Composite ferric salt targeted chelating agent for treating waste incineration fly ash and use method of composite ferric salt targeted chelating agent

A waste incineration fly ash and chelating agent technology, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the risk of secondary dissolution of harmful substances, single stabilization method of chelating agent, and chelation of solidified body The effect is difficult to maintain for a long time, etc., to achieve good heavy metal adsorption capacity, alleviate the phenomenon of frost return, and alleviate the effect of pan-alkaline phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

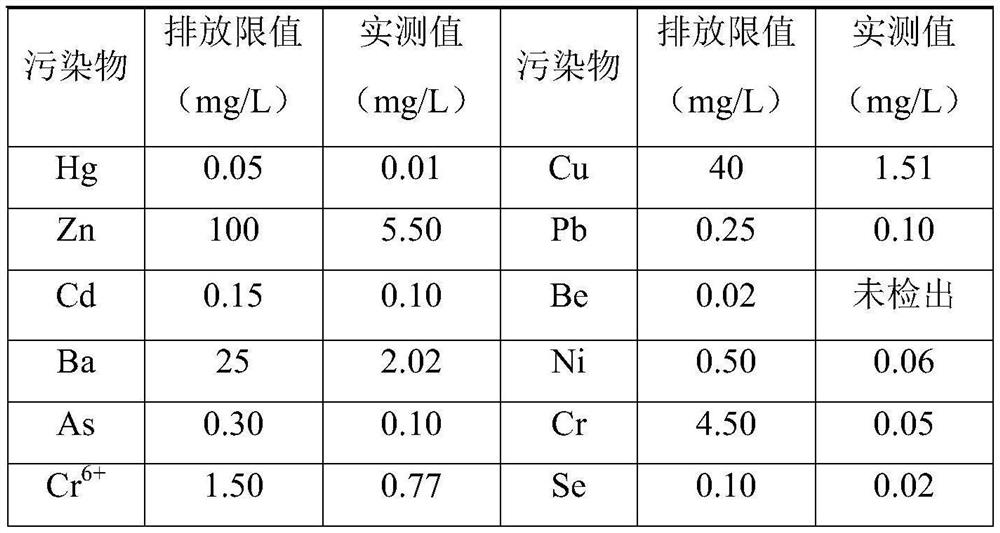

Examples

Embodiment 1

[0032] A compound iron salt targeting chelating agent for treating waste incineration fly ash comprises A component and B component, wherein A component is ferric sulfate and ferrous sulfate, and B component is goethite.

[0033] In this embodiment, the mass ratio of ferric sulfate to ferrous sulfate is 11:9, and the mass ratio of ferric sulfate to goethite is 11:4.

