Preparation method of composite wave-absorbing material and composite wave-absorbing material

A wave-absorbing material and composite technology, applied in the field of wave-absorbing materials, can solve problems such as poor effect of wave-absorbing materials, narrow absorption frequency band, poor thermal stability, etc., to improve thermal stability and oxidation resistance, and improve impedance matching characteristics, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In some embodiments of the present application, the preparation method of the composite absorbing material includes:

[0036] Step S1, dispersing the flaky graphene oxide in an aqueous solution of hexamethylenetetramine to obtain a first dispersion;

[0037] Step S2, dispersing the soluble cobalt salt and the soluble nickel salt into the first dispersion to obtain a second dispersion;

[0038] In step S3, a reducing agent is added to the second dispersion liquid, and the soluble cobalt salt, soluble nickel salt and graphene oxide are reduced by the reducing agent to obtain a composite wave-absorbing material. The method of step-by-step dispersion can improve the uniformity of mixing among the components. Firstly, the flaky graphene oxide is dispersed in the aqueous solution of cyclohexamethylenetetramine to obtain the first dispersion liquid, which can make the cyclohexamethylene tetramine Hexamethylenetetramine enters between the layers of flaky graphene oxide in adva...

Embodiment 1

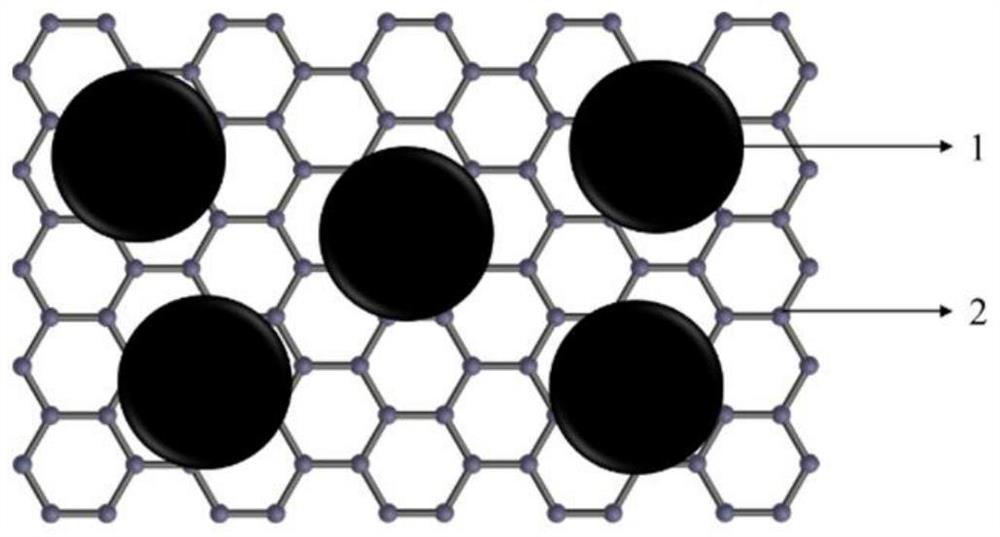

[0070] This embodiment provides a composite absorbing material, the structure of which is as follows figure 1 As shown, the composite absorbing material includes reduced graphene oxide and Co magnetic micro-nano particles and Ni magnetic Wiener particles loaded on the reduced graphene oxide, and its specific preparation method is as follows:

[0071] (1) Graphite oxide is prepared by the Hummers chemical oxidation method, the obtained graphite oxide and distilled water are configured into an aqueous solution, and the power is 150W, the frequency is 53Hz, and ultrasonic stripping is carried out for 1-2 hours to obtain flaky graphene oxide;

[0072] (2) 0.6 g of hexamethylenetetramine (HMT) was added to 40 mL of deionized water, and magnetically stirred at 60° C. for 30 minutes to obtain an aqueous solution of hexamethylenetetramine;

[0073] (3) Add 50 mg of flaky graphene oxide to the aqueous solution of hexamethylenetetramine, stir it for 10 minutes and mix it uniformly to fo...

Embodiment 2

[0076] This embodiment provides a composite wave-absorbing material whose structure is the same as the composite wave-absorbing material provided in Example 1, and its specific preparation method is as follows:

[0077] (1) Graphite oxide is prepared by Hummers chemical oxidation method, the graphite oxide obtained and distilled water are configured into an aqueous solution, and the power is 150W, and the frequency is 53Hz, and ultrasonic stripping is carried out for 1-2 hours to obtain flaky graphene oxide ( GO);

[0078] (2) 0.6 g of hexamethylenetetramine (HMT) was added to 40 mL of deionized water, and magnetically stirred at 80° C. for 30 minutes to obtain an aqueous solution of hexamethylenetetramine;

[0079] (3) Add 60 mg of flaky graphene oxide to the aqueous solution of the above-mentioned cyclohexamethylenetetramine, stir it for 10 minutes and mix it uniformly to form the first dispersion; then add 1.2 mmol CoCl to the first dispersion 2 and 0.4mmolNiCl, and magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com