Cylindrical high polymer material composite flexible explosion-proof tank and preparation method thereof

A polymer material, cylindrical tank technology, used in blasting, other household appliances, household appliances, etc., can solve the problems of weakening the shock wave damage effect, splashing, inconvenient movement, etc., to achieve complementary material properties, reduce transmission strength, The effect of improving the protection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

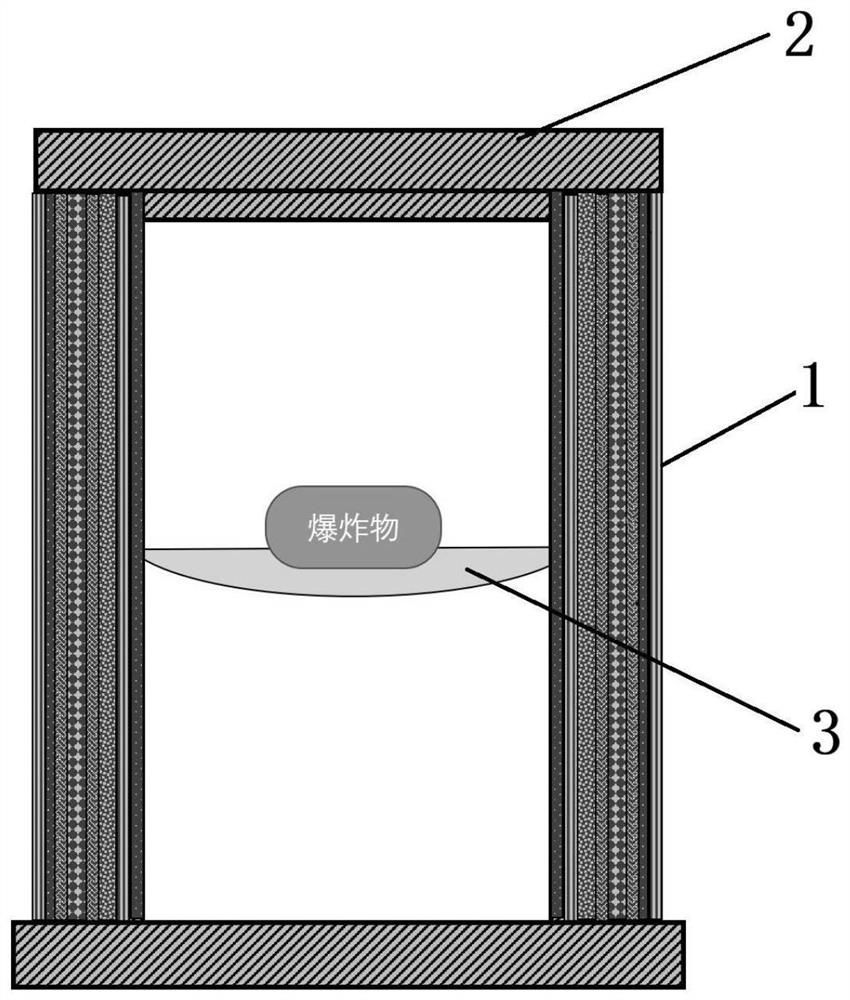

[0042] Embodiment 1: A cylindrical polymer material composite flexible explosion-proof tank, comprising a cylindrical tank body 1, a tank body bag with a handle and a lid 2 covered on the cylindrical tank body 1; the cylindrical tank body The body 1 is provided with a support explosion net 3, and the support explosion net 3 is suspended in the middle of the cylindrical tank body 1. The cylindrical tank 1 includes a first explosion-proof structural unit and a second explosion-proof structural unit arranged sequentially from the inside to the outside, the first explosion-proof structural unit and the second explosion-proof structural unit both include a first flexible explosion-proof layer, a second flexible explosion-proof layer and a third flexible explosion-proof layer; the second flexible explosion-proof layer is arranged between the first flexible explosion-proof layer and the second flexible explosion-proof layer.

Embodiment 2

[0043] Embodiment 2: A cylindrical polymer material composite flexible explosion-proof tank, the cylindrical tank body 1 includes a first explosion-proof structural unit, an explosion-proof structural unit and a second explosion-proof structural unit sequentially arranged from the inside to the outside, the first explosion-proof structural unit Both the structural unit and the second explosion-proof structural unit include a first flexible explosion-proof layer, a second flexible explosion-proof layer and a third flexible explosion-proof layer; the second flexible explosion-proof layer is arranged between the first flexible explosion-proof layer and the second flexible explosion-proof layer between. Among them, the explosion-relief structural unit is composed of a halogen-free flame-retardant polyurethane rigid foam agent. The first flexible explosion-proof layer is a certain number of layers of rubber-impregnated non-woven fabric wound around the cylindrical tank body. The s...

Embodiment 3

[0044] Embodiment 3: A cylindrical polymer material composite flexible explosion-proof tank, comprising a cylindrical tank body 1, a tank body bag with a handle and a lid 2 covered on the cylindrical tank body 1; the cylindrical tank body The body 1 is provided with a support explosion net 3, and the support explosion net 3 is suspended in the middle of the cylindrical tank body 1. The cylindrical tank body 1 includes a first explosion-proof structural unit, an explosion-proof structural unit and a second explosion-proof structural unit arranged sequentially from the inside to the outside, and the first explosion-proof structural unit and the second explosion-proof structural unit both include the first flexible explosion-proof layer 1. A second flexible explosion-proof layer and a third flexible explosion-proof layer; the second flexible explosion-proof layer is arranged between the first flexible explosion-proof layer and the second flexible explosion-proof layer. Among them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com