High-performance low-temperature efficient ion composite permeation surface modification method for austenitic stainless steel

A technology for surface modification of austenitic stainless steel, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as high service temperature, low nitriding efficiency, and impact on corrosion resistance, and achieve Enhanced surface hardness, increased hardness, and high nitriding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Cut the 304 stainless steel into a sample with a size of 10mm×10mm×5mm.

[0033] (2) The samples were polished to the mirror surface with 600#~2000# SiC sandpaper in turn, soaked in absolute ethanol and ultrasonically cleaned for 10 minutes to remove surface oil and other impurities, and dried for later use.

[0034] (3) Put the sample into a vacuum nitriding furnace, add TC4 wire around the surface of the sample, specifically: add 200 mg around the surface of each gram of sample, and perform sputter cleaning for 30 minutes first.

[0035] (4) After the sputter cleaning is completed, low-temperature ion nitriding is performed at a given process parameter of 420°C / 4h. The model of the vacuum nitriding furnace is LDMC-8CL, the flow ratio of nitrogen and hydrogen is 1:3, and the total flow of nitrogen and hydrogen mixed gas is 700ml / min;

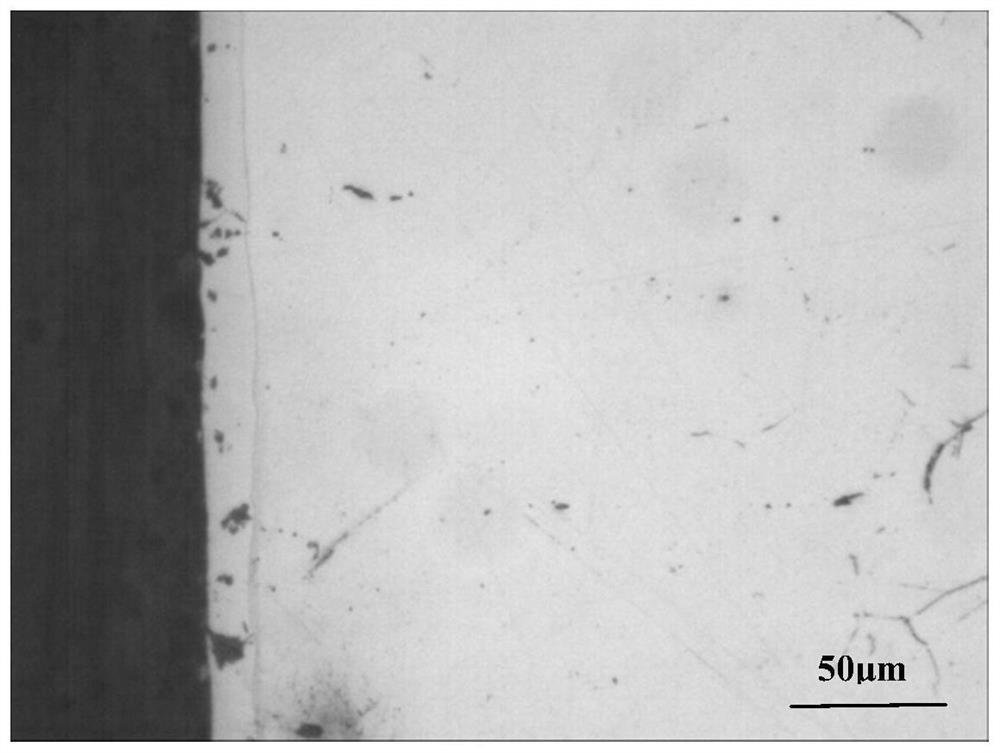

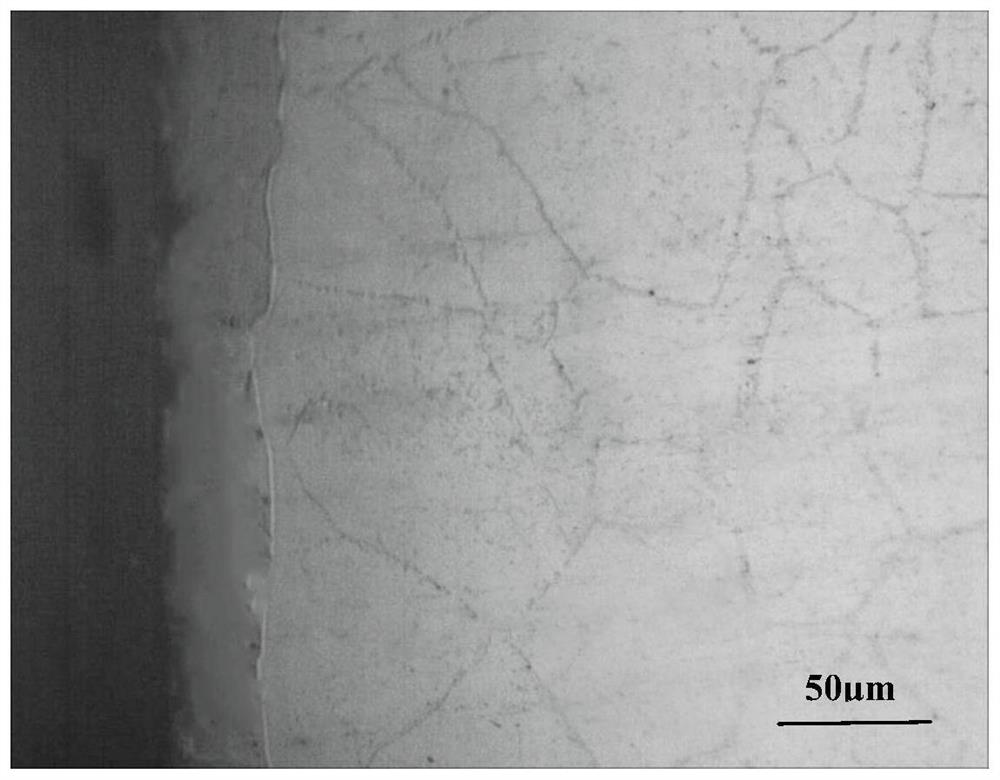

[0036] (5) Take out the sample after the ion composite infiltration treatment, and use an optical metallographic microscope to obs...

Embodiment 2

[0041] (1) Cut the 304 stainless steel into a sample with a size of 10mm×10mm×5mm.

[0042] (2) The samples were polished to the mirror surface with 600#~2000# SiC sandpaper in turn, soaked in absolute ethanol and ultrasonically cleaned for 10 minutes to remove surface oil and other impurities, and dried for later use.

[0043] (3) Put the sample into a vacuum nitriding furnace, add TC4 wire around the surface of the sample, specifically: add 250 mg around the surface of each gram of sample, and first perform sputter cleaning for 30 minutes.

[0044] (4) After the sputter cleaning is completed, low-temperature ion nitriding is performed at a given process parameter of 420°C / 4h. The model of the vacuum nitriding furnace is LDMC-8CL, the flow ratio of nitrogen and hydrogen is 1:3, and the total flow of nitrogen and hydrogen mixed gas is 700ml / min;

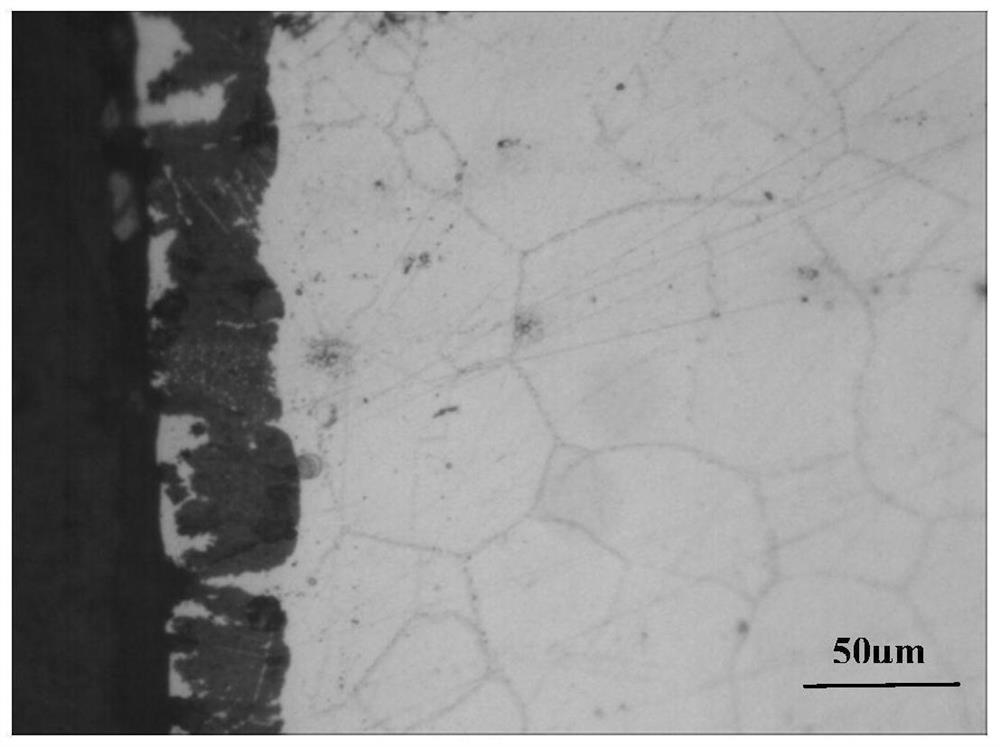

[0045] (5) Take out the sample after the ion composite infiltration treatment, and use an optical metallographic microscope to obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com