Water-based reverse gloss oil and preparation method thereof

A water-based, varnish technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow drying of water-based reverse varnish, poor adhesion and poor adhesion of reverse varnish, and reduce VOC emissions. , good adhesion, improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

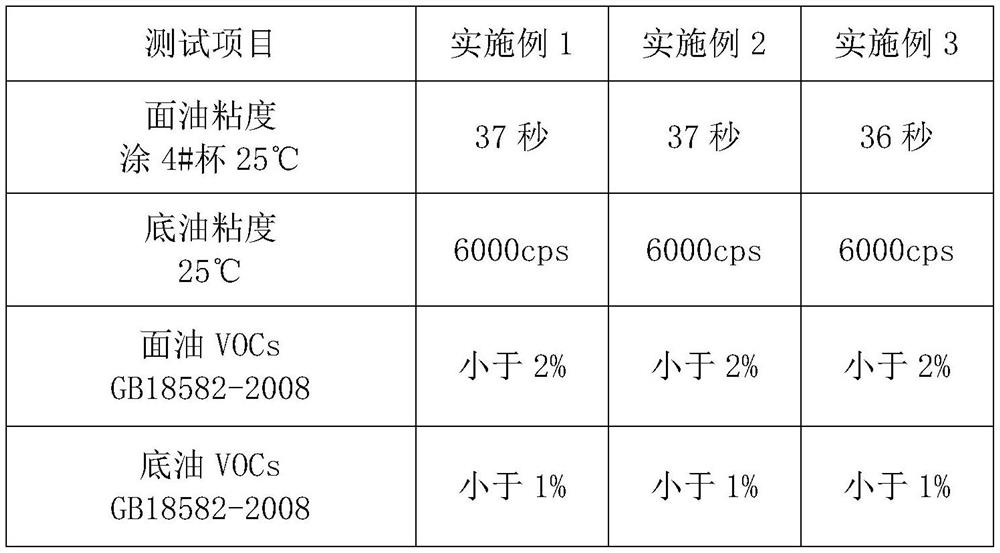

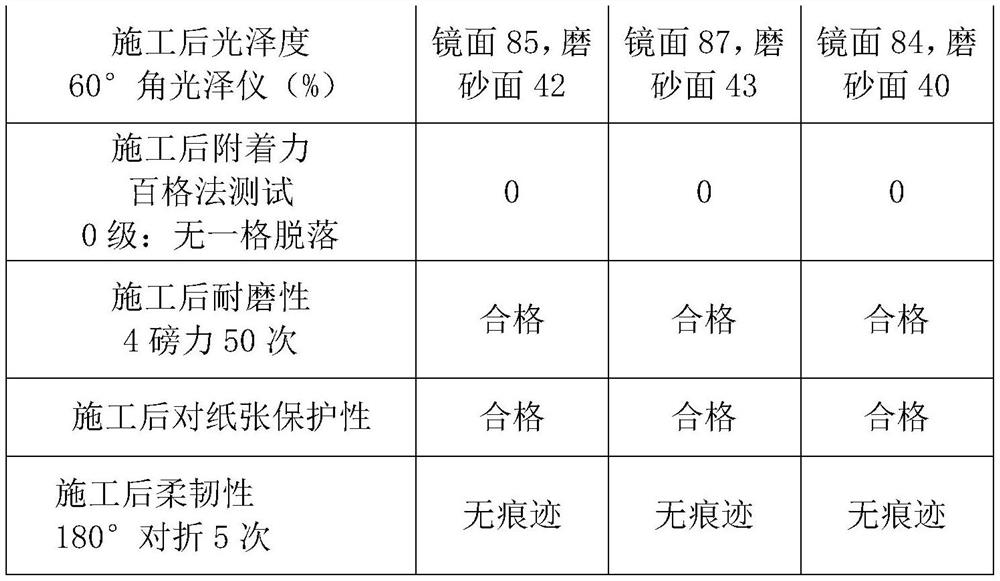

Embodiment 1

[0038] A kind of water-based reverse varnish, comprising water-based base oil and water-based top oil, water-based base oil prepares each raw material by table 1 weight percentage, water-based top oil prepares each raw material by table 2 weight percentage;

[0039] A preparation method of water-based reverse varnish, comprising the following steps:

[0040] (1) Preparation of water-based base oil:

[0041] A1. Put water-based acrylic resin, pure water, propylene glycol, and bentonite into a container, stir and mix evenly, the stirring time is 20 minutes, the stirring speed is 1600 rpm, the stirring condition is 60°C, and the pressure is normal pressure;

[0042] A2. Then add wetting and leveling agent, amine neutralizer and water-based thickener, stir and mix evenly, the stirring time is 16 minutes, the stirring speed is 700 rpm, the stirring condition is 50°C, and the pressure is normal pressure;

[0043] A3. After the stirring is completed, use a three-roll machine to grin...

Embodiment 2

[0049] A kind of water-based reverse varnish, comprising water-based base oil and water-based top oil, water-based base oil prepares each raw material by table 1 weight percentage, water-based top oil prepares each raw material by table 2 weight percentage;

[0050] A preparation method of water-based reverse varnish, comprising the following steps:

[0051] (1) Preparation of water-based base oil:

[0052] A1. Put water-based acrylic resin, pure water, propylene glycol, and bentonite into a container, stir and mix evenly, the stirring time is 25 minutes, the stirring speed is 1500 rpm, the stirring condition is 65°C, and the pressure is normal pressure;

[0053] A2. Then add wetting and leveling agent, amine neutralizer and water-based thickener, stir and mix evenly, the stirring time is 18 minutes, the stirring speed is 500 rpm, the stirring condition is 55°C, and the pressure is normal pressure;

[0054] A3. After the stirring is completed, use a three-roll machine to grind ...

Embodiment 3

[0060] A kind of water-based reverse varnish, comprising water-based base oil and water-based top oil, water-based base oil prepares each raw material by table 1 weight percentage, water-based top oil prepares each raw material by table 2 weight percentage;

[0061] A preparation method of water-based reverse varnish, comprising the following steps:

[0062] (1) Preparation of water-based base oil:

[0063] A1. Put water-based acrylic resin, pure water, propylene glycol, and bentonite into a container, stir and mix evenly, the stirring time is 22 minutes, the stirring speed is 1800 rpm, the stirring condition is 55°C, and the pressure is normal pressure;

[0064] A2. Then add wetting and leveling agent, amine neutralizer and water-based thickener, stir and mix evenly, the stirring time is 15 minutes, the stirring speed is 800 rpm, the stirring condition is 45°C, and the pressure is normal pressure;

[0065] A3. After the stirring is completed, use a three-roll machine to grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com