Manganese-containing sludge deep dehydration treatment agent and treatment method

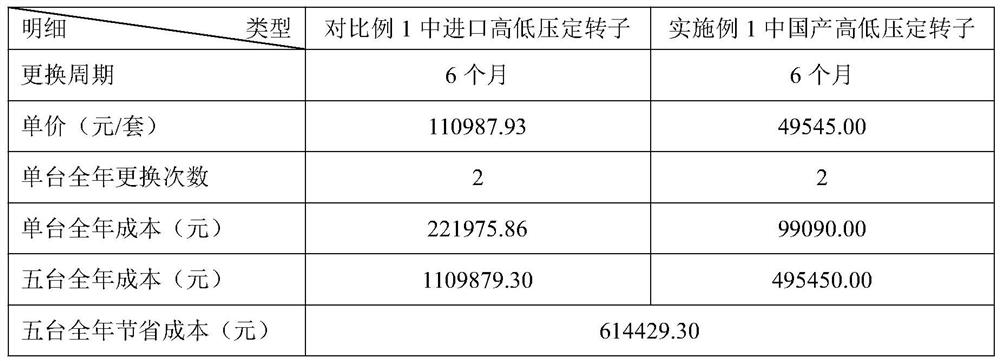

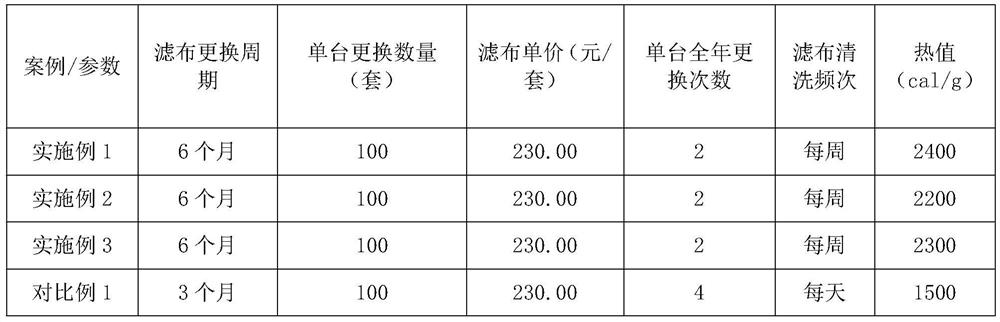

A technology of deep dehydration and treatment method, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. The problems such as the loss of accessories and other auxiliary materials can achieve the effect of obvious adsorption and bridging, stable cost control and reduction of loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for advanced dehydration of manganese-containing sludge, the treatment agent of the method includes basic aluminum chloride and polyquaternium, wherein the mass ratio of sludge, basic aluminum chloride and polyquaternium is 100:3- 10: 1.4-2.5; the sludge is manganese-containing sludge; the chain structure of the polyquaternium salt is branched, and the polyquaternium salt is produced by Dongguan Kaiwei Environmental Protection Materials Co., Ltd., and its model is KW3660. In this example, the mass ratio of sludge, basic aluminum chloride and polyquaternium is 100:6:2.3.

[0030] The processing method of the present embodiment comprises the following steps:

[0031] The first step, deploying sludge: obtain sludge, and adjust the moisture content of the sludge to 92%-96% to obtain sludge M;

[0032] The second step, preheating the sludge: Preheat the sludge M to 50°C at a stirring rate of 600r / min;

[0033] The third step, adding basic aluminum chloride: conti...

Embodiment 2

[0041] The difference between Example 2 and Example 1 is that the mass ratio of sludge, basic aluminum chloride and polyquaternium is 100:3:1.4; the constant temperature is 40°C; the dropping rate of basic aluminum chloride It is 0.3g / min; the dropping rate of polyquaternium is 0.16g / min.

Embodiment 3

[0042] The difference between Example 3 and Example 1 is that the mass ratio of sludge, basic aluminum chloride and polyquaternium is 100:10:2.5 (40:4:1); the constant temperature is 65°C; The dropping rate of aluminum chloride is 1g / min; the dropping rate of polyquaternium salt is 0.25g / min.

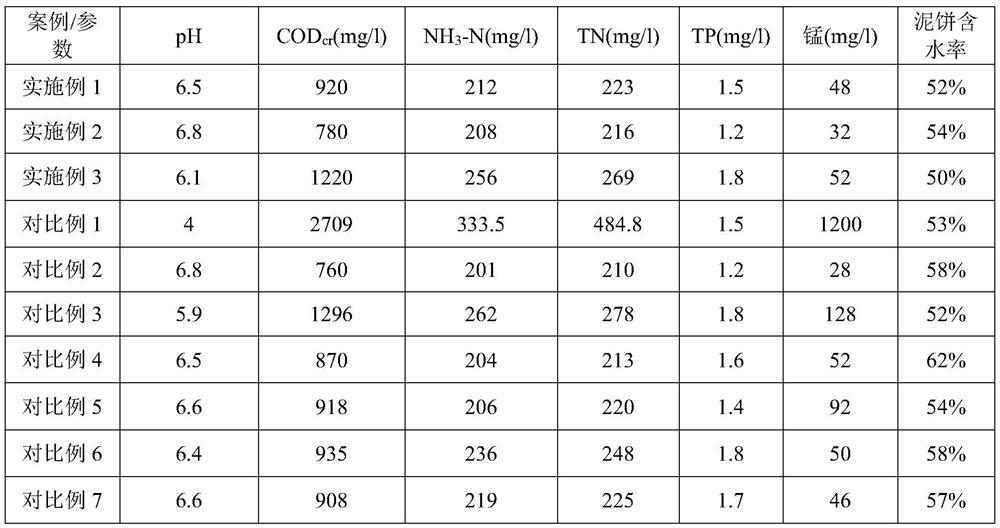

[0043] The filtrate and mud cake obtained in Example 2-3 are detected, as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com