Method for treating uns-dimethylhydrazine waste gas in combustion of gas fuel and its equipment

A gas fuel and unsymmetrical dimethylhydrazine technology, which is applied in the field of gas fuel combustion to treat unsymmetrical dimethylhydrazine waste gas, can solve problems such as improper concentration control, difficult temperature control, and difficult operation, and achieve low operating costs, thorough treatment, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

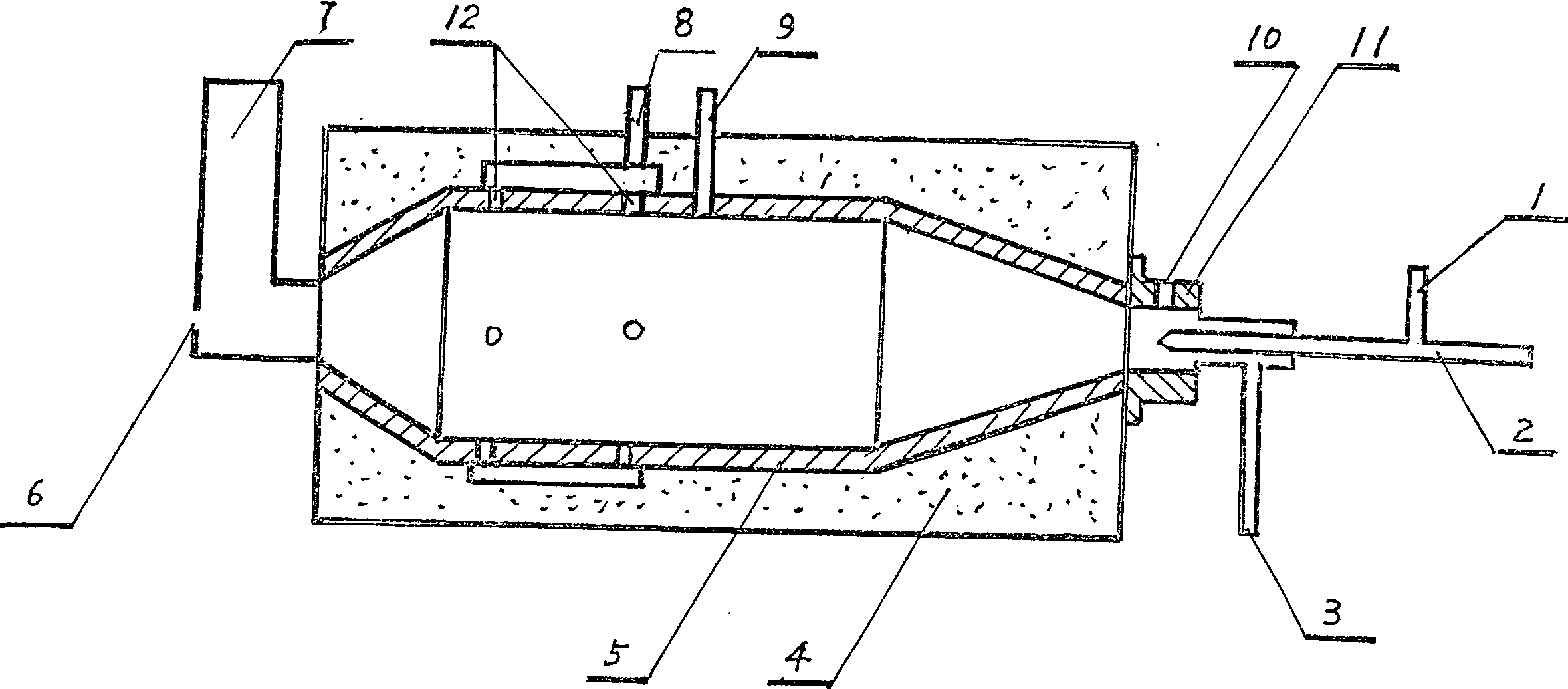

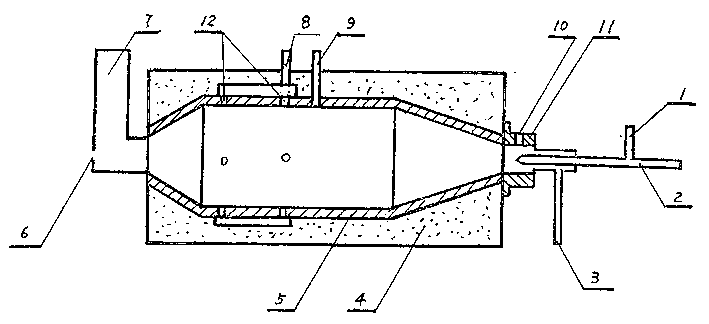

[0023] As shown in the figure, 1 is the exhaust gas inlet, 2 is the gas fuel inlet, 3 is the primary air inlet, 4 is the insulation layer, 5 is the furnace body, 6 is the fire viewing hole, 7 is the exhaust port, and 8 is the secondary air inlet , 9 is a temperature measuring hole, 10 is an ignition hole, 11 is a burner, and 12 is a secondary air distribution hole.

[0024] The burner 11 is installed at the front of the furnace body, and the burner is provided with a primary air inlet 3, a gas fuel inlet 2 and (unsymmetrical dimethylhydrazine) exhaust gas inlet 1, and the gas fuel inlet 2 is connected with (unsymmetrical dimethylhydrazine) exhaust gas inlet 1 , the middle and rear of the furnace body 5 are provided with secondary air distribution holes 12, the temperature measuring hole 9 is located in the middle of the furnace body 5, the exhaust port 7 is located at the rear of the furnace body 5, and the fire viewing hole 6 is located at the exhaust On the mouth 7 and on th...

Embodiment 2

[0028] Other conditions are the same as embodiment 1, just change primary air volume into 10 cubic meters / hour (primary air coefficient is 0.80) pass into content simultaneously and be that 7% unsymmetrical dimethyl hydrazine waste gas 5 cubic meters / hour burn together with methanol cracking gas , the total air coefficient is 2.3, the temperature in the furnace is 840°C, the tail gas is sampled and analyzed, and the residual amount of unsymmetrical dimethylhydrazine in the tail gas is less than 2PPm.

Embodiment 3

[0030] Other conditions are with embodiment 1, just change primary air volume into 22.5 cubic meters / hour (primary air coefficient is 0.92), pass into content simultaneously and be 15% unsymmetrical dimethyl hydrazine waste gas 4.8 cubic meters / hour and methanol cracking gas one Combustion, the total air coefficient is 2.1, the temperature in the furnace is 935°C, the tail gas is sampled and analyzed, and the residual amount of unsymmetrical dimethylhydrazine in the tail gas is less than 2ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com