Preparation method of phenyl phosphine oxide synergistic graphene-POSS flame-retardant polycarbonate material

A technology of flame retardant polycarbonate and phenyl phosphine oxide, which is applied in the field of polycarbonate flame retardant and can solve the problems of unsatisfactory flame retardant effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

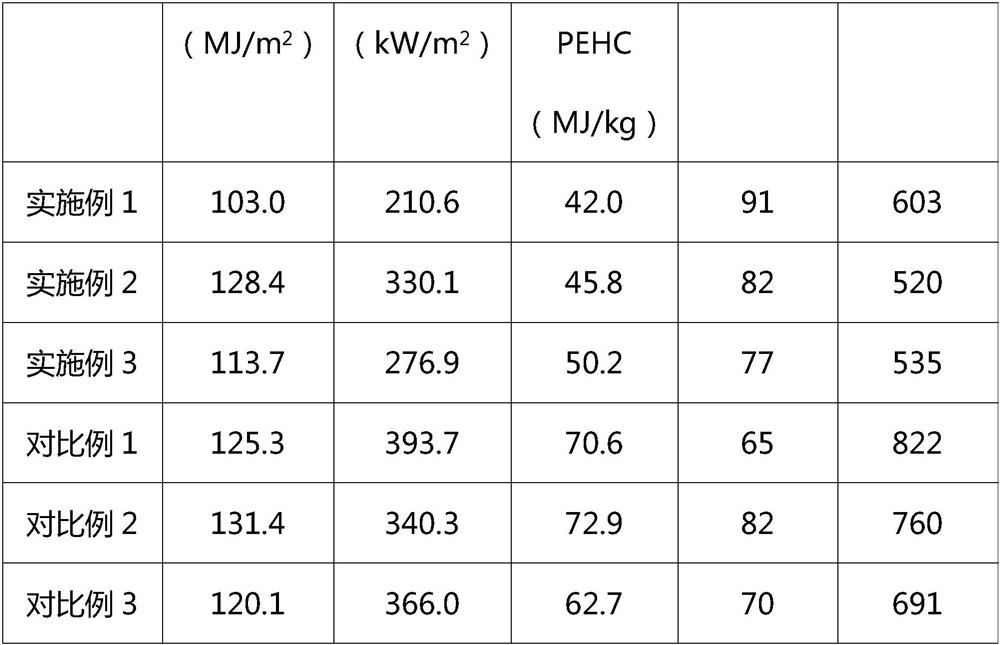

Examples

Embodiment 1

[0035] A kind of preparation method of phenylphosphine oxide cooperative graphene-POSS flame-retardant polycarbonate material, comprises the following steps:

[0036] Step S1, preparation of amino-terminated imidized graphene:

[0037] Place 0.1 g of graphene in 120 mL of H 2 SO 4 and HNO 3 (volume ratio 3: 1), ultrasonication at room temperature for 4h, filtered after dilution, washed with distilled water to neutrality, and vacuum-dried to obtain carboxylated graphene;

[0038] The carboxylated graphene is placed in a flask filled with 3g of 3,3'-diaminodipropylamine, ultrasonicated for 30min at room temperature, and 0.1g of N,N'-dicyclohexylcarbodiimide is added, mixed uniformly, Reflux in an oil bath at 110°C for 48 hours, and the product is ultrasonically removed with absolute ethanol to remove the remaining N,N'-dicyclohexylcarbodiimide and 3,3'-diaminodipropylamine, and the final product is washed several times with distilled water , after drying, obtain amino-termin...

Embodiment 2

[0048] A kind of preparation method of phenylphosphine oxide cooperative graphene-POSS flame-retardant polycarbonate material, comprises the following steps:

[0049] Step S1, preparation of amino-terminated imidized graphene:

[0050] 0.12 g of graphene was placed in 120 mL of H 2 SO 4 and HNO 3(volume ratio 3: 1), ultrasonication at room temperature for 5h, filtered after dilution, washed with distilled water to neutrality, and vacuum-dried to obtain carboxylated graphene;

[0051] The carboxylated graphene is placed in a flask filled with 5g of 3,3'-diaminodipropylamine, ultrasonicated for 60min at room temperature, and 0.12g of N,N'-dicyclohexylcarbodiimide is added, mixed uniformly, Reflux in an oil bath at 150°C for 36 hours, and the product is ultrasonically removed with absolute ethanol to remove the remaining N,N'-dicyclohexylcarbodiimide and 3,3'-diaminodipropylamine, and the final product is washed several times with distilled water , after drying, obtain amino-...

Embodiment 3

[0061] A kind of preparation method of phenylphosphine oxide cooperative graphene-POSS flame-retardant polycarbonate material, comprises the following steps:

[0062] Step S1, preparation of amino-terminated imidized graphene:

[0063] 0.05 g of graphene was placed in 120 mL of H 2 SO 4 and HNO 3 (volume ratio 3: 1), ultrasonication at room temperature for 2h, filtered after dilution, washed with distilled water to neutrality, and vacuum-dried to obtain carboxylated graphene;

[0064] The carboxylated graphene is placed in a flask filled with 1g of 3,3'-diaminodipropylamine, ultrasonicated at room temperature for 20min, and 0.05g of N,N'-dicyclohexylcarbodiimide is added, mixed uniformly, Reflux in an oil bath at 130°C for 40 hours, and the product is ultrasonicated with absolute ethanol to remove the remaining N,N'-dicyclohexylcarbodiimide and 3,3'-diaminodipropylamine, and the final product is washed several times with distilled water , after drying, obtain amino-termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com