Manufacturing method of polyester spunbonded needled non-woven filter material

A filter material and manufacturing method technology, applied in the direction of non-woven fabrics, textiles and papermaking, filament/thread forming, etc., can solve the problems of limited fiber entanglement, large product thickness, low filtration efficiency, etc. The effect of high density and high filtration precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

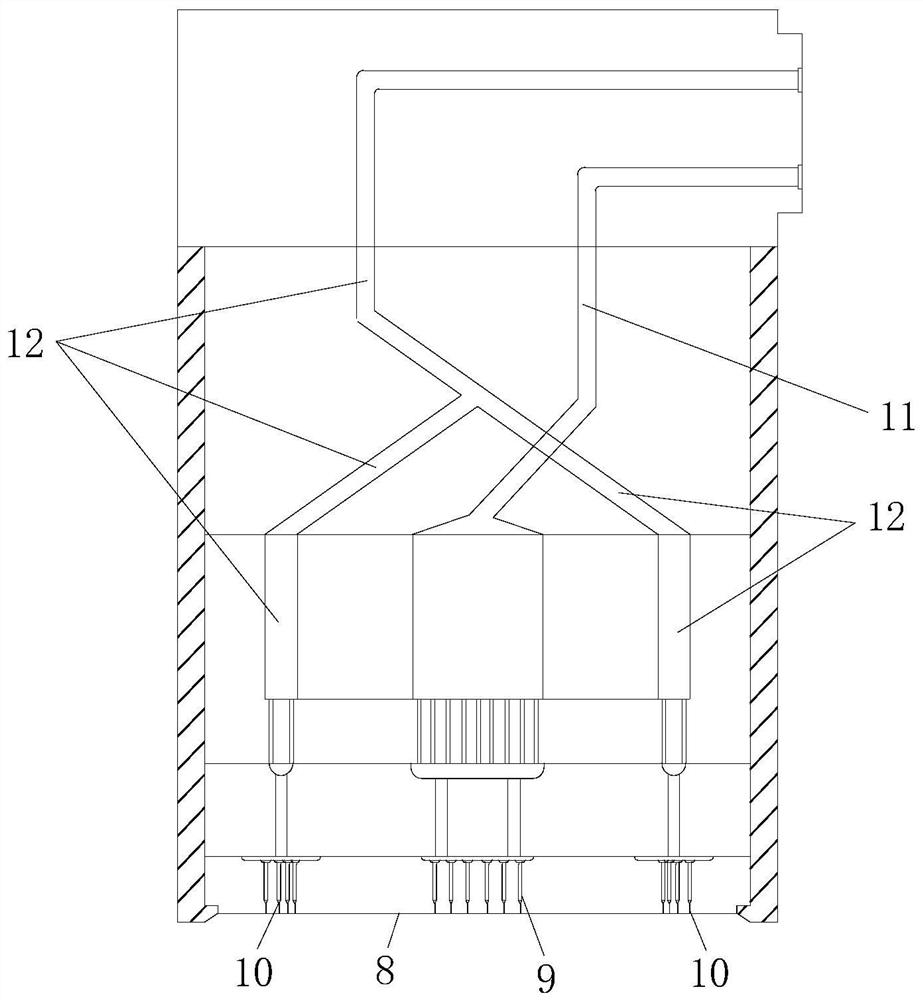

[0046] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

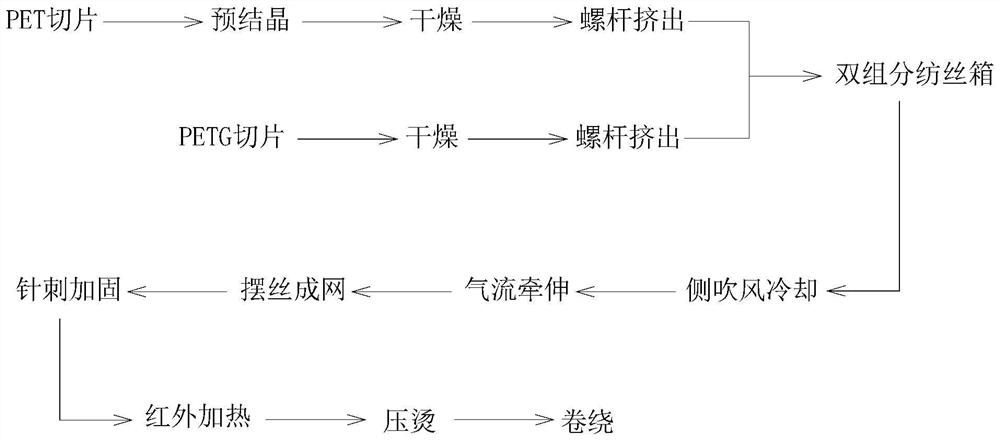

