Random sampling system and method for electroplating wastewater

A random sampling and electroplating wastewater technology, applied in the transmission system, sampling device, digital transmission system, etc., can solve the problems of no measurement and detection, troublesome management and control of electroplating enterprises, no control of discharge, etc., and achieve the effect of convenient production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

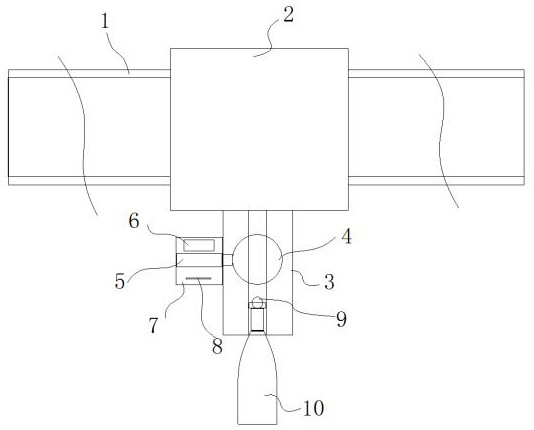

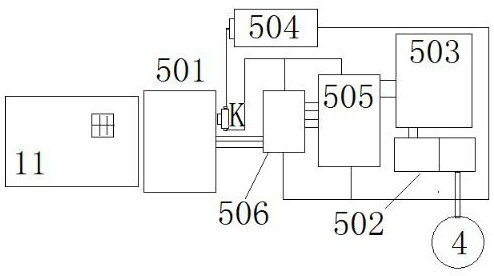

[0021] like figure 1 and figure 2 As shown, a random sampling system for electroplating wastewater includes: three-way fittings 2, wastewater sampling pipeline 3, ball valve 4, ball valve control circuit 5, battery 6, ball valve control unit housing 7, IC bayonet 8, touch valve 9 , Sampling bottle 10; Wherein, three-way pipe fitting 2 is connected on the waste water pipe 1, and the intermediate pass of three-way pipe fitting 2 constitutes waste water sampling pipe 3, waste water sampling pipe 3, ball valve 4 is arranged on waste water sampling pipe 3, ball valve 4 and ball valve The control circuit is connected with 5 shafts, the ball valve control circuit 5 is fixed in the ball valve control unit housing 7, the ball valve control circuit 5 has a micro switch K connected to the battery 6, the ball valve control unit housing 7 has an IC bayonet 8, and an IC card 11 Insert the touch head against the micro switch K through the IC bayonet 8, make the micro switch K conduct, the ...

Embodiment 2

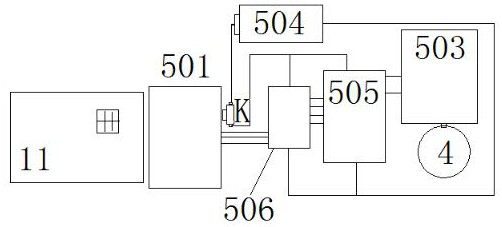

[0025] like figure 1 and image 3As shown, a random sampling system for electroplating wastewater includes: three-way fittings 2, wastewater sampling pipeline 3, ball valve 4, ball valve control circuit 5, battery 6, ball valve control unit housing 7, IC bayonet 8, touch valve 9 , Sampling bottle 10; Wherein, three-way pipe fitting 2 is connected on the waste water pipe 1, and the intermediate pass of three-way pipe fitting 2 constitutes waste water sampling pipe 3, waste water sampling pipe 3, ball valve 4 is arranged on waste water sampling pipe 3, ball valve 4 and ball valve The control circuit is connected with 5 shafts, the ball valve control circuit 5 is fixed in the ball valve control unit housing 7, the ball valve control circuit 5 has a micro switch K connected to the battery 6, the ball valve control unit housing 7 has an IC bayonet 8, and an IC card 11 Insert the touch head against the micro switch K through the IC bayonet 8, make the micro switch K conduct, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com