Preparation process of chondroitin sulfate chelated calcium with anti-osteoporosis function

A chondroitin sulfate and anti-osteoporosis technology, which is applied to the functions of food ingredients, drug combinations, bone diseases, etc., can solve the problems of no synergistic effect, loss, and reduced calcium absorption rate of chondroitin sulfate chelated calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

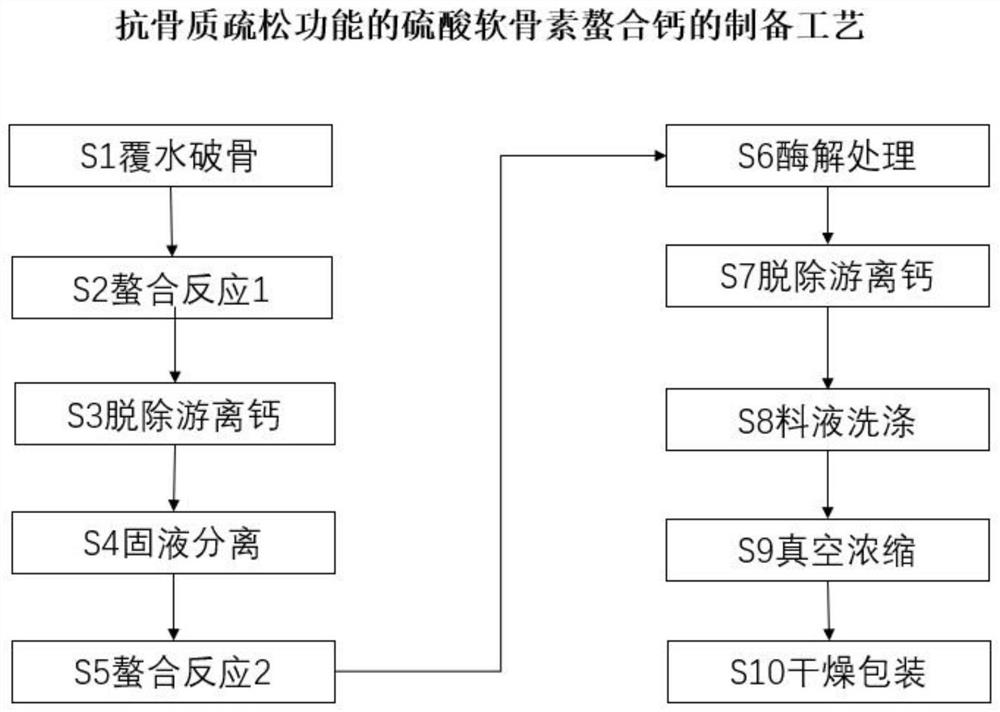

Method used

Image

Examples

Embodiment 2

[0058] Preparation example

Embodiment 3

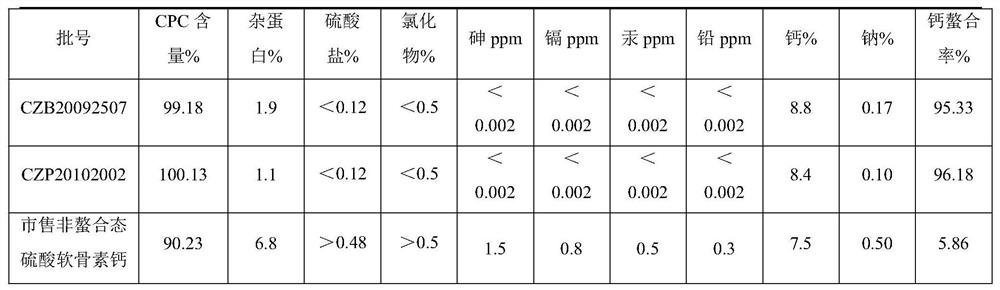

[0072] 3 Test example: The chondroitin sulfate calcium produced by different processes is comprehensively tested, including CPC content, miscellaneous protein content, sulfate content, chloride content, heavy metal content, calcium, and sodium. The following test data are obtained , where the test basis is as follows:

[0073] 3.1USP Pharmacopoeia: CPC content, miscellaneous protein content, sulfate content, chloride content

[0074] 3.2GB5009.268-2016: Arsenic, lead, mercury, cadmium, calcium, sodium

[0075] 3.3 Calcium chelation rate detection method:

[0076]Mix the 3mg / mL calcium chondroitin sulfate sample with 5mM thoroughly, keep it warm at 37°C for 10min, then add 20mM phosphate buffer (pH 7.8) and react at 37°C for 30min, after the reaction, centrifuge at 4000g for 20min to remove the Calcium phosphate precipitates. At this time, the calcium ions in the solution can remain in a dissolved state without being precipitated by phosphate radicals because of the combinat...

experiment example

[0086] 4 Design of animal test models and comparison of results

[0087] 4.1 Establishment and verification of osteoporosis rat model after ovariectomy

[0088] In this study, an osteoporosis model was established through ovariectomy. 50 female rats (weight 210-230g) were given adaptive feeding for 7 days after receiving the animal room. The rats drank distilled water freely and fed standard feed. The animal room was maintained at a constant temperature of 23±1°C, with 12 hours of light and 12 hours of darkness every day, simulating the alternation of day and night.

[0089] The specific operation of modeling the osteoporosis rat model after ovariectomy is as follows:

[0090] 1) Rats were anesthetized by intraperitoneal injection of sodium pentobarbital (dissolved by ultrasonication at 37° C.) at a dose of 25 mg / kg body weight.

[0091] 2) After complete anesthesia, the abdomen of the rat is upward, the limbs and the mouth are fixed on the rat operating board with cotton th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com