[0047] The manufacture method process flow of the high-density polyester spun-bonded needle-punched nonwoven filter material of the present invention is as follows figure 1 shown.

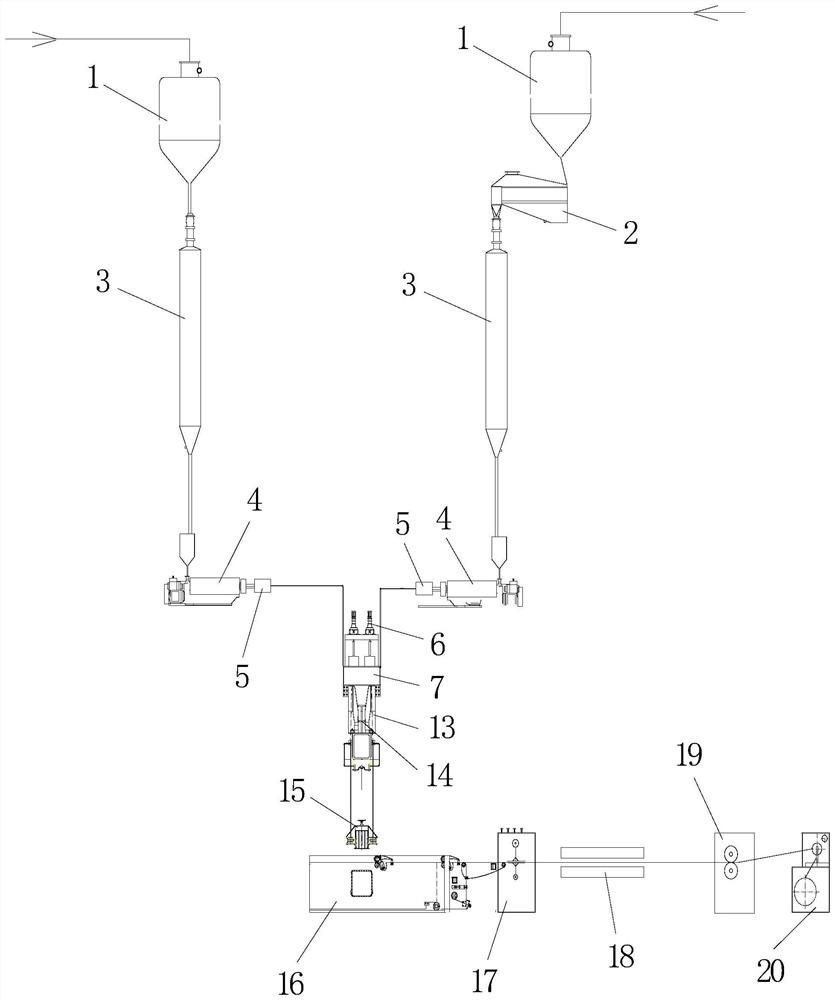

[0048] PET (polyethylene terephthalate) slices are thrown into the silo 1 and conveyed through the rotary valve, and then fall into the pre-crystallizer 2.

[0049] In the pre-crystallizer 2, the PET slices are in a boiling state under the blowing of hot air, and the slices collide with each other to prevent sticking. The slices are heated in the pre-crystallizer 2, the degree of crystallization increases, the water content decreases, and the pre-crystallization temperature is 140-160°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com