Low-warping-rate double-layer stacked ceramic system and packaging method

A packaging method and warpage rate technology, applied in coatings, decorative arts, measuring devices, etc., can solve the problems of large volume ratio of structural parts, difficulty in controlling the yield, and bending of ceramic materials, so as to achieve easy control of process parameters and low Warpage rate, the effect of improving system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and specific examples.

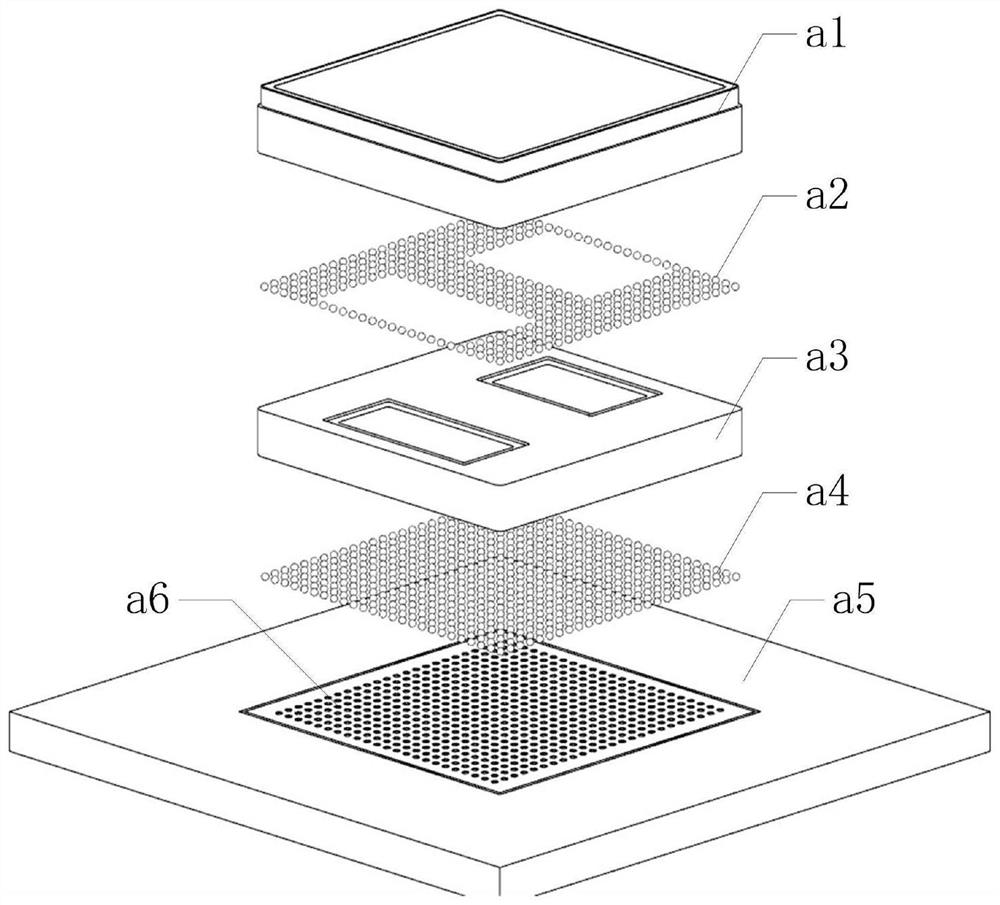

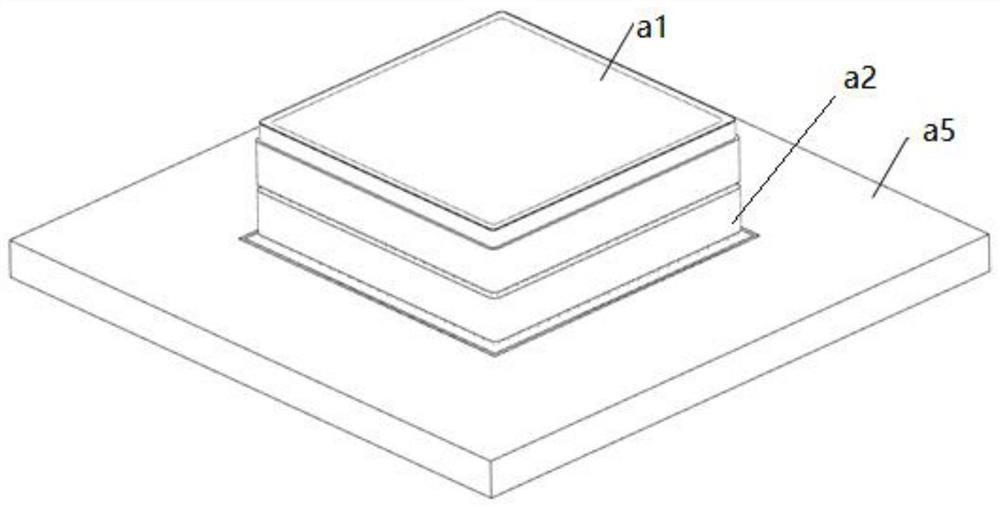

[0025] Combine figure 1 , A low-laundering bilateral stacked ceramic system of the present embodiment includes a top layer package assembly A1, a bottom package assembly A3, a bottom layer package assembly A1, a top package assembly A1, and a bottom package assembly A3, a top package assembly Between the inter-layer BGA solder ball A2; the bottom layer package assembly A3 is connected to the printed plate A5 by the underlying BGA solder ball A4;

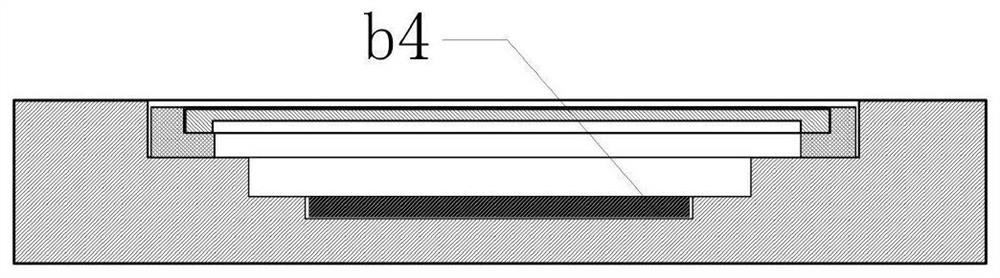

[0026] The bottom layer package assembly A3 is composed of a bottom layer cover B1, a bottom layer frame B2, a bottom ceramic base B3, a bottom layer chip, and a sheet B4; the bottom ceramic base B3 is composed of high temperature co-burning ceramic material; the bottom surrounding Box B2, the bottom layer cover B1 is made of a taperable material, and the bottom layer frame B2 is soldered in the underlying cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com