Activated carbon fiber sheet for automobile adsorption tank

A technology of activated carbon fiber and adsorption tank, which is applied to the chemical characteristics of fibers, motor vehicles, carbon compounds, etc., can solve the problems of difficult desorption of gasoline, and achieve the effect of high adsorption and desorption performance, excellent adsorption and desorption performance, and easy disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0128] Carbonizing and activating the raw material sheet holding either or both of the phosphoric acid-based catalyst or the organic sulfonic acid-based catalyst; and

[0129] In order to make the density of the activated carbon fiber sheet become 0.030~0.200g / cm 3 way to adjust.

[0130] 3-1. Preparation of raw material sheet (precursor)

[0131]

[0132] Examples of fibers constituting the raw material sheet include cellulose-based fibers, pitch-based fibers, PAN-based fibers, phenolic resin-based fibers, and preferably cellulose-based fibers.

[0133]

[0134] Cellulosic fibers are fibers composed mainly of cellulose and / or derivatives thereof. The cellulose and cellulose derivatives may be any of chemically synthesized, plant, regenerated cellulose, cellulose produced by bacteria, and the like. As the cellulose-based fibers, for example, fibers formed from plant-based cellulose substances obtained from trees and the like, and fibers obtained by chemically treating p...

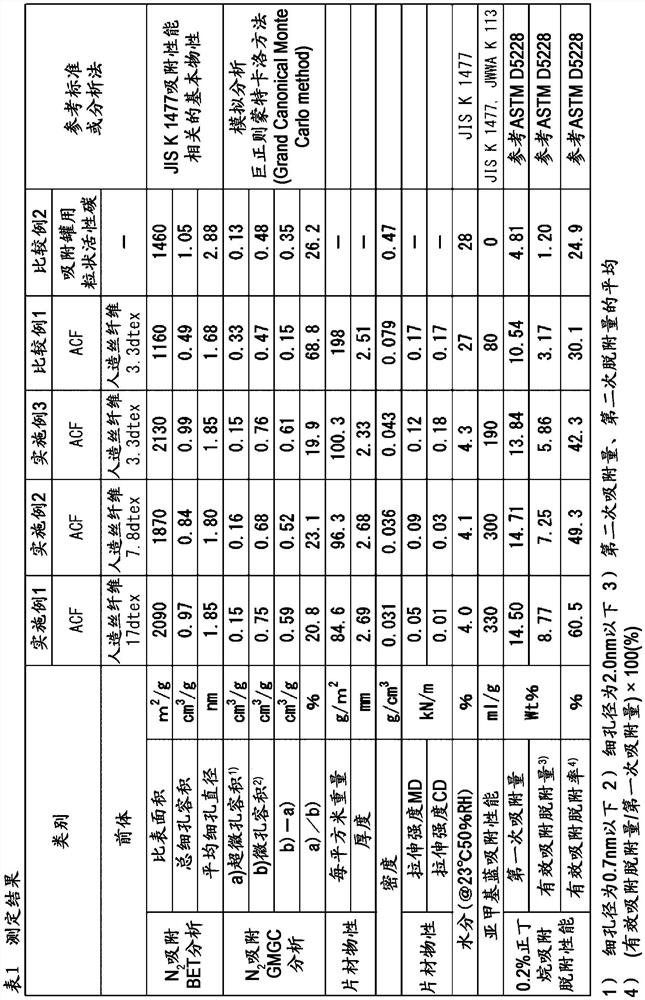

Embodiment 1

[0232] The weight per square meter formed by rayon fibers (17.0dtex) is 300g / m 2 The needle-punched nonwoven fabric is impregnated with 6-10% diammonium hydrogen phosphate aqueous solution, wrung out the liquid, and then dried to allow 8-10% by weight to adhere. The obtained pretreated nonwoven fabric was heated up to 900° C. in a nitrogen atmosphere over 50 minutes, and kept at this temperature for 4 minutes. Next, at this temperature, activation treatment was performed for 18 minutes in a nitrogen stream containing water vapor having a dew point of 71°C.

Embodiment 2

[0234] Use a rayon fiber (7.8dtex) with a weight per square meter of 300g / m 2 The activated carbon fiber sheet of Example 2 was produced by the same method as in Example 1 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com