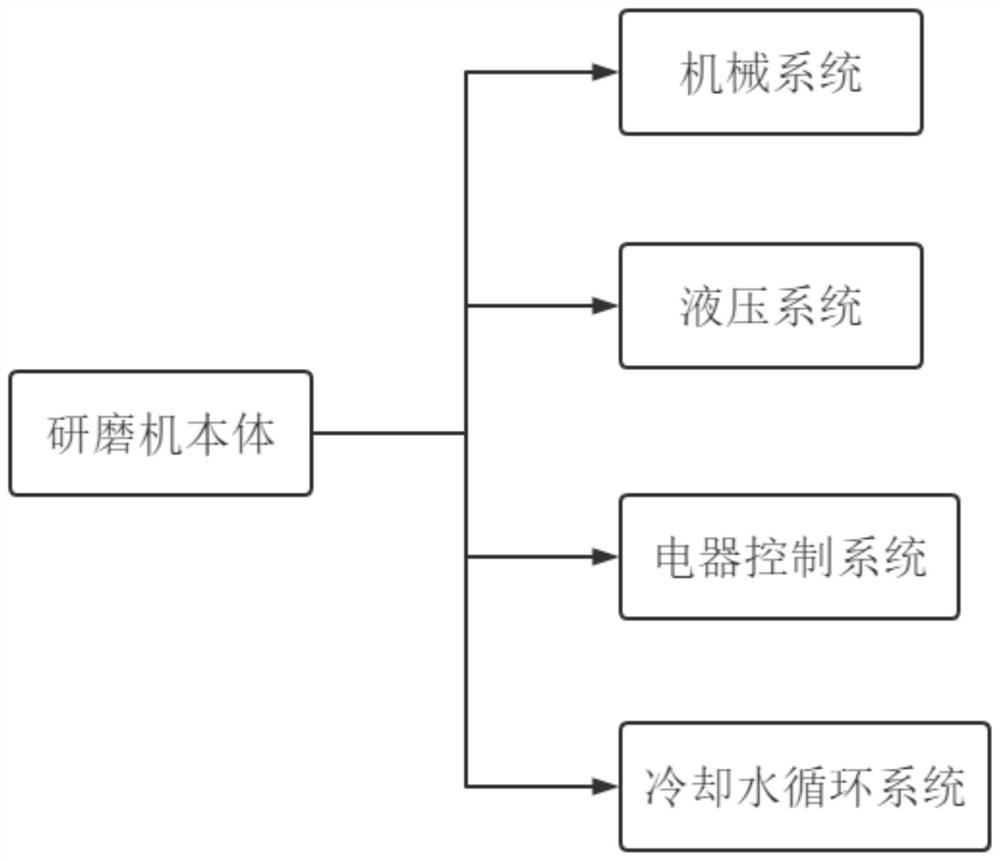

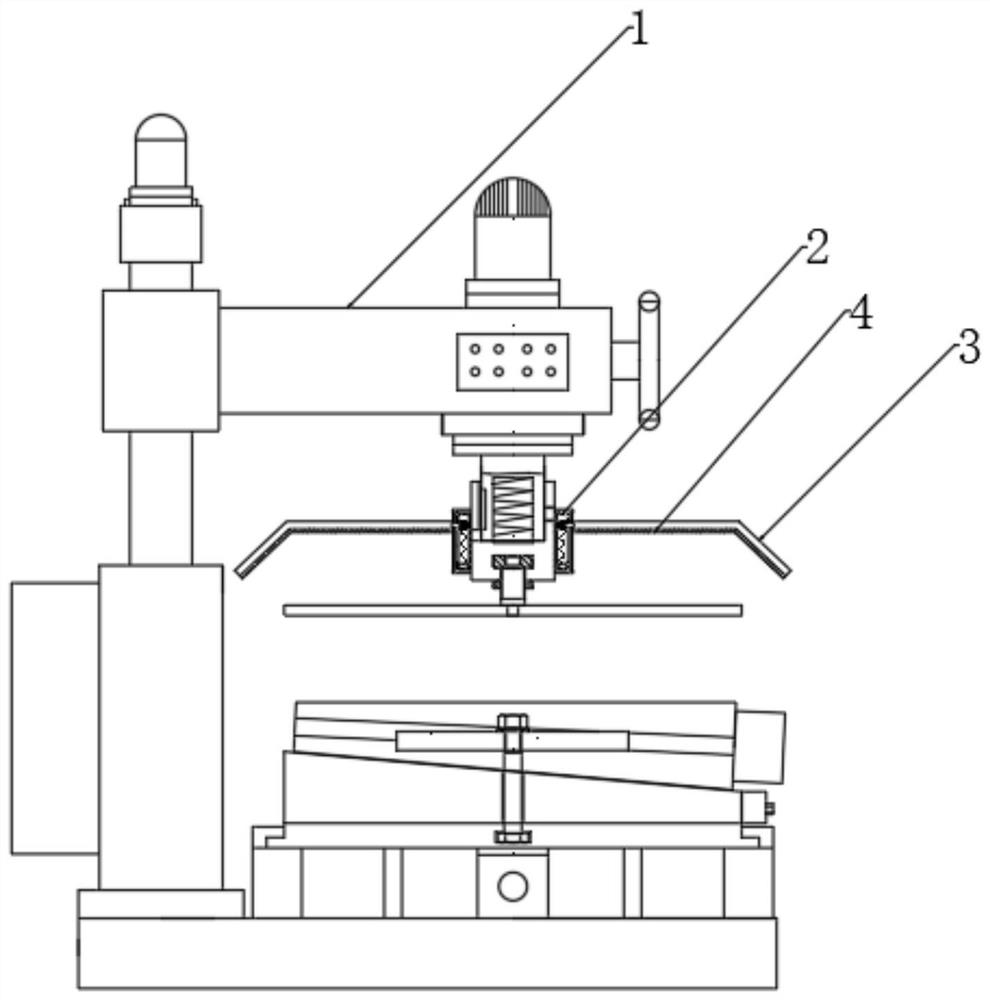

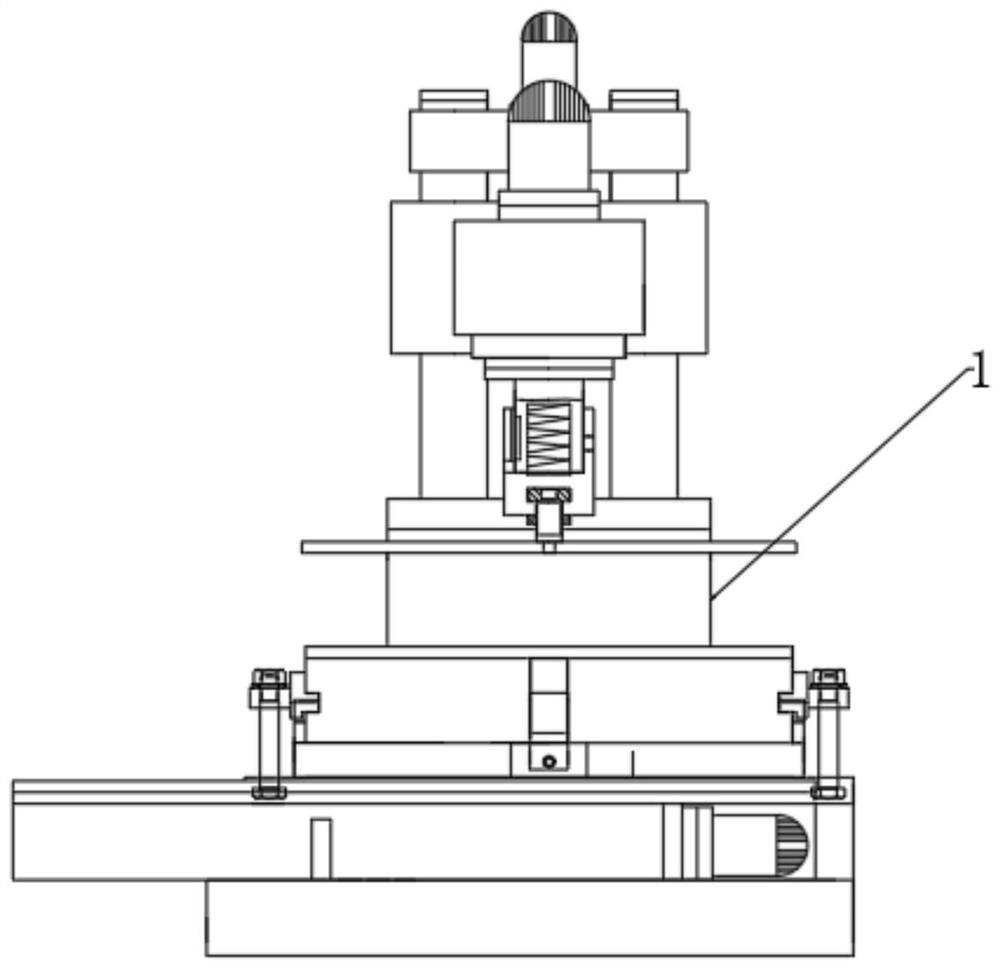

[0041] see figure 1 , a single-head hydraulic valve grinding machine control system, including a grinding machine body 1, a mechanical system 101 is provided in the grinding machine body 1, a hydraulic system 102 is provided in the grinding machine body 1, and an electrical appliance is electrically connected to the grinding machine body 1 The control system 103, the electrical control system 103 is electrically connected with the mechanical system 101, the grinding machine body 1 is provided with a cooling water circulation system 104, the electrical control system 103 is electrically connected with the cooling water circulation system 104, and the electrical control system 103 can be used to drive the machine The system 101 cooperates with the hydraulic system 102 to clamp the valve parts to realize the work of the grinder body 1, so that it can be subjected to rough grinding and fine grinding. At the same time, the cooling water circulation system 104 plays the role of cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com