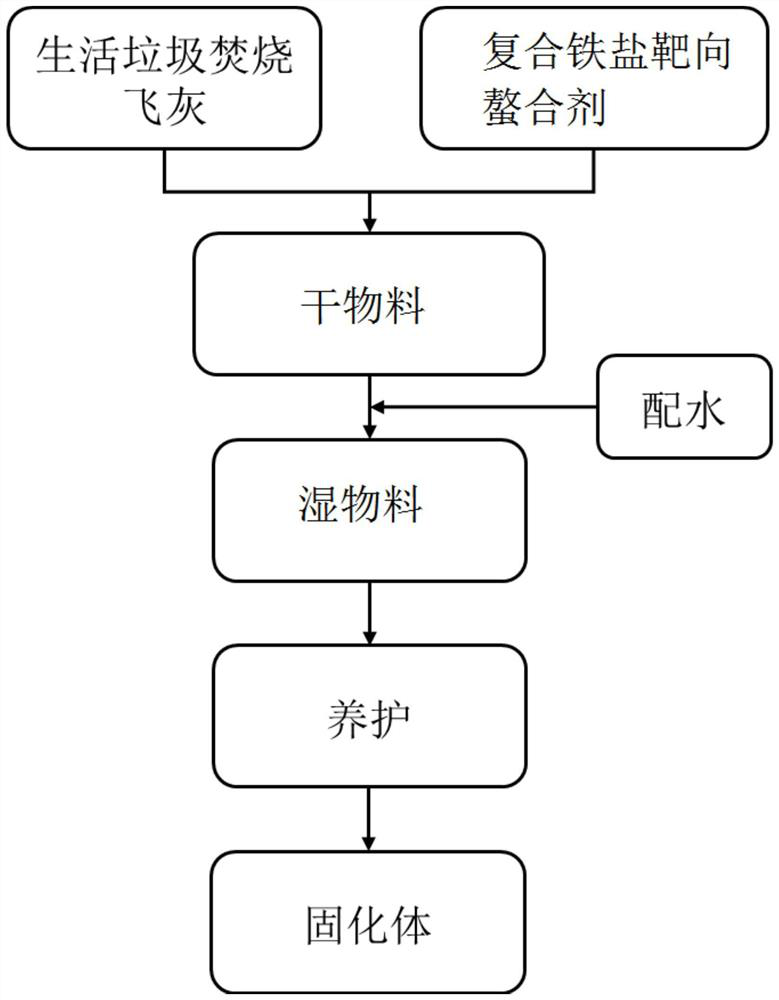

[0034] A kind of compound iron salt targeting chelating agent in the above-mentioned present embodiment is used for the use method of processing waste incineration fly ash, such as figure 1 shown, including the following steps:

[0035] (1) Put 2000g of waste incineration fly ash and 240g of complex iron salt targeting chelating agent into the dry material mixer, mix them, and stir for 10min at a speed of 15rpm to 30rpm (stir for 5min at a speed of 15rpm to 30rpm). 15 minutes is acceptable, which is beneficial to ensure the uniformity of the mixing material, and while ensuring the uniformity, it also ensures the...

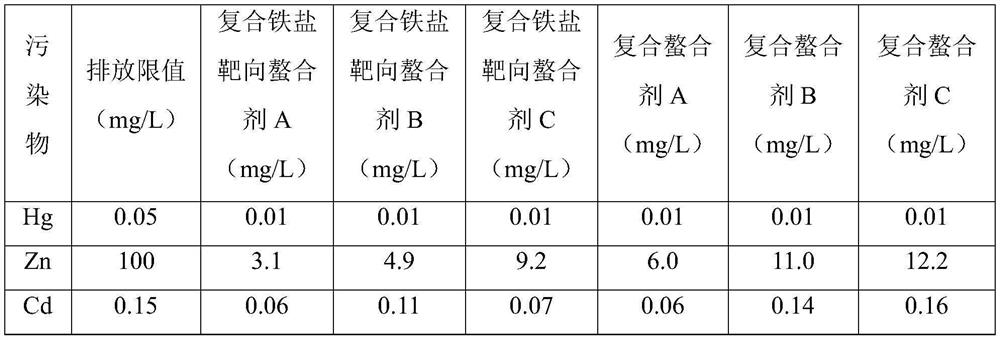

Embodiment 2

[0050] A compound iron salt targeted chelating agent for treating waste incineration fly ash, comprising A component and B component, wherein A component is ferric sulfate and ferrous sulfate, and B component is goethite and ferrihydrite .

[0051] In this embodiment, the mass ratio of ferric sulfate to ferrous sulfate is 9:5, and the mass ratio of ferric sulfate to component B (goethite and ferrihydrite) is 9:2.

[0052] A kind of compound iron salt targeting chelating agent in the above-mentioned present embodiment is used for the use method of processing waste incineration fly ash, such as figure 1 shown, including the following steps:

[0053] (1) Put 2000g of waste incineration fly ash, 160g of complex iron salt targeting chelating agent, 200g of curing agent (composite Portland cement) and 40g of stabilizer (sodium lignin sulfate) into the dry material mixer, mix and stir After 10 minutes, dry material was obtained. In this step, the composite iron salt targeting chel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com