Natural emulsifier as well as preparation method and application thereof

An emulsifier, a natural technology, used in the field of personal care, can solve the problems of formula color and odor, low content of active ingredients, weak emulsifying ability, etc., and achieve excellent rheology, low production cost, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

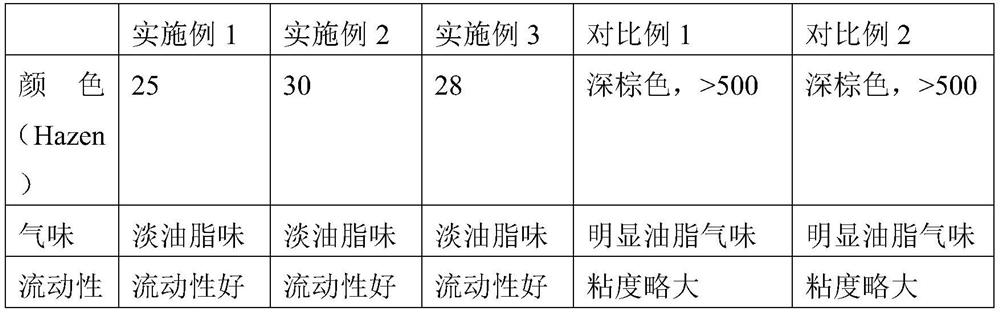

Embodiment 1

[0021] Take 1KG of sunflower oil soap stock and 1200mL of acetone, mix and stir vigorously, let stand to precipitate to obtain acetone insoluble matter, add the above acetone insoluble matter to 500mL of ethanol to dissolve, centrifuge at 3000rpm for 5min to obtain a supernatant, add buffer to the supernatant Solution and phospholipase A2 0.3mL, react at 42°C for 8 hours, add 20% sodium hydroxide solution to make the pH of the solution 7.0 when the measured acid value is >60. Vacuum rotary evaporation at 45°C for 20min, remove the solvent to obtain enzymatic lecithin 62.7 g, add an appropriate amount of glycerin to 100g to obtain an emulsifier.

Embodiment 2

[0023] Take 1KG of sunflower oil soap stock and 1200mL of acetone, mix and stir vigorously, and let stand to precipitate to obtain acetone insoluble matter. Add 500 mL of methanol to dissolve the above-mentioned acetone insoluble matter, and centrifuge at 3000 rpm for 5 min to obtain a supernatant. Add buffer and phospholipase A2 0.3mL to the supernatant, react at 42°C for 8 hours, add 20% sodium hydroxide solution to make the pH of the solution 8.0 when the acid value is >60, and remove the solvent by vacuum rotary evaporation at 45°C for 15min That is, 64.5 g of enzymatically hydrolyzed lecithin was obtained, and an appropriate amount of glycerin was added to 100 g to obtain an emulsifier.

Embodiment 3

[0025] Take 1KG of sunflower oil soap stock and 1200mL of acetone, mix and stir vigorously, and let stand to precipitate to obtain acetone insoluble matter. Add 500 mL of ethanol to dissolve the acetone insoluble matter above, and centrifuge at 3000 rpm for 5 min to obtain a supernatant. Add buffer and phospholipase A2 0.3mL to the supernatant, react at 42°C for 14 hours, add 20% sodium hydroxide solution to make the pH of the solution 7.0 when the acid value is >60, and remove the solvent by rotary evaporation at 45°C for 20min 66.5g of enzymolyzed lecithin was obtained, and an appropriate amount of glycerin was added to 100g to obtain an emